Key features and functions:

Energy conversion:

The blades in the turbine arc section convert the kinetic energy of the fluid intomechanical energy through interaction with the fluid. When the fluid passes through the turbine arc,the pressure on the blades and the dynamic pressure cause the turbine to rotate, thereby driving theconnected equipment or generator.

Fluid control:

The blades in the turbine arc are designed to specific shapes and angles to control theflow direction and speed of the fluid. By adjusting the angle of the blades, the performance of the turbinecan be optimized and the energy conversion efficiency improved.

Working environment:

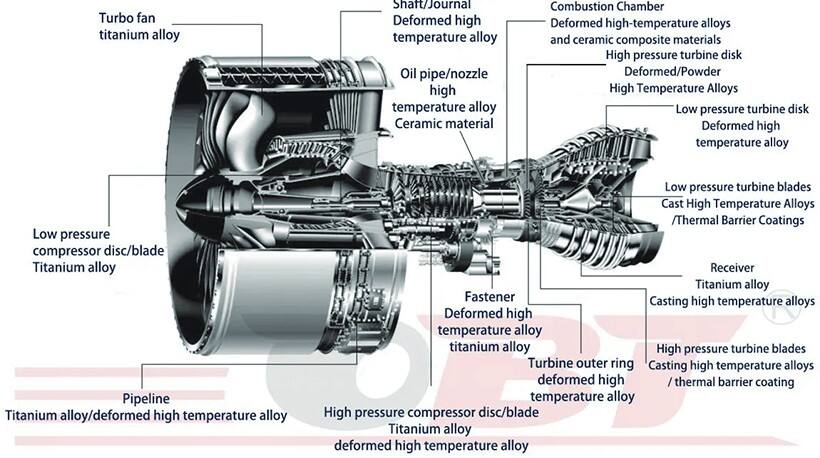

The turbine arc section usually operates in a working environment of hightemperature, high pressure and high speed, so it needs to be made of high temperature resistant materialssuch as high temperature alloys. These materials have good thermal resistance and mechanical strength,allowing them to maintain stable performance under extreme conditions.

Structural design:

The structural design of the turbine arc section needs to consider factors such as fluiddynamics, material mechanics, and thermodynamics. Blade shape, size and layout have a significantimpact on turbine performance and require precise design and optimization.

Cooling system:

Since the turbine arc section is susceptible to thermal stress in high-temperature working environments, a cooling system is usually required to control the temperature and extend the service life of the components. These cooling systems can be internal channels or the injection of external coolingmedia to effectively reduce the operating temperature of the blades.

product

material

Inconel material Hastelloy material Stellite material Titanium material Nimonic Alloy material

Aerospace field:Turbine segment are widely used in aerospace engines, including jet engines,turbofan engines, etc. They carry the turbine blades, which rotate to drive thecompressor, turbine and other related components to provide power tosupport the flight of the aircraft.

Energy industry:In the energy field, turbine segment are used in steam turbines, gas turbines,steam turbines and other equipment in various types of generating units.They convert gas or steam energy into electrical energy for use in powergeneration plants by turning the rotor of a generator.

Industrial field:In the industrial field, turbine segment are used in various types ofturbomachinery equipment, such as compressors, fans, pumps, etc. Theyrealize the compression, transportation or circulation of fluids or gasesthrough rotation and are used for power transmission and energy conversionin industrial production, manufacturing and processing processes.

Industrial field:In the energy extraction field, turbine segment are used in various turbinemachinery equipment, such as oil and gas extraction equipment,hydroelectric power generation equipment, etc. They drive relatedequipment through rotation to improve energy extraction efficiency andproductivity

| Name | Inner Cavity Cooling Channel Coating | External Surface Coating | ||

| Nickel Aluminum Diffusion Coating | MTK-NAI | MTK-WAI | ||

| Aluminum Silicon Diffusion Coating | MTK-NAISi | MTK-JAISi | ||

| Chrome Aluminum Diffusion Coating | MTK-NAICr | MTK-WAICr | ||

| Diamond Aluminum Diffusion Coating | MTK-NAICo | MTK-WAICo | ||

| Platinum Aluminum Diffusion Coating | MTK-WPtAl | |||

| Aluminum Diffusion Coating | MTK-NAITi | MTK-WAITi | ||

| Q Salt Electroplating Platinum | MTK-WPt | |||

| Compressor Inorganic Phosphate Coating | MTK-WAI | |||

| MCrAIY Coating Technology | MTK-RZ | |||

| TBC | MTK-TBC | |||

| CVD Vapor Phase Aluminizing | ||||

| Chromated Aluminum Coating Technology | ||||