Znaš bolje, došao je vreme da si čuo o turbine sa vodenoj pritom? Uređaj koji koristimo mi za proizvodnju struje je poseban tip turbine (vodenog točka). Obično je to jet turbina povezana sa rotacijom kao što je opisano iznad, ali se umesto plina (zraka) koristi voda (na primer iz reke). Razmislj o tome, ova tehnologija kretanja vode bi mogla biti prosleđena kroz neverovatno malu mašinu i korишćena kod kuće ili u školi.

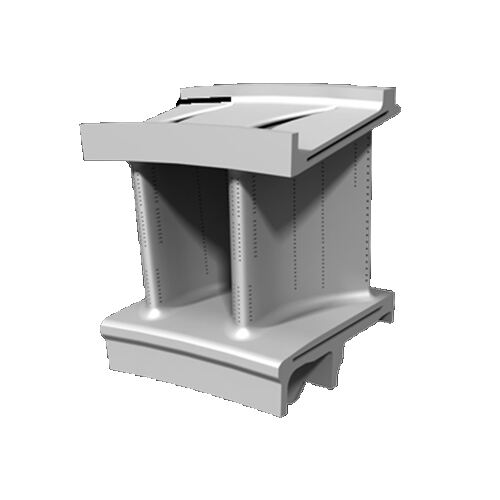

Skup vodilnih lopatica turbine: radi na principu da teče voda preko relativno veće kotača nazvanog turbinom, što uzrokuje njen okretanje. U hidroelektrani (poput ove), voda se sakuplja u rezervoiru za kišni pad ili strujanje koje je usmereno prema veter generatorskom agregatu, koji može biti deo bilo koje turbine i takođe proizvodi električnu energiju. Primeri: Ako su to parelna turbina, impeler u slučaju unutrašnjeg sagorevanja i kompresor za jetske motore, voda je radna tekućina. A vodilne lopasti - to su specifični delovi mašine odakle voda ulazi pre nego što stigne do turbine. Voda se usmerava na turbinu, pomagajući lopaticama turbine da pretvaraju energiju u električnu jednostavnije.

Ove turbine sa vodeničkim livadama imaju efikasnost kojom pretvaraju tok vode u električnu energiju, što povećava isplativost hidroelektrične energije. Voda koja ulazi u turbinu teče brzo i pod pritiskom, pa je to vrlo energična tekućina. Ta snaga se koristi za proizvodnju električne energije koja se dostavlja u naše stambene objekte kao i u poslovne jedinice. Turbine sa vodeničkim livadama razlikuju se po veličini; neke mogu biti velike, a druge male, ovisno o količini električne energije koja je potrebna.

Jedan od najflexibilnijih turbina su Turbine sa vodeničkim livadama. To znači da su dovoljno fleksibilne da se prilagode i obezbede usluge koje ljudi u tim područjima mogu koristiti. Turbine sa vodeničkim livadama mogu biti korišćene za proizvodnju električne energije u planinama, bez ikakvih elektro mreža ili izvora tekuce vode. U gradovima, slično mogu biti korišćene za opsluživanje kuća i poslova čistom energijom. Takođe postoji činjenica da takva turbina - turbine sa vodeničkim livadama, pomoću njih može da dobija elektricnu energiju tokom mnogobrojnih godina bez posebnih popravki i prekida.

Stoga, turbin sa vodenoj pregrade ima mnogo prednosti i predstavlja dobar izbor za proizvodnju električne energije. Najbolje od svega, one ne emituju efekte staklenika. To je jednostavno, ranije je nuklearni otpad bio vrlo toksican, na razliku od običnih elektro postrojenja jer su loši hemikaliji bili otpušteni u zrak. Takođe, nije kako ne koristi štetne prostorne resurse koji se ne obnavljaju kao što su ugljik i nafta. Velika prednost turbina sa vodenoj pregrade jeste proizvodnja velikog količina električne energije uz malo vode. Što znači da moramo da koristimo manje energije negde drugde (procesom koji emituje fosilne goriva). To je veoma korisno za okolinu jer znači da nam treba manje redkom dizel goriva, i sagorevanjem starih tropskih šuma ili naftom za proizvodnju električne energije pomoću turbina sa vodenoj pregrade, čistoća sagorevanja je mnogo bolja od ugljena (svejedno još i on brine za onesrećenje) nego to.

Наша компанija придржава строгих стандарда квалитета да би се осигурао највиши ниво квалитета и pouzdanosti сваког компонента. Контрола квалитета извршава се током целог процеса производње, од набавке сировине до тестовања крајњег производа. Извршавамо такође регуларну проверу квалитета турбине са воденим лоптицама и уравнотеживање да бисмо осигурали константно побољшање квалитета производа. Наши циљеви су да освојимо пузање и дугорочну saradnju нашег клијента пружањем висококвалитетних производа и да постанемо lider u индустрији.

Naša podrška kupcima je širokog spektara i uključuje vodene turbine sa vodimskim upravljačkim letenicama, tehničku podršku i usluge posle prodaje kako bismo osigurali da naši klijenti dobijaju najbolje iskustvo moguće. Naš tim stručnjaka će proceniti zahteve klijenta i ponuditi odgovarajuće rešenja proizvoda i savete. Pružamo tehničku podršku počevši od izbora proizvoda do instalacije i stvaranja u pogon. To osigurava da naši klijenti mogu koristiti naše proizvode bez bilo kakvih problema. Imamo dobro razvijeni proces posle prodaje koji nam omogućava brzo reagovanje na probleme i potrebe kupaca i pružanje efikasnih i brzih rešenja. Određeni smo da razvijemo dugotrajne odnose sa našim klijentima i da osvojimo njihovo poverenje i odnos preko ponude visokokvalitetnih usluga.

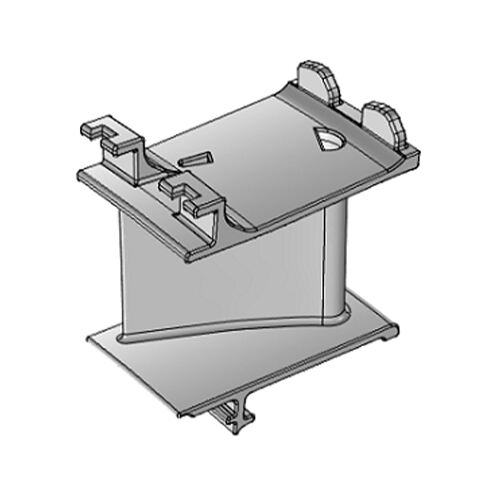

Naša kompanija ima mogućnost da proizvede vrlo tačne i konzistentne komponente turbine koristeći lisaju, forge i CNC vodeni van turbine. Lisajni proces nam omogućava da proizvodimo delove sa složenim oblicima i visokom snagom, dok forge proces daje delovima bolje mehaničke osobine i duže trajanje. CNC mašinska tehnologija, s druge strane, osigurava izuzetno visoku razinu preciznosti i konzistencije u svakoj komponenti, čime se smanjuje rizik od grešaka i nekvalitetnih proizvoda. Naš vешten tehnički tim je uvijek trudio da poboljša tehnološku inovaciju i unapređenje procesa kako bi se osiguralo da naši proizvodi budu na vrhu tehnologije u ovom sektoru. Posvećeni smo ispunjavanju potreba naših klijenata za visoko performantnim turbinama kroz stalno tehnološko napredovanje.

Naša kompanija pruža specifične usluge koje mogu proizvoditi dijelove turbine od niza visokotemperaturnih metala da bi se ispunile potrebe kupaca. Ako je to određena oblika, veličine ili zahtev za performansom, možemo ga ispuniti koristeći naš fleksibilni proces proizvodnje i najnoviju tehnologiju procesa. Držimo se u bliskom kontaktu sa našim klijentima kako bismo shvatali njihove individualne zahteve i scenarije, i pružamo im stručnu tehničku savetovanja i rešenja. Imamo širok raspon materijala i mogućnosti obrade da bi se ispuniše jedinstvene potrebe raznih industrija i primena. Naši klijenti mogu poboljšati svoju vodilicu turbine pružanjem specifičnih usluga koje maksimiziraju performanse i smanjuju troškove.