Home / PRODUCTS / Superalloy / Monel Material

Monel 400 is a nickel-copper alloy also known as UNS N04400. It is one of the earliest Monel alloys developed, consisting of about 67% nickel and 33% copper, and also contains small amounts of elements such as iron, manganese, silicon and carbon. Monel 400 has excellent corrosion resistance and good mechanical properties, making it widely used in many different applications.

1. The corrosion resistance of Monel is generally superior to that of nickel and copper. It is more resistant to corrosion from reducing media than pure nickel, and is more resistant to corrosion from oxidizing media than pure copper. It has excellent corrosion resistance to sulfuric acid, phosphoric acid and carbon. good. It is particularly resistant to hydrochloric acid corrosion and has excellent corrosion resistance to hot concentrated alkali. Monel400 alloy has excellent corrosion resistance in fluorine gas, hydrochloric acid, sulfuric acid, hydrofluoric acid and their derivatives.

At the same time, it is more corrosion-resistant than copper-based alloys in seawater. Monel400 is a deformable nickel-copper nickel-based alloy. It has good resistance to seawater corrosion and chemical corrosion, and has strong resistance to chloride stress corrosion cracking. This alloy is one of the few that can be used in fluorides. It has good resistance to oxide stress cracking corrosion in hydrofluoric acid and fluorine gas media, such as seawater and salt water environments. Monel 400 also has very good corrosion resistance in moderately concentrated alkaline and salt solutions. In cooler alkaline environments, the alloy is used in weak acid environments such as sulfur and hydrogen fluoride.

2. Acid medium: Monel400 is corrosion-resistant in sulfuric acid with a concentration of less than 85%. Monel400 is one of the few important materials that can withstand hydrofluoric acid.

3. Water corrosion: Monel400 alloy not only has excellent corrosion resistance under most water corrosion conditions, but also pitting corrosion, stress corrosion, etc. are rarely found, and the corrosion rate is less than 0.025mm/a.

4. High-temperature corrosion: The maximum temperature of Monel400's continuous operation in the air is generally around 600°C. In high-temperature steam, the corrosion rate is less than 0.026mm/a. Ammonia: Due to the high nickel content of Monel400 alloy, it can withstand corrosion under anhydrous ammonia and ammoniation conditions below 585°C.

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.30 | 0.50 | 2.00 | - | 0.024 | - | 63.0 | - | 28.0-34.0 |

| Others | N≤ | Al≤ | Ti≤ | Fe≤ | Co≤ | V≤ | W≤ | Nb≤ |

| - | - | - | 2.50 | - | - | - | - |

product

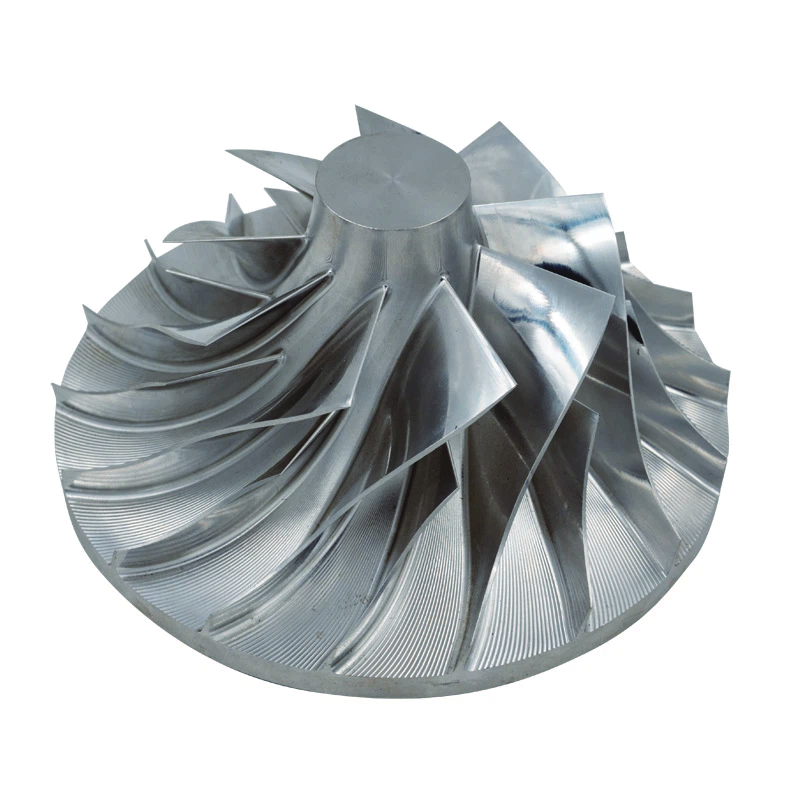

turbine wheel

turbine blade

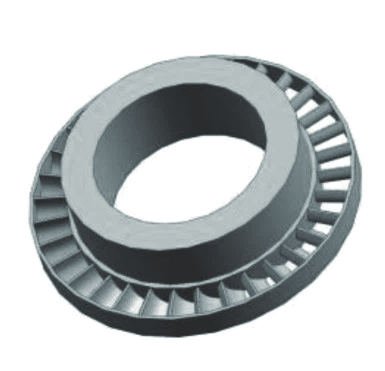

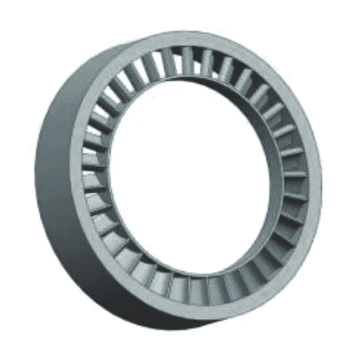

nozzle ring

compressor blade

guide vanes

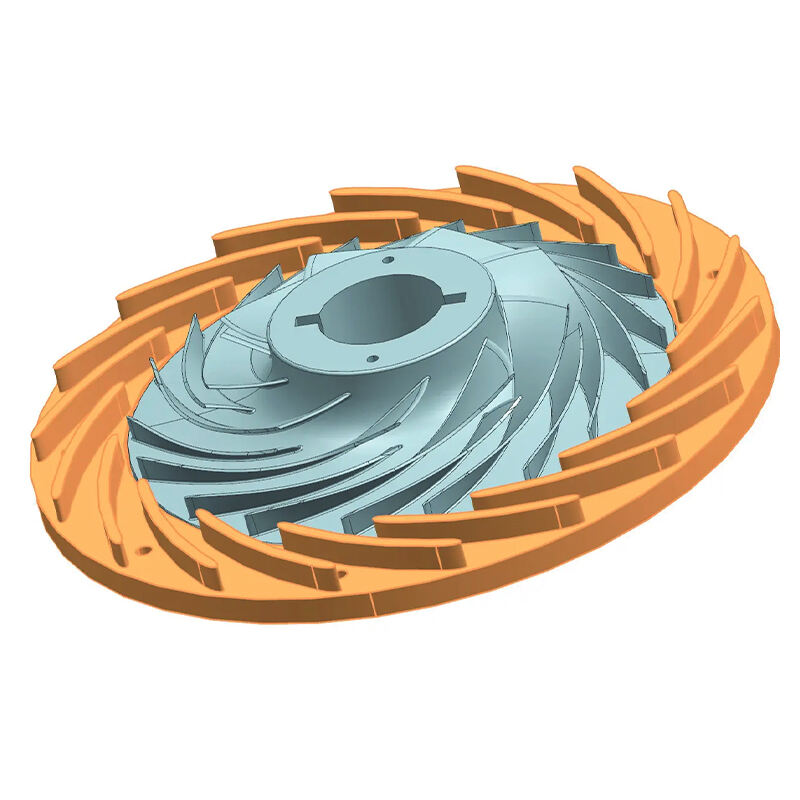

diffuser

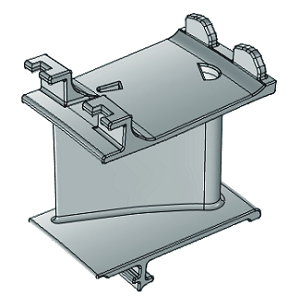

Segment

Turbine Rotor

Turbine Stator

Monel sheet

Monel pipe

Monel rod

Monel bolt and nut

Monel Fasteners

Monel wire

spring

According to drawings or samples

main usage scenarios of Monel 400:

Seawater application: Monel 400 has excellent seawater corrosion resistance, so it is often used in various applications in marine environments, such as seawater treatment equipment, marine ship parts and devices, etc.

Chemical industry: Monel 400 has strong corrosion resistance to alkaline media and chlorides, so it is used in the chemical industry to manufacture chemical processing equipment, oil refining equipment, acid-base tanks, etc.

Oil and gas industry: Monel 400 is commonly used to manufacture equipment such as pipelines, valves, heat exchangers and pumps in seawater and acidic environments. It is widely used in oil extraction, chemical processing and natural gas production.

Aerospace industry: Because Monel 400 has good mechanical properties and corrosion resistance, it is often used in the aerospace field to manufacture aircraft and spacecraft parts, such as engine parts, connectors and fasteners.

Food processing: Monel 400 has good resistance to corrosive substances in food and beverages, so it also has certain applications in the food processing and food packaging industries.

Aerospace field

Automobile and motorcycle manufacturing

Chemical industry

Marine engineering

Our professional sales team are waiting for your consultation.