Turbine Stator is an important part of the turbine, usually located around the turbine rotating parts (such as turbineblades). Corresponding to the turbine blades, the stator is fixed and its main function is to guide the airflow andconvert the kinetic energy of the airflow through static pressure.

The main functions and characteristics of the turbine stator include:

Guide airflow:The turbine stator guides high-speed airflow along a predetermined path through its specialgeometry and flow channel design. This helps optimize the flow characteristics of the airflowand improve energy conversion efficiency.

Convert kinetic energy:When high-speed airflow passes through the turbine stator, the curved shape and flowchannel design of the stator surface can convert the kinetic energy of the airflow into staticpressure energy. This energy conversion helps increase the pressure of the gas, improvingturbine performance.

Reduce airflow speed:The flow channel design of the turbine stator can reduce the speed of the airflow, so that theairflow speed is reduced when it leaves the turbine, thereby reducing the turbulence loss ofthe airflow and improving the efficiency of the turbine.

Adjust flow:By adjusting the geometry of the turbine stator and the flow channel design, the flow andspeed of the airflow can be controlled, thereby adjusting and optimizing turbine performance.

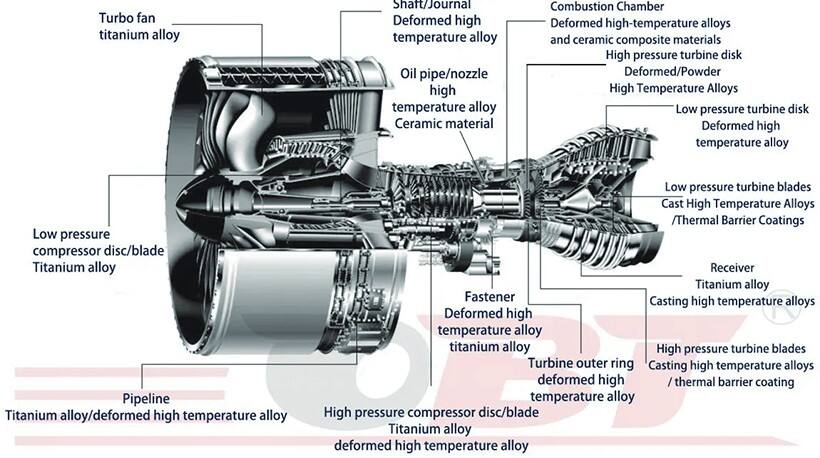

Heat-resistant materials:Turbine stators are usually made of high-temperature alloys or other high-temperatureresistant materials to ensure their stability and durability in high-temperature andhigh-pressure environments.

material

Inconel material Hastelloy material Stellite material Titanium material Nimonic Alloy material

Main Functions

The turbine stator is an essential component in axial-flow turbines, used in various applications such as jet engines, power generation turbines, and turbochargers. The stator consists of a series of stationary vanes or blades that direct the flow of high-energy gases onto the rotating turbine blades. This guidance optimizes the angle and velocity of the gases, enhancing the efficiency and performance of the turbine.

Aerospace field:Turbine stator are widely used in aerospace engines, including jet engines,turbofan engines, etc. They carry the turbine blades, which rotate to drive thecompressor, turbine and other related components to provide power tosupport the flight of the aircraft.

Energy industry:In the energy field, turbine stator are used in steam turbines, gas turbines,steam turbines and other equipment in various types of generating units.They convert gas or steam energy into electrical energy for use in powergeneration plants by turning the rotor of a generator.

Industrial field:In the industrial field, turbine stator are used in various types ofturbomachinery equipment, such as compressors, fans, pumps, etc. Theyrealize the compression, transportation or circulation of fluids or gasesthrough rotation and are used for power transmission and energy conversionin industrial production, manufacturing and processing processes.

Industrial field:In the energy extraction field, turbine stator are used in various turbinemachinery equipment, such as oil and gas extraction equipment,hydroelectric power generation equipment, etc. They drive relatedequipment through rotation to improve energy extraction efficiency andproductivity

Transportation field:Turbine stator are used in turbochargers in automobile engines to improveengine power and fuel efficiency, as well as in turbochargers for transportationvehicles such as trains and ships.

Shipbuilding industry:Turbine stator are used in ship power devices, such as turbochargersand marine turbines, to provide power to drive ships.

Our professional sales team are waiting for your consultation.