In the realm of modern engineering and technology, turbine wheels stand as remarkable feats of innovation and power. These mechanical wonders play a crucial role in various industries, driving progress and efficiency like never before.

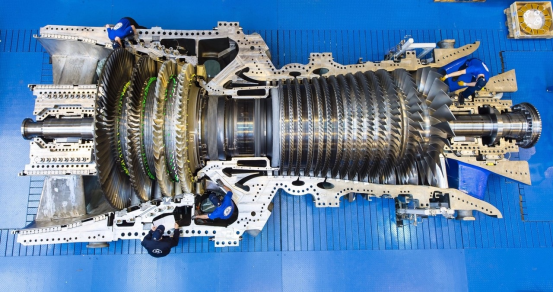

Turbine wheels are at the heart of turbines, which are essentially devices that convert the energy of a flowing fluid (such as gas, steam, or water) into mechanical energy. The turbine wheel, with its precisely designed shape and construction, is the key component that makes this energy conversion possible.

One of the most common applications of turbine wheels is in the power generation industry. Gas turbines and steam turbines are widely used to generate electricity. The high-speed rotation of the turbine wheel drives a generator, producing the electrical power that lights up our homes, powers our industries, and keeps our modern world running. These turbine wheels are designed to withstand extreme temperatures and pressures, ensuring reliable and continuous operation.

In addition to power generation and aerospace, turbine wheels are also used in other industries such as oil and gas, marine propulsion, and industrial processes. In the oil and gas industry, turbine wheels are used in gas compressors and pumps to move natural gas and other fluids through pipelines. In marine propulsion, turbine wheels are used in gas turbine-powered ships to provide high-speed and efficient transportation. In industrial processes, turbine wheels are used in various applications such as air compression, refrigeration, and chemical processing.

In the aerospace industry, turbine wheels are integral to jet engines. The power and efficiency of these wheels enable aircraft to reach high speeds and altitudes. The materials used in aerospace turbine wheels are highly advanced and lightweight, yet incredibly strong. They must be able to endure the harsh conditions of high-altitude flight, including rapid changes in temperature and pressure.

The automotive industry also benefits from turbine wheels.Turbochargers, which use a small turbine wheel to increase the power and efficiency of internal combustion engines, are becoming increasingly popular. By forcing more air into the engine, turbochargers can significantly enhance performance and fuel economy.

The design and manufacturing of turbine wheels is a complex and precise process. Engineers use advanced computer simulations and modeling techniques to optimize the shape and performance of the wheel. Materials such as high-strength alloys, ceramics, and composites are selected for their durability, heat resistance, and light weight.

Precision machining and quality control are essential to ensure that each turbine wheel meets the strictest standards. Any imperfections or deviations can lead to reduced performance or even failure, so every step of the manufacturing process is carefully monitored and tested.

In addition to their technical capabilities, turbine wheels also have a significant environmental impact. By increasing the efficiency of power generation and transportation, they help reduce energy consumption and emissions. As the world continues to seek sustainable solutions, turbine wheels will play an even more important role in the transition to cleaner energy sources.

In conclusion, turbine wheels are truly remarkable engineering marvels. Their power, efficiency, and versatility make them essential components in a wide range of industries. From powering our cities to propelling our airplanes and enhancing our vehicles, turbine wheels are driving progress and shaping the future. As technology continues to advance, we can expect even more innovative applications and improvements in the design and performance of these incredible devices.

At our company, we take immense pride in offering not only top-notch turbine wheels but also a comprehensive range of professional products and services. Our team of dedicated experts is committed to ensuring that every aspect of your turbine wheel needs is met with precision and excellence.

We understand that in the highly competitive industries that rely on turbine wheels, having reliable products and exceptional service is crucial. That's why we go above and beyond to provide solutions that are tailored to your specific requirements. Whether you're in the power generation sector, aerospace field, or any other industry that demands high-performance turbine components, we have the expertise and resources to deliver.

Our product line is crafted with the utmost care and attention to detail. We use only the highest quality materials and employ advanced manufacturing techniques to ensure durability, efficiency, and performance. From the design stage to the final inspection, every step is carried out with precision and a focus on quality.

In addition to our outstanding products, our service offerings are second to none. Our customer service team is always ready to answer your questions, provide technical support, and guide you through the selection and installation process. We believe in building long-term relationships with our clients, and we strive to exceed your expectations at every turn.

If you're looking for a reliable partner for your turbine wheel needs, look no further. Contact us today and let us show you how our professional products and services can make a significant difference in your operations. We're eager to hear from you and start a journey of collaboration and success.

Hot News

Hot News2024-12-31

2024-12-04

2024-12-03

2024-12-05

2024-11-27

2024-11-26

Our professional sales team are waiting for your consultation.