Im Bereich der fortgeschrittenen Ingenieurtechnik und Fertigung hebt sich der Düsenring als ein wichtiges Bauteil hervor, insbesondere in Branchen wie Luft- und Raumfahrt, Automobilbau und Energieerzeugung. Dieser Artikel geht auf die Bedeutung des Düsenrings ein, wobei der Fokus auf seinem Design, seiner Funktion und der Wahl des Materials – Inconel 718 – liegt, das für seine herausragende Leistung unter extremen Bedingungen bekannt ist.

Ein Düsenring ist ein wesentlicher Bestandteil verschiedener mechanischer Systeme, einschließlich Gasturbinen, Strahltriebwerke und Raketenantriebssysteme. Seine Hauptfunktion besteht darin, den Fluss von Gasen oder Flüssigkeiten zu leiten und zu richten, um die Effizienz und Leistung des Systems zu optimieren. In Gasturbinen zum Beispiel übernimmt der Düsenring eine entscheidende Rolle bei der Beschleunigung der Abgasströme, was wiederum die Turbinenschaufeln antreibt und Energie erzeugt. Ähnlich wie in Luft- und Raumfahrtanwendungen hilft der Düsenring dabei, den Schub und die Richtung des Motors zu kontrollieren, um während des Fluges eine stabile und effiziente Betriebsweise sicherzustellen.

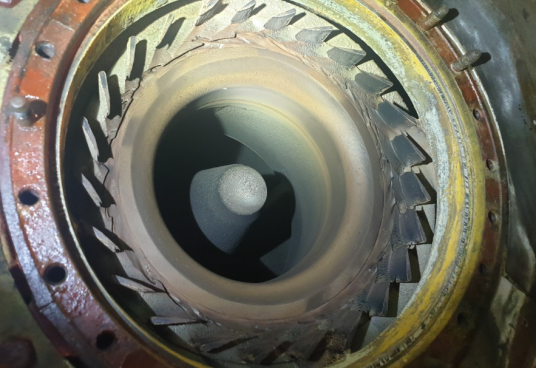

Die Gestaltung eines Düsenrings ist komplex und erfordert präzise Ingenieurarbeit, um eine optimale Leistung zu gewährleisten. Er besteht in der Regel aus einer Reihe von Schaufeln oder Blättern, die in einem Kreismuster angeordnet sind und den Fluss von Gasen oder Flüssigkeiten leiten. Die Form und das Abstand dieser Schaufeln werden sorgfältig berechnet, um Turbulenzen zu minimieren und die Geschwindigkeit der Abgasströme zu maximieren. Diese präzise Steuerung ist essenziell für die Effizienz und Zuverlässigkeit des gesamten Systems.

Beim Auswahl von Materialien für hochleistungs-fähige Komponenten wie den Düsenring müssen Ingenieure verschiedene Faktoren berücksichtigen, darunter Stärke, Korrosionsbeständigkeit, thermische Stabilität und Fertigungsfähigkeit. Inconel 718 ist ein nickelbasiertes Superalloy, das sich in diesen Bereichen hervorragend bewährt hat, wodurch es zur bevorzugten Wahl für viele kritische Anwendungen wird.

Eigenschaften von Inconel 718:

Die Fertigung eines Düsenrings aus Inconel 718 umfasst mehrere Schritte, die jeweils darauf abzielen, die höchste Qualität und Leistung sicherzustellen:

Ein bemerkenswertes Beispiel für den Einsatz von Inconel 718 Düsenringen ist die Luft- und Raumfahrtindustrie. Ein führender Hersteller von Luft- und Raumfahrttechnik hat kürzlich Inconel 718 Düsenringe in die neueste Generation ihrer Strahltriebwerke integriert. Die Ergebnisse waren bemerkenswert:

Der Düsenring, wenn er aus Inconel 718 hergestellt wird, steht für eine Spitzenleistung im Ingenieurwesen. Seine Kombination aus hoher Festigkeit, Korrosionsbeständigkeit und thermischer Stabilität macht ihn unverzichtbar in Anwendungen, in denen Leistung und Zuverlässigkeit oberste Priorität haben. Ob in der Luft, am Boden oder in industriellen Anlagen, der Düsenring spielt weiterhin eine entscheidende Rolle bei der Förderung der Technologie und dem Ausloten dessen, was möglich ist.

Für weitere Informationen zu Inconel 718-Düsenringen und anderen hochleistungsfaähigen Komponenten kontaktieren Sie bitte unsere Firma bei OBT. Wir spezialisieren uns darauf, maßgeschneiderte technische Lösungen für eine Vielzahl von Industrien bereitzustellen und sicherzustellen, dass Ihre Projekte den höchsten Qualitäts- und Leistungsstandards entsprechen.

Bei OBT , wir verstehen die Bedeutung von Präzision und Zuverlässigkeit in hochleistungsfähigen Komponenten. Unser Team erfahrener Ingenieure und Techniker ist darauf ausgerichtet, innovative Lösungen anzubieten, die den einzigartigen Anforderungen unserer Kunden gerecht werden. Von der ersten Konzeption bis zur endgültigen Produktion arbeiten wir eng mit Ihnen zusammen, um sicherzustellen, dass jeder Aspekt des Prozesses auf Erfolg optimiert ist.

Egal ob Sie die Leistung Ihrer Luft- und Raumfahrtanlagen verbessern, die Effizienz Ihrer Stromerzeugungsanlagen erhöhen oder die Zuverlässigkeit Ihrer Automobilkomponenten optimieren möchten, wir verfügen über die Expertise und Ressourcen, um Ihnen bei der Erreichung Ihrer Ziele zu helfen. Kontaktieren Sie uns heute, um mehr über unsere Unterstützung bei Ihren Ingenieursprojekten und darüber zu erfahren, wie wir Ihnen helfen können, in Ihrer Branche Exzellenz zu erlangen.

Aktuelle Nachrichten

Aktuelle Nachrichten2024-12-31

2024-12-04

2024-12-03

2024-12-05

2024-11-27

2024-11-26

Unser professionelles Verkaufsteam freut sich auf Ihre Beratung.