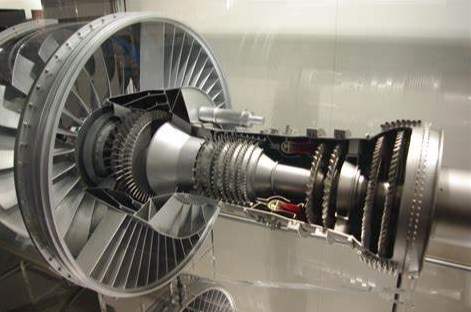

W nowoczesnych przemyłach lotniczym i energetycznym turbiny są nieodzowne, pełniąc rolę serca silników lotniczych, elektrowni oraz wielu innych maszyn o wysokich wydajnościach. Jako kluczowy element tych systemów, łopatki turbin muszą wytrzymać ekstremalne warunki pracy, w tym narażenie na wysokie temperatury, ciśnienia oraz intense siły odśrodkowe generowane przez szybkie obroty, jednocześnie zachowując długoterminową wydajność i niezawodność. Aby spełnić te surowe wymagania, producenci stale poszukują zaawansowanych materiałów i innowacyjnych technik produkcyjnych. Jedną z takich technik, która zdobyła znaczącą popularność, jest wyrabianie równoziarnistych krystalizatów.

Co to jest wyrabianie równoziarnistych krystalizatów?

Lity krystaliczny równoosiowy to specjalistyczny proces solidyfikacji metali, w którym struktura mikrokrystaliczna składa się z względnie jednolitych, małych ziaren. Ta struktura, mimo że może poświęcić niektóre właściwości termiczne w porównaniu do materiałów solidyfikowanych kierunkowo lub pojedynczych krystalów, znacząco wzmacnia wytrzymałość mechaniczną i odporność materiału. Te cechy czynią go szczególnie odpowiednim dla złożonych części, takich jak łopatki turbinowe, gdzie opór na zmęczenie, rozprzestrzenianie się pęknięć oraz uszkodzenia od uderzeń jest kluczowy. Poprzez staranne kontrolowanie tempa chłodzenia podczas solidyfikacji oraz dodawanie odpowiednich substancji nukleujących do topionego materiału można promować tworzenie się drobnych, równomiernie rozłożonych krystalików równoosiowych, co prowadzi do lepszej ogólnej wydajności.

Przewagi lity krystalicznej równoosiowej

Zwiększone oporność na zmęczenie: Unikalna mikrostruktura równoważnych wyróbów odlewniczych zapewnia poprawioną trwałość pod cyklicznym obciążeniem, czyniąc je bardziej odpornymi na awarie związane ze zmęczeniem.

Poprawiona plastyczność i wytrzymałość: W porównaniu do innych metod odlewania, materiały równoległe prezentują większą wytrzymałość na pękanie i plastyczność, co pozwala im lepiej absorbować i rozprowadzać naprężenia bez pęknięcia.

Wielofunkcyjność: Ta metoda może być skutecznie stosowana w różnych systemach stopowych, w tym materiałów o wysokich wydajnościach, takich jak superalemony niklowe, które są powszechnie używane w zastosowaniach wiązkowych turbin dzięki swojej doskonałej wytrzymałości przy wysokich temperaturach i odporności na korozyję.

Kosztowność: Choć początkowe inwestycje w technologię i sprzęt mogą być znaczne, redukcja kosztów konserwacji i przedłużenie czasu użytkowania przyczyniają się do niższych łącznych kosztów posiadania w cyklu życia produktu.

Badanie przypadków klientów

Występny producent silników lotniczych ostatnio rozpoczął inicjatywę w celu poprawy wydajności łopatek turbinowych dla swojej najnowszej generacji silników odrzutowych komercyjnych. Po przeprowadzeniu rozległych badań firma postanowiła zastosować technologię odlewniczą krystalizacji równoosiowej, aby ulepszyć swój istniejący projekt. Zespół projektowy rozpoczął od optymalizacji wyboru materiału, wprowadzając odpowiednią ilość elementów nukleujących do składu stopu, aby ułatwić tworzenie się struktury drobnoziarnistej. Następnie wykorzystano oprogramowanie do symulacji komputerowych w celu przewidzenia optymalnych warunków wlewania, zapewniając idealny gradient temperatury w formie, aby osiągnąć pożądane mikrostruktury. Wreszcie, nowy projekt poddano surowym testom i walidacji, aby upewnić się, że spełnia wszystkie obowiązujące standardy branży.

Wyniki były impresyjne. Nowo wyprodukowane łopatki turbinowe, wytwarzane za pomocą metody odlewnictwa kryształów równoosiowych, nie tylko osiągnęły obniżenie masy o 5%, ale również wykazały zwiększenie trwałości o 20% przy tych samych warunkach eksploatacyjnych. Ponadto produkty pomyślnie przeszły wszystkie niezbędne procedury certyfikacji, co pozwoliło firmie zabezpieczyć większą część rynku i utrwalić swoją pozycję jako lidera w tej dziedzinie. Ta historia sukcesu podkreśla kluczowe znaczenie odlewnictwa kryształów równoosiowych w napędzaniu postępów technologicznych w przemyśle.

Podsumowanie

W miarę jak technologia kontynuuje swoje postępy, odlewnictwo krystaliczne o osi równoległej staje się kluczową technologią w produkcji wysoce wydajnych łopatek turbinowych. Nie tylko pomaga przedsiębiorstwom przekraczać trudne do rozwiązania wyzwania techniczne za pomocą tradycyjnych metod produkcyjnych, ale również tworzy podstawy dla rozwoju jeszcze bardziej efektywnych i niezawodnych systemów energetycznych w przyszłości. Dzięki swojej zdolności do poprawy właściwości materiałów i obniżenia kosztów ogółem, odlewnictwo krystaliczne o osi równoległej ma zagrać kluczową rolę w kształtowaniu nowej generacji rozwiązań lotniczych i energetycznych, zapewniając, że te krytyczne komponenty będą dalej działać na najwyższym poziomie nawet w najtrudniejszych warunkach.

Skontaktuj się z nami

Jeśli masz silne zainteresowanie naszymi produktami, nie wahaj się natychmiast z nami skontaktować. Nasz profesjonalny zespół z przyjemnością ci służyć będzie, odpowiedzieć na każde twoje pytanie, dostarczyć szczegółowych informacji o produktach i zaproponować personalizowane rozwiązania.

Gorące wiadomości

Gorące wiadomości2024-12-31

2024-12-04

2024-12-03

2024-12-05

2024-11-27

2024-11-26

Nasz profesjonalny zespół sprzedaży czeka na Twoje zapytanie.