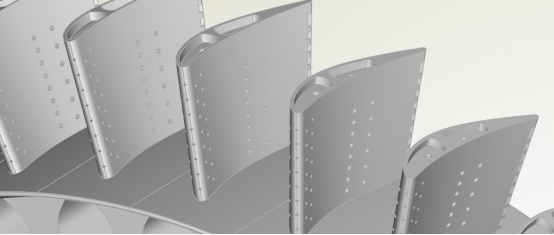

The most common models of Udimet thermostatic forging blades are Udimet 500, Udimet 520, Udimet 188, and Udimet 720. In the forging of turbine blades, we use the material of Udimet 720. Udimet 720 blades are high-quality forging products launched by us and are manufactured under constant temperature and high temperature environment.In this process, turbine blades improve their microstructure and stable temperature helps to obtain uniform and fine microstructure. The mechanical properties such as strength, toughness and fatigue life of forged blades are improved.

Our isothermal forging can manufacture Udimet 500, Udimet 520, Udimet 188 and Udimet 720 and other isothermal forging products, with rich production experience and mature production technology.Udimet 720 is a nickel-based high-temperature alloy with excellent mechanical properties and resistance to oxidation and corrosion.It performs well in high-temperature and high-stress environments, so it is widely used in the aerospace industry, especially in key components of turbine engines such as turbine blades, disks and shafts.

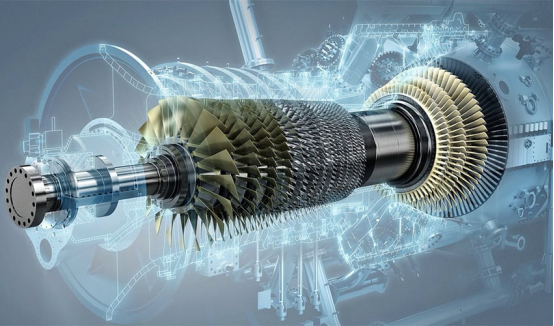

Thermostatic forging is a sophisticated manufacturing process specifically designed for the production of high-performance superalloy turbine blades.This advanced technique involves precisely controlling the temperature and deformation rate to optimize the material's microstructure, ensuring superior mechanical properties and extended service life under extreme operating conditions.By carefully managing the thermal environment during the forging process, manufacturers can achieve uniform grain structures and reduce internal stresses, which are critical for components that must withstand high temperatures, pressures, and rotational speeds. The result is a highly reliable and efficient turbine blade, capable of meeting the demanding requirements of modern aerospace and power generation industries.

1.Tempering treatment:tempering treatment of superalloy materials to achieve better processing performance.

2.Pre-heating: The material is pre-heated by electric furnace, which needs to be evenly heated to reduce the processing intensity.

3.Surface treatment and lubricant application: Surface treatment of alloy bar material as required, and spray or dip glass lubricant to reduce friction and heat loss during forging.

4.Open die forging: the processed superalloy material is put into the mold for forging.

Isothermal forging is an advanced manufacturing process used to produce components with exceptional mechanical properties, particularly for high-temperature applications such as superalloy turbine blades. Unlike conventional forging, where the workpiece and the die may be at different temperatures, isothermal forging maintains both the workpiece and the die at a constant, uniform temperature throughout the entire process. This temperature control is typically achieved using heated dies and a controlled atmosphere or inert gas environment.

Enhanced Material Properties: By maintaining a consistent temperature, the microstructure of the material can be more precisely controlled, leading to improved strength, ductility, and fatigue resistance.

Reduced Grain Growth: The controlled temperature minimizes excessive grain growth, which can occur in conventional forging due to temperature variations. This results in a finer, more uniform grain structure.

Lower Forging Pressures: Isothermal conditions allow for the deformation of materials at lower pressures, reducing the risk of defects and improving the overall quality of the forged part.

Improved Surface Finish: The use of heated dies and controlled conditions often leads to better surface finish, reducing the need for subsequent machining operations.

Increased Tool Life: Operating at a consistent temperature reduces thermal cycling and stress on the dies, extending their life and reducing maintenance costs.

This process is particularly advantageous for producing complex shapes and thin-walled sections, making it ideal for the aerospace, power generation, and other industries where performance and reliability are paramount.

1.High high temperature strength: Udimet 720 is a nickel-based high temperature alloy with high high temperature strength. lt can maintain good mechanical properties in high temperature environment and is suitable for manufacturing parts such as aircraft engine turbine blades working under high temperature conditions.

2.Good fatigue and creep resistance: This enables it to maintains tructurals tability and reliability under long-term cyclic loads and high temperatures.

3.Good anti-oxidation and corrosion resistance: helps to resist the effects of oxidation and corrosion in harsh working environments and extend the service life of the blades.

1.High temperature strength

Maintain high strength andcreep resistance in hightemperature environments.

2.Antioxidation and corrosion resistance

Excellent durability in hightemperature oxidation and corrosion environments.

3.Excellent fatigue performance

Good fatigue resistance under high cycle fatigueconditions.

4.Good processability

he blade has good processability and surface quality through constant temperature forging and subsequent last treatment.

The factory covers an area of over 20,000 square meters,and professional R & D team.

Nickel-based alloy titanium alloy gas turbine aviation and nuclear powerplant casting factory

Authorized Trade Assurance $1100,000.00 to guarantee quality and shipment

We can produce products from 0.1g to 17,000kg, and sizes from lessthan 1 cubic centimete to over 14 cubic meters.

Spectrometer, X-ray, CMM, tensile test and other test reports can be selected

Cooperation with more than 40 countries

Hot News

Hot News2024-12-31

2024-12-04

2024-12-03

2024-12-05

2024-11-27

2024-11-26

Our professional sales team are waiting for your consultation.