As a key component to achieve the performance of aero-engines, blades have typical characteristics such as thin-walled, special-shaped, complex structures, difficult materials to process, and high requirements for processing accuracy and surface qual...

Read More

Load characteristics and calculation status of compressor and turbine disks of aircraft engines Although there are differences in the functions and structures of compressor and turbine rotors, in terms of strength, the working conditions of the wheel...

Read More

Research progress on aerodynamic performance of aircraft engine combustion chamber based on large eddy simulation The combustion chamber is one of the core components of an aircraft engine, and the aerodynamic performance of the combustion chamber pl...

Read More

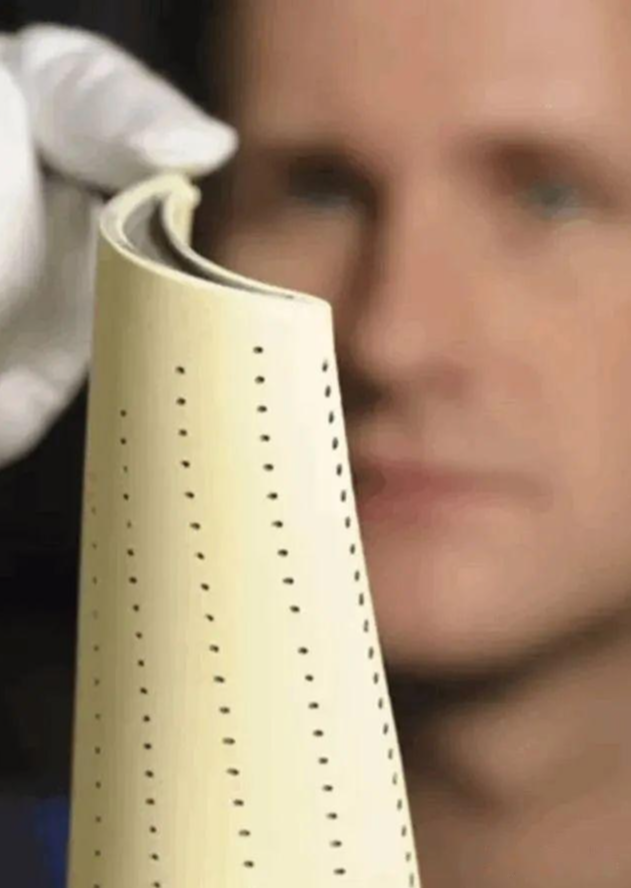

Guide vanes are essential components in gas turbine engines, meticulously designed to direct the flow of scorching, high-pressure gases onto the turbine blades. The precision of their design and the selection of materials are vital to enhan...

Read More

Guide vanes are critical components in gas turbine engines, responsible for directing the flow of hot, high-pressure gases onto the turbine blades. Their precise design and exceptional material properties are paramount to the engine’s effi...

Read More

Guide Vanes, a critical component in the aerospace and industrial sectors, play a pivotal role in controlling and directing airflow or fluid flow within engines, turbines, and other mechanical systems. These components are essential for optimizing th...

Read More

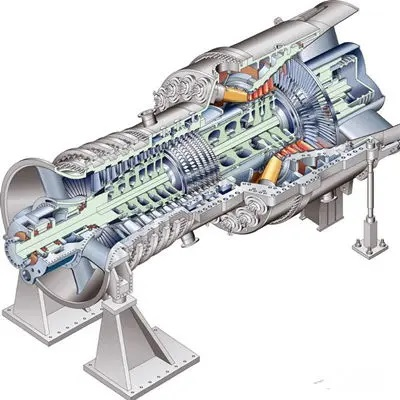

1 Development of aviation gas turbine engines As the performance requirements for aircraft for transportation, military, production and other purposes increased, the earliest piston engines could no longer meet the needs of high-speed flight. Therefo...

Read More

The principle of how aircraft engine high-pressure turbine rotor blades are manufactured is very simple, but the various parameters in this process require a lot of experiments to obtain the parameters of each node, the composition of auxiliary mater...

Read More

The aircraft engine is the "heart" of the aircraft and is also known as the "crown jewel of industry". Its manufacturing integrates many cutting-edge technologies in modern industry, involving materials, mechanical processing, thermodynamics and othe...

Read More

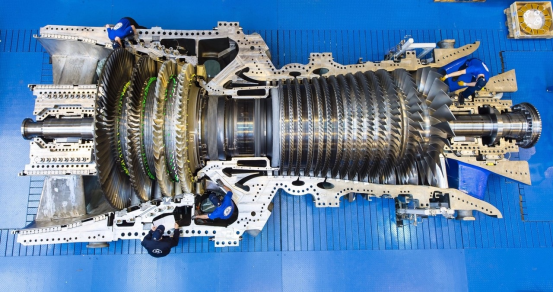

Axial flow turbine structure A turbine is a rotary power machine that converts the enthalpy of a working fluid into mechanical energy. It is one of the main components of aircraft engines, gas turbines, and steam turbines. The energy conversion betwe...

Read More

Development History and Trends of Turbine Blades Turbine blades are divided into two categories: turbine guide blades and turbine working blades. The main function of turbine guide vanes is to adjust the flow direction of the exhaust gas from the com...

Read More

As a modern key power mechanical equipment, gas turbine efficiency improvement is crucial to energy utilization and industrial development. In order to enhance the performance of gas turbines, researchers have taken various measures in the design and...

Read More Hot News

Hot News2024-12-31

2024-12-04

2024-12-03

2024-12-05

2024-11-27

2024-11-26

Our professional sales team are waiting for your consultation.