Introduction

In the fields of aerospace, energy, and industry, turbine blades are critical components. They not only need to withstand extreme working conditions but also maintain high performance. Therefore, choosing the right materials and manufacturing techniques is essential for turbine blade production. This article will explore how advanced CNC (Computer Numerical Control) machining technology is used to produce high-quality turbine blades and introduce our company's unique advantages in this field.

The Importance and Challenges of Turbine Blades

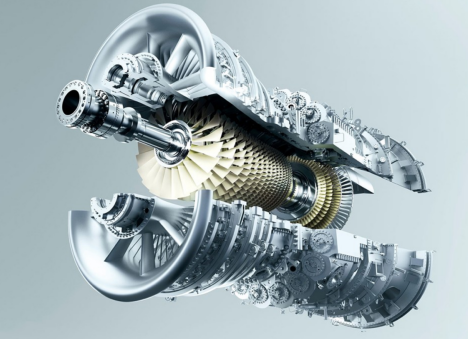

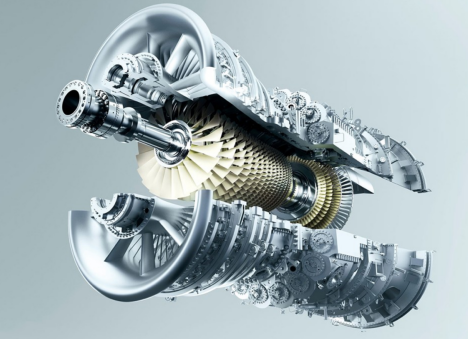

- Function Overview: Turbine blades play a crucial role in converting thermal energy into mechanical energy, which is then used to drive turbines in power plants, aircraft engines, and other industrial applications. These blades are designed to capture the kinetic energy of the flowing gas or steam and convert it into rotational motion.

- Operating Conditions: These components operate under extremely harsh conditions, including high temperatures (often exceeding 1,000°C), high pressures, and high-speed rotation. The blades must be able to endure these conditions without degrading or failing. Additionally, they must resist corrosion, erosion, and fatigue over long periods of operation.

- Design Requirements: To meet these demanding requirements, turbine blades must be made from high-strength, heat-resistant materials such as nickel-based superalloys, titanium alloys, and ceramic matrix composites. The design must also consider aerodynamic efficiency, structural integrity, and the ability to handle dynamic loads. Advanced computational fluid dynamics (CFD) and finite element analysis (FEA) are often used to optimize the blade design before manufacturing.

Application of CNC Machining Technology in Turbine Blade Manufacturing

- CNC Machining Introduction: CNC machining involves using computer-controlled machine tools to remove material from a workpiece to create the desired part. The process is highly automated and can achieve very high precision. Modern CNC machines use multi-axis capabilities, allowing for the creation of complex geometries with high accuracy.

- Advantages Analysis:

- High Precision: CNC machines can achieve tolerances within microns, ensuring that each blade is manufactured to exact specifications. This level of precision is critical for maintaining the aerodynamic performance and structural integrity of the blades.

- Consistency: The use of pre-programmed instructions ensures that every part is identical, maintaining high quality and reliability. This consistency is especially important in mass production, where even small variations can affect overall system performance.

- Complex Shape Handling: CNC machining is particularly well-suited for producing parts with complex geometries, such as the intricate shapes required for efficient aerodynamics. Multi-axis CNC machines can handle curved surfaces, thin walls, and other challenging features.

- Wide Material Compatibility: CNC machines can work with a wide range of materials, including difficult-to-machine alloys and composites. This flexibility allows us to select the most appropriate material for each application, ensuring optimal performance and durability.

- Specific Cases/Examples: For instance, our company uses advanced CAD/CAM software to design and simulate the blade geometry before machining. This allows us to optimize the design for both performance and manufacturability. We also employ multi-axis CNC machines, which can handle the most complex shapes and ensure that the final product meets all design requirements. Our team of experienced engineers works closely with customers to understand their specific needs and tailor the manufacturing process accordingly.

Our Company’s Advantages

- Technological Leadership: We are equipped with state-of-the-art CNC machines and a team of experienced engineers who continuously explore new materials and processes. Our R&D department works closely with leading research institutions to stay at the forefront of technological advancements. We invest in the latest software and hardware to ensure that we can deliver the highest quality products.

- Quality Assurance System: We have implemented a comprehensive quality management system that covers every step of the production process, from raw material selection to final inspection. This includes rigorous testing and validation procedures, such as non-destructive testing (NDT) and mechanical testing, to ensure that each blade we produce meets the highest standards of quality and reliability.

- Customized Services: We understand that each customer has unique needs, and we offer personalized solutions tailored to their specific requirements. Whether it’s a small batch for prototyping or large-scale production, we can deliver. Our flexible manufacturing processes allow us to adapt to different project sizes and timelines, ensuring that we meet our customers’ expectations.

- Quick Response to Market Changes: Our agile manufacturing processes and robust supply chain management allow us to quickly adapt to changes in market demand. We can rapidly scale up or down production to meet our customers’ needs. This responsiveness is particularly valuable in industries where market conditions can change rapidly, such as aerospace and energy.

- Commitment to Sustainable Development: We are committed to environmental sustainability and implement various measures to reduce our carbon footprint. Our facilities use energy-efficient equipment, and we recycle materials whenever possible. We also invest in research to develop more eco-friendly manufacturing processes, such as using renewable energy sources and minimizing waste.

Conclusion

As technology advances and society develops, the demand for high-performance turbine blades will continue to grow. With our advanced CNC machining technology and professional manufacturing expertise, we are confident in providing our customers with superior products and services. In the future, we will continue to increase our investment in R&D, improve our competitiveness, and strive to become one of the world's leading turbine blade manufacturers.

Contact Us

If you are interested in learning more about our turbine blade manufacturing capabilities or would like to discuss a potential project, please do not hesitate to contact us. Our dedicated team is here to answer your questions and provide you with the information you need. You can reach us by phone at [Your Phone Number], by email at [Your Email Address], or through our website at [Your Website URL]. We look forward to the opportunity to work with you and help bring your projects to life.

Hot News

Hot News