Video

Function:

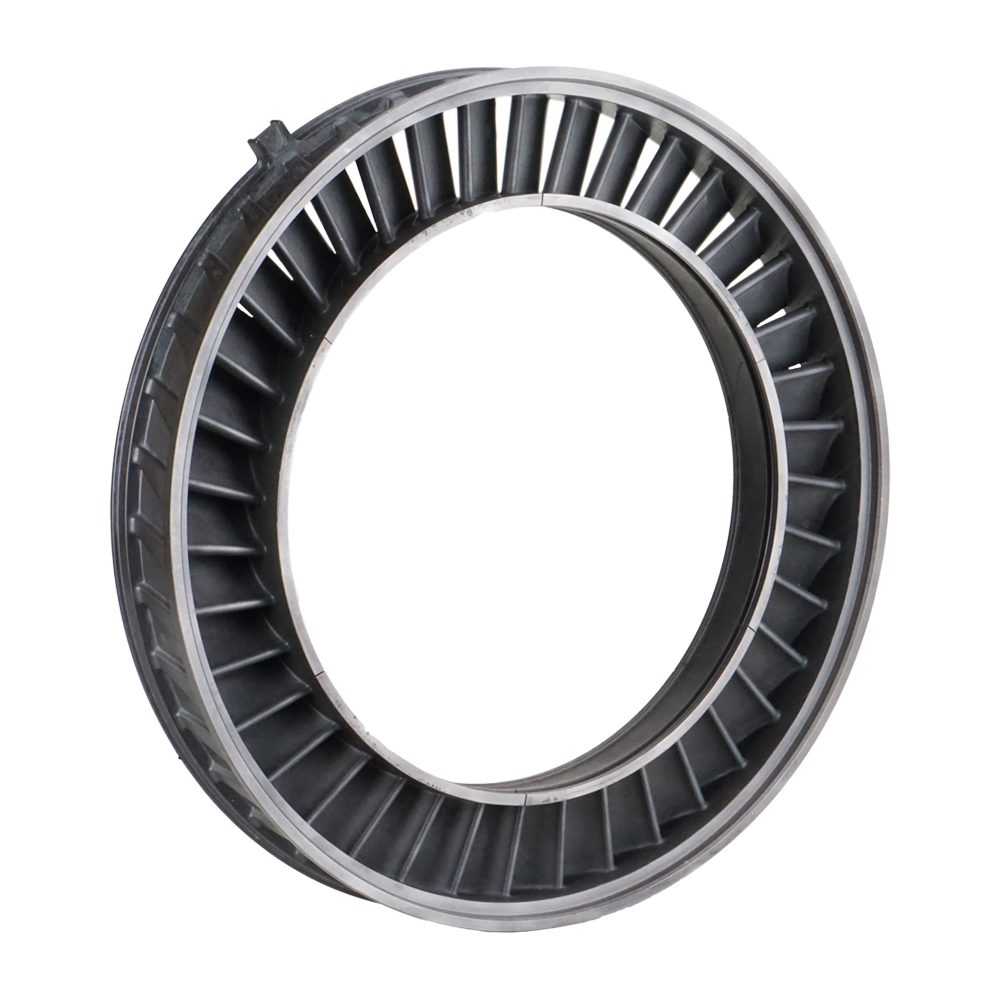

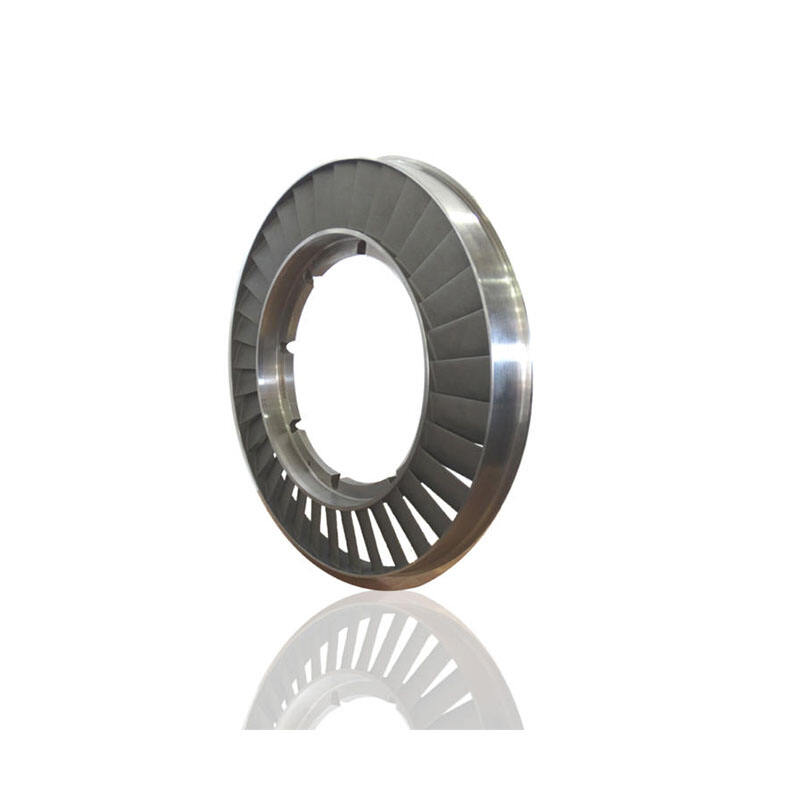

The turbine nozzle ring is located between the combustion chamber and the turbinerotor blades. Its main function is to direct the hot gas flow from the combustionchamber to the turbine blades at the correct angle and speed to maximize energyextraction.

AERODYNAMIC DESIGN:

The nozzle ring is engineered for optimal aerodynamic performance. It shapes andaccelerates the hot gases to the desired speed before they enter the turbine rotor blades.The design may include a series of vanes or nozzles that help control flow direction andvelocity distribution.

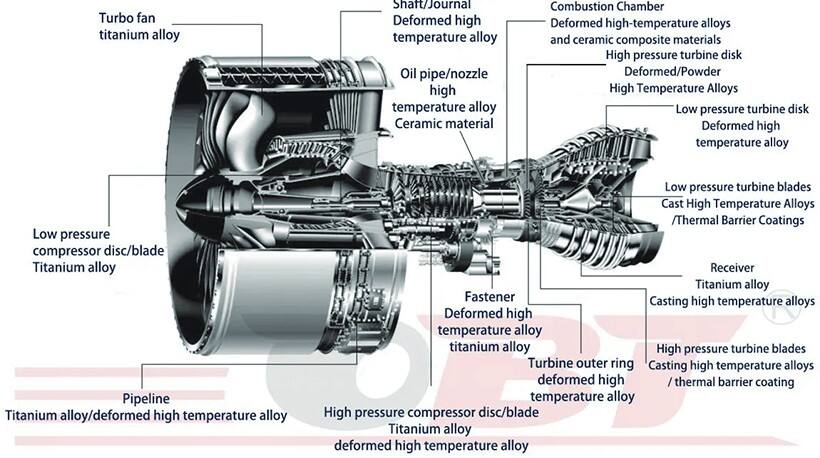

Materials:

Turbine nozzle rings are typically made of high-temperature-resistant materials, suchas nickel-based superalloys or ceramic composites. These materials can withstand thehigh temperatures and mechanical stresses experienced in the turbine section of theengine.

Cooling:

In some high-performance gas turbine engines, the turbine nozzle ring may containinternal cooling channels or external film cooling to protect it from the extreme heatof the combustion gases. This helps maintain the structural integrity and longevity ofthe component. Efficiency and

Performance:

The design and condition of the turbine nozzle ring has a significant impact on theoverall efficiency and performance of the gas turbine engine. Proper aerodynamicdesign and maintenance of the nozzle ring are critical to ensuring optimal energy isobtained from the combustion gases.

material

Inconel material Hastelloy material Stellite material Titanium material Nimonic Alloy material

features

Turbine nozzle rings are designed to guide and control theflow of fluid (such as gas, steam or water) through the turbine blades to achieve optimal power output. It can ensure that thefluid enters the turbine blades at the appropriate speed anddirection to maximize its kinetic energy through the designedaerodynamic characteristics.

Since the nozzle ring is located in the high temperature andhigh pressure part of the gas turbine or steam turbine, it isusually made of high temperature alloy or ceramic compositematerial to ensure its ability to withstand high temperatureand high pressure and ensure long-term stable operation.

The aerodynamic design of the nozzle ring has been preciselyoptimized to ensure optimal hydrodynamic performance.Through proper nozzle shape, angle and layout, the nozzlering can accelerate and spread the fluid to maximize poweroutput efficiency

The nozzle ring usually needs to have excellent wear resistance and corrosion resistance to cope with wear and chemicalcorrosion during long-term high-speed fluid flow. Its surfacemay be specially treated or coated to enhance its surfacehardness and corrosion resistance.

Some nozzle rings may be designed with an internal coolingstructure, which can effectively cool the nozzle ring throughcooling channels or cooling air inlets to reduce its operatingtemperature and extend its service life..

Nozzle rings often undergo a precision manufacturing andassembly process to ensure their dimensional accuracy andaerodynamic performance. The manufacturing process mayinclude processes such as CNC machining, casting orinvestment casting.

application

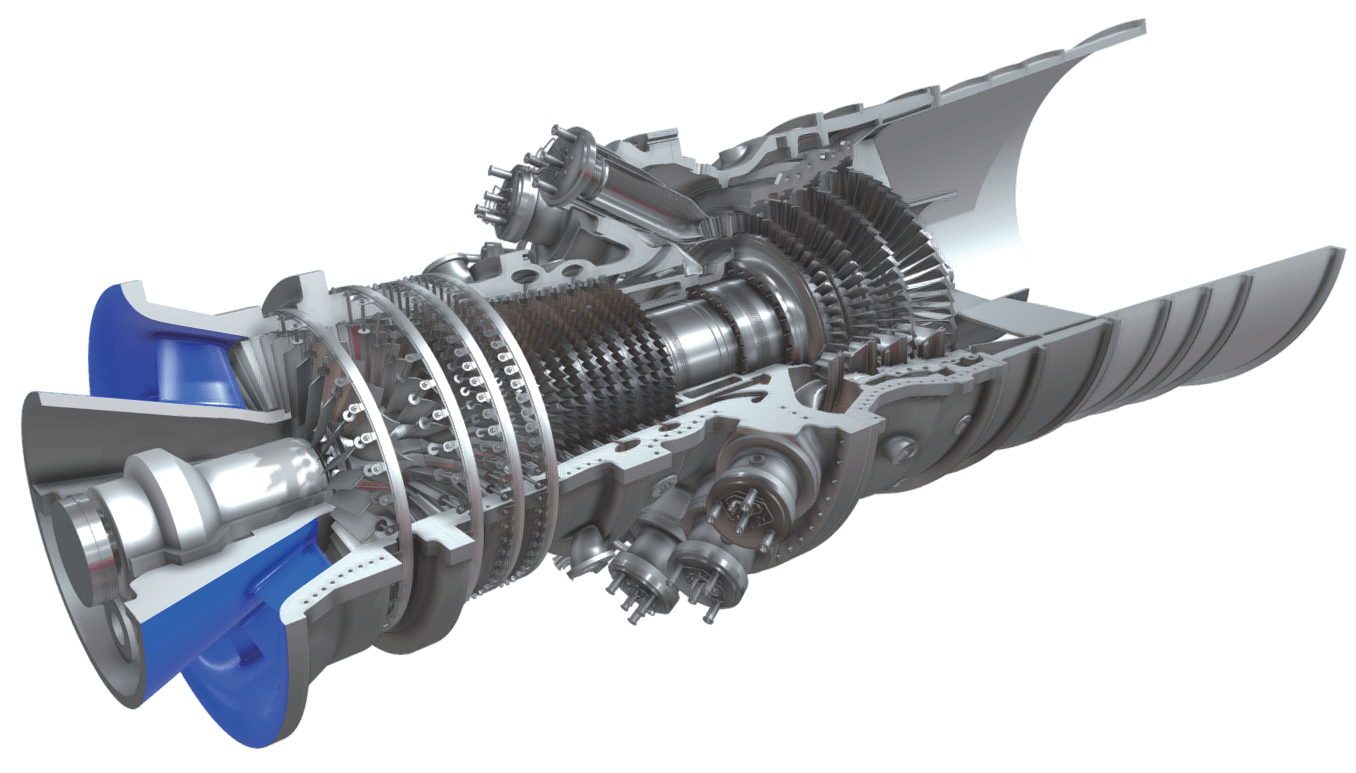

Gas Turbine: In a gas turbine, the turbine nozzle ring is located between the combustionchamber and the turbine rotor blades to guide and control the flow of gas to the turbineblades. The nozzle ring enables the gas flow to enter the turbine blades at the appropriatespeed and angle to achieve maximum energy extraction and efficient power output.These systems are commonly used in areas such as power plants, aerospace engines, andindustrial applications.

Steam turbine: In a steam turbine, the turbine nozzle ring is also locatedbetween the combustion chamber and the turbine rotor blades and playsa role in controlling and guiding the hot gas flow. Steam turbines are usuallyused in power plants and industrial production processes to converthigh-temperature and high-pressure steam energy into rotational power todrive generators to generate electricity or drive mechanical equipment.

| GB | UNS | SEW VDIUV | |

| Incoloy 800 | NS111 | N08800 | W.Nr.1.4876 |

| X10NiCrAlTi3220 | |||

| Incoloy 800H | NS112 | NO8810 | W.Nr.1.4958 |

| X5 NiCrAlTi 31-20 | |||

| Incoloy 800HT | N08811 | W.Nr.1.4959* | |

| X 8 NiCrAlTi 32-21 | |||

| Incoloy 825 | NS142 | N08825 | W.Nr.2.4858 |

| NiCr21Mo | |||

| Inconel 600 | NS312 | N06600 | W.Nr.2.4816 |

| NiCrl 5Fe | |||

| Inconel 601 | NS313 | N06601 | W.Nr.2.4851 |

| NiCr23Fe | |||

| Inconel 625 | NS336 | N06625 | W.Nr.2.4856 |

| NiCr22Mo9Nb | |||

| Inconel 718 | GH4169 | N07718 | W.Nr.2.4668 |

| NiCr19Fe19Nb5Mo3 | |||

| Incoloy 926 | N08926 | W.Nr.1.4529 | |

| X1NiCrMoCu | |||

| Inconel X-750 | GH4145 | N07750 | W.Nr.2.4669 |

| NiCr15Fe7TiAl | |||

| Monel 400 | N04400 | W.Nr.2.4360 | |

| NiCu30Fe | |||

| Hastelloy B | Ns321 | N10001 | |

| Hastelloy B-2 | NS322 | N10665 | W.Nr.2.4617 |

| NiMo28 | |||

| Hastelloy C | NS333 | ||

| Hastelloy C-22 | N06022 | W.Nr.2.4602 | |

| Hastelloy C276 | NS334 | N10276 | W.Nr.2.4819 |

| NiMo16Cr15W | |||

| 254SMO | S31254 | W.Nr.1.4547 | |

| 904L | N08904 | W.Nr.1.4539 | |

| GH1140 | GH1140 | ||

| GH2132 | GH2132 | S66286 | W.Nr.1.4890 |

| GH3030 | GH3030 | ||

| GH3044 | GH3044 | ||

| GH3128 | GH3128 | ||

| Carpenter 20 | NS143 | N08020 | W.Nr.2.4660 |

| NiCr20CuMo | |||

| Alloy31 | N08031 | W.Nr.1.4562 | |

| X1NiCrMoCu32-28-7 | |||

| Invar 36 | K93600 | W.Nr.1.3912 | |

| Ni36 |

Our professional sales team are waiting for your consultation.