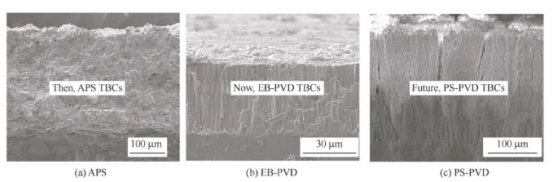

In gewissem Maße beeinflusst die Mikrostruktur des thermischen Barrierschichtsystems nicht nur die Wärmeisolierung, die Oxidationsbeständigkeit und andere Eigenschaften der Schicht, sondern bestimmt auch die Lebensdauer der Schicht. Die Mikrostruktur des thermischen Barrierschichtsystems hängt nicht nur von dem verwendeten Material ab, sondern auch von seinem Herstellungsprozess. Daher ist es ebenfalls wichtig, den geeigneten Herstellungsprozess je nach unterschiedlichen Anforderungen auszuwählen. Es gibt viele Möglichkeiten zur Herstellung von thermischen Barrierschichten, sie lassen sich jedoch hauptsächlich in zwei Kategorien unterteilen: einerseits die thermische Spritztechnik und andererseits die physikalische Dampfphasenabscheidung. Dabei umfasst die thermische Spritztechnik hauptsächlich die supersonische Spritzmethode, die Plasmabeschichtung, die Explosionsbeschichtung und andere. Die durch thermische Spritztechnik hergestellte Beschichtung ist schuppig. Die physikalische Dampfphasenabscheidung basiert hauptsächlich auf Elektronenstrahlphysikalischer Dampfphasenabscheidung (EB-PVD), wobei die hergestellte Beschichtung säulenförmig ist. Die keramische Schicht des thermischen Barrierschichtsystems wird oft mittels Elektronenstrahlphysikalischer Dampfphasenabscheidung, atmosphärischer Plasma-Spritztechnik und anderen Methoden hergestellt. Die metallische Bindeschicht verwendet hauptsächlich thermische Spritztechnologien wie atmosphärische Plasma-Spritztechnik (APS), Niederdruck-Plasma-Spritztechnik (LPPS) und supersonische Flammspritztechnik (HVOF) [40]. Bis heute sind APS und EB-PVD die wichtigsten Methoden zur Herstellung von thermischen Barrierschichten für Gasturbinen.

APS ist eine Art von Gleichstrombogen, der durch die Sprühdüse erzeugt wird, um Ar, He, N2 und andere Gase in Plasmaströme umzuwandeln, sodass das durch das Trägergas transportierte keramische Pulver und Metallpulver schnell erhitzt und zu geschmolzenen oder teilweise geschmolzenen Partikeln verdampft. Technologie zur Bildung eines Beschichtungs auf der Oberfläche einer Superallegematrix, indem es unter dem Einfluss eines elektrischen Feldes mit großer kinetischer Energie (80 ~ 300 m/s) aufschlägt [42]. Die durch APS-Technologie hergestellte thermische Barrierebeschichtung besteht aus zahlreichen übereinanderliegenden Partikeln, und die Matrix ist hauptsächlich mechanisch an die laminare Mikrostruktur gebunden, die viele parallel zur Legierungs-Matrix verlaufende Defekte enthält, wie Poren und Mikrorisse (wie in Abbildung 2 gezeigt). Die Gründe für die Bildung sind folgende: Unter Hochtemperaturbedingungen schmilzt die Keramik oder das Metall zu geschmolzenen Partikeln, die einige Umgebungs gases enthalten werden, aber die Abkühlrate der Beschichtung ist sehr hoch, was dazu führt, dass die im Schmelzprozess gelösten Gase nicht rechtzeitig kondensieren können und dadurch Poren entstehen; Gleichzeitig führt eine unzureichende Verbindung zwischen den geschmolzenen Partikeln auch zur Bildung von Poren und Rissen in der Beschichtung. Daher hat die durch APS hergestellte thermische Barrierebeschichtung bei hoher Porosität gute Wärmedämmleistungen, aber ihre Nachteile sind ein unzureichendes Dehnungsverhalten und eine schlechte Wärmechocksbeständigkeit [43], und sie wird hauptsächlich für Bauteile mit relativ gutem Arbeitsumfeld verwendet. Darüber hinaus ist APS kostengünstig herzustellen, daher kann es auf größere Bauteile angewendet werden.

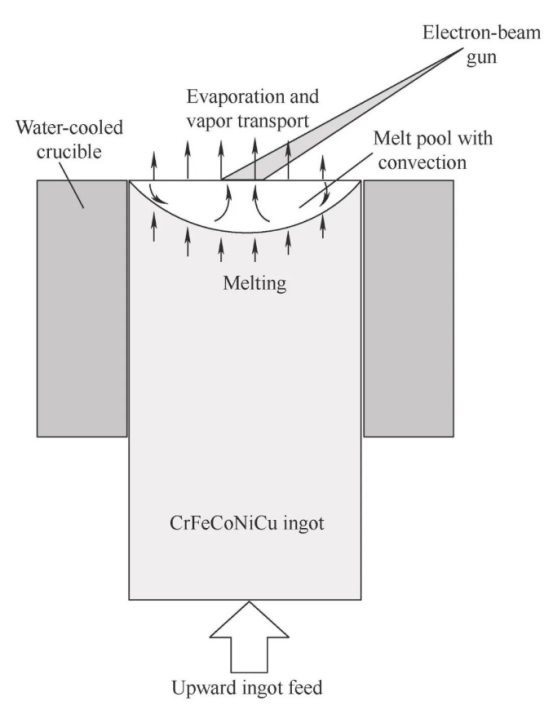

EB-PVD ist eine Technologie, die einen hochenergetischen Elektronenstrahl verwendet, um das Beschichtungspulver in einer Vakuumkammer zu erhitzen und auf der Oberfläche des Pulvers einen Schmelzpool zu bilden, um das keramische Pulver zu verdampfen und es im atomaren Zustand auf der Oberfläche des Substrats abzusetzen, um eine Wärmeschutzbeschichtung [45] zu bilden, wie in Abbildung 3 gezeigt. Die Struktur der EB-PVD-Beschichtung ist eine senkrecht zur Legierungs-Matrix ausgerichtete säulenförmige Kristallstruktur, und die Verbindung zwischen Beschichtung und Matrix erfolgt hauptsächlich metallurgisch. Die Oberfläche ist nicht nur glatt, sondern auch gut dicht, daher weist sie eine hohe Bindungsstärke, Dehnungstoleranz und Wärmechocksicherheit auf. Sie wird hauptsächlich für Bauteile mit strenger Betriebsumgebung angewendet, wie Gasturbinenrotorschaufeln. Allerdings ist die Herstellungskosten der EB-PVD-Beschichtung teuer, und nur dünne Beschichtungen können hergestellt werden, wobei an die Bauart der Teile bestimmte Anforderungen gestellt werden, sodass sie selten in Gasturbinen eingesetzt wird.

Die beiden oben genannten Herstellungsverfahren sind bereits sehr reif, haben jedoch weiterhin eigene Probleme, wie in Tabelle 2 gezeigt. In den letzten Jahren verbessern und entwickeln relevante Forscher fortlaufend neue Verfahren zur Herstellung von Wärmedämmbeschichtungen. Derzeit hebt sich unter den gebräuchlichen neuen Verfahren zur Herstellung von Wärmedämmbeschichtungen besonders die Technologie der Plasmabeschichtung durch physikalische Dampfphasenabscheidung (PS-PVD) hervor, die als eines der vielversprechendsten und effektivsten Verfahren zur Herstellung von Wärmedämmbeschichtungen gilt.

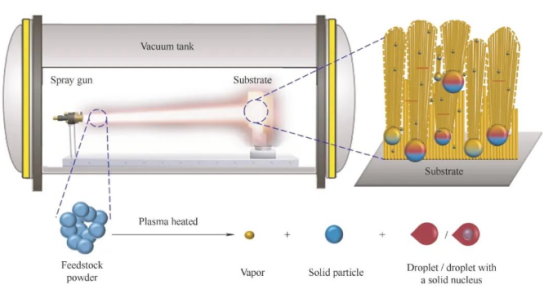

Die PS-PVD-Technologie wurde auf der Basis des Niederdruck-Plasmasprays entwickelt. Die durch diese Methode hergestellte Beschichtungsstruktur besteht aus Federn und Säulen, und die Poren in der Beschichtung sind zahlreich und die Lücken groß, wie in Abbildung 4 dargestellt. Daher hat die PS-PVD-Technologie das Problem der unzureichenden Wärmedämmung von EB-PVD-Beschichtungen und der schlechten Wärmechockschutz von APS-Beschichtungen verbessert. Die durch PS-PVD-Technologie hergestellte thermische Barrierebeschichtung weist eine hohe Bindungsstärke, gute Wärmedämmleistung und guten Wärmechockschutz auf, aber schlechte Korrosions- und Oxidationsbeständigkeit gegenüber CMAS. Auf dieser Grundlage schlugen ZHANG et al. [41] eine Methode zur Modifizierung der PS-PVD-7YSZ-Thermalbarrierbeschichtung mit Al2O3 vor. Die Versuchsergebnisse zeigen, dass die Oxidationsbeständigkeit und die CMAS-Korrosionsbeständigkeit der durch PS-PVD-Technologie hergestellten 7YSZ-Thermalbarrierbeschichtung durch Aluminiummodifizierung gesteigert werden kann.

Aktuelle Nachrichten

Aktuelle Nachrichten2024-12-31

2024-12-04

2024-12-03

2024-12-05

2024-11-27

2024-11-26

Unser professionelles Verkaufsteam freut sich auf Ihre Beratung.