In turbomachinery systems, high-temperature alloy springs have many important applications, mainly including the following aspects:

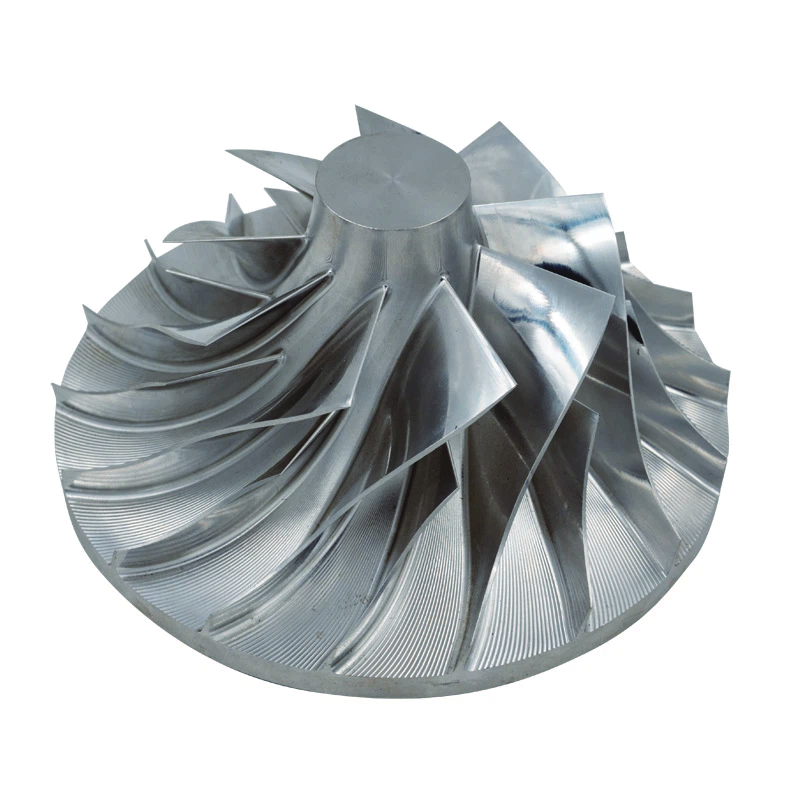

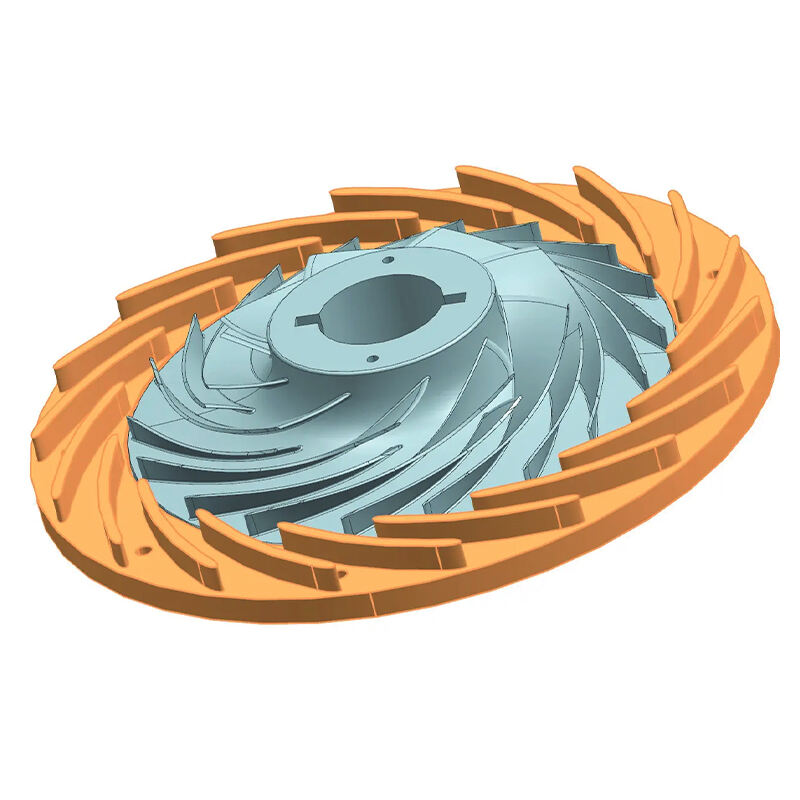

Turbine blade positioning and adjustment: Turbine blades in turbomachinery systems usually need to work in high-temperature and high-speed airflow while maintaining accurate position and angle to ensure efficient operation of the engine. High-temperature alloy springs are used in the positioning and adjustment mechanism of turbine blades to provide stable support and adjustment force to ensure the correct position and attitude of the blades during work.

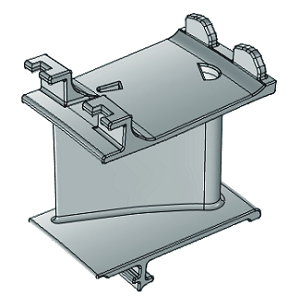

Seals and Vibration Control: Seals and vibration control devices in turbomachinery systems also often operate in high-temperature environments. High-temperature alloy springs can be used for elastic sealing of seals and buffering and shock absorption of vibration control devices, providing reliable sealing performance and vibration control effects.

Gas turbine control valve: In a gas turbine, the control valve is used to adjust the flow and pressure of the gas inlet and outlet to control the output power and operating status of the engine. High-temperature alloy springs are used in spring-loaded devices that control valves to ensure stable operation and accurate control of the valve.

Moving parts of the combustion chamber and exhaust system: In the combustion chamber and exhaust system of the engine, some moving parts such as nozzles, valves, etc. also need to use springs to provide elastic support and control force. High-temperature alloy springs can be used in the spring-loaded devices of these moving parts to ensure reliable operation in high-temperature environments.

product

turbine wheel

turbine blade

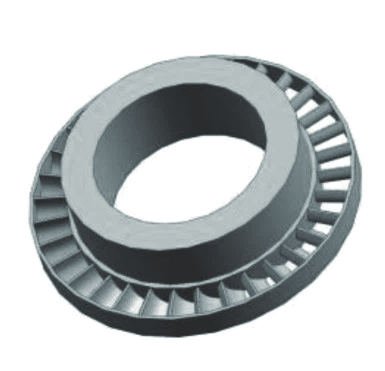

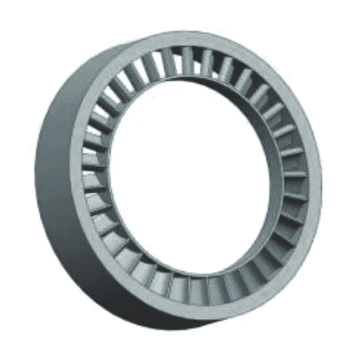

nozzle ring

compressor blade

guide vanes

diffuser

Segment

Turbine Rotor

Turbine Stator

Titanium sheet

Titanium pipe

Titanium rod

Titanium bolt and nut

Titanium Fasteners

Titanium wire

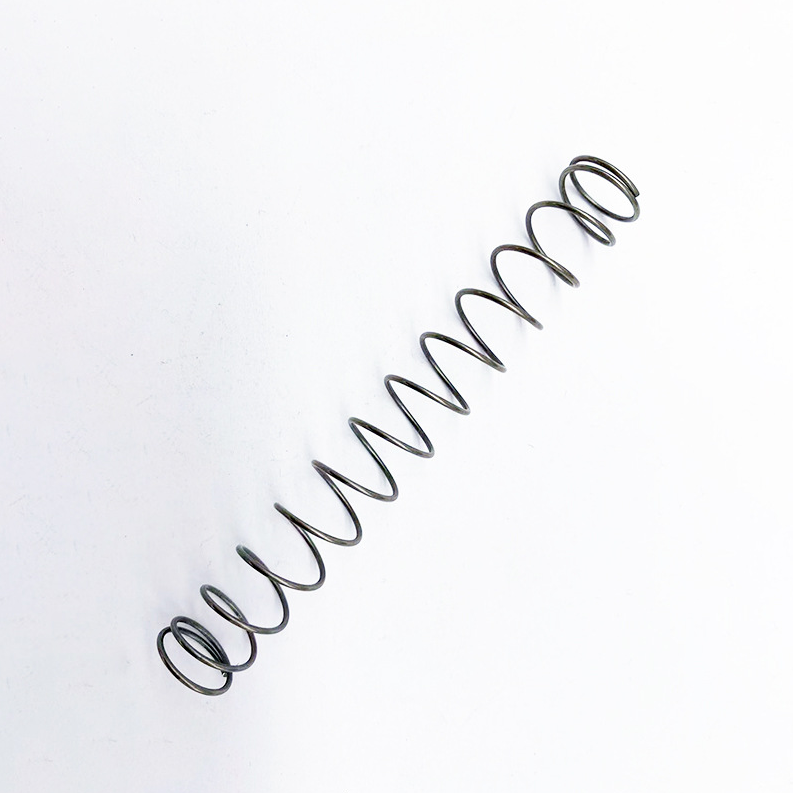

spring

According to drawings or samples

The use scope of high-temperature alloy springs mainly covers various application scenarios that require working in high-temperature environments. The following are some common areas of use of high-temperature alloy springs:

Aerospace: In the aerospace field, equipment such as aircraft engines and spacecraft engines need to work in high-temperature environments. High-temperature alloy springs are used in control valves, valves, actuators and other components to ensure stability and reliability under high-temperature conditions.

Energy field: Some equipment in the energy field, such as gas turbines, turbine generators, nuclear power plants, etc., need to operate in high temperature environments. High-temperature alloy springs are used in control valves, regulators, valves and other components to ensure accuracy and reliability in high-temperature working environments.

Petrochemical Industry: In the petrochemical industry, equipment such as oil refining units, chemical reactors, and high-temperature pipelines require high-temperature-resistant springs to support and control. High-temperature alloy springs can be used in control valves, isolation valves, blowdown valves and other components to cope with high temperatures and corrosive media.

Automotive industry: Turbochargers, exhaust systems and other components of automobile engines also need to work in high-temperature environments. High-temperature alloy springs are used in components such as variable geometry turbines and exhaust valves that control turbochargers to ensure reliability and performance in high-temperature environments.

Heat treatment equipment: In the process of metal processing and heat treatment, high-temperature alloy springs are used to control furnace doors, furnace covers, conveying devices and other components to support and control the operation of heating furnaces, annealing furnaces, quenching furnaces and other equipment.

High-temperature alloy spring is a kind of spring specially designed to work in high-temperature environment, usually made of high-temperature alloy material. These springs play an important role in applications that require operation at high temperatures, high pressures, or in highly corrosive environments.

Features

Material characteristics: High-temperature alloy springs are usually made of special alloy materials such as nickel-based alloys, titanium alloys, and molybdenum alloys. These materials have good high temperature resistance, corrosion resistance and oxidation resistance, and can maintain stable performance in extreme working environments.

High temperature resistance: High-temperature alloy springs can work in high-temperature environments for a long time without failure, and can usually withstand temperatures of hundreds of degrees Celsius, even as high as over 1,000 degrees Celsius.

Spring performance: High-temperature alloy springs have good elasticity and resilience and can maintain stable spring characteristics in high-temperature environments, ensuring their accuracy and reliability during work.

Anti-oxidation properties: These spring materials have excellent anti-oxidation properties and can be used in high temperature environments for a long time without failure due to oxidation.

| Titanium Alloy | Excellent strength and corrosion resistance, as well as low density, are commonly used in high-performance applications in fields such as aerospace and medical devices. |

| Aluminum Alloy | Springs are lightweight and have good corrosion resistance, and are commonly used in applications that require lightweight design, such as aerospace and automotive industries. |

| High-Temperature Alloy | Good high-temperature resistance, usually used for applications in high-temperature environments, such as gas turbines and aviation engines. |

| Iron-Nickel Alloy | Having good magnetism and elasticity, it is commonly used in applications that require magnetism, such as electric motors and sensors. |

| Nickel-Titanium Alloy | The characteristics of shape memory and superelasticity are commonly used in fields such as medical devices, eyeglass frames, and automotive valves. |

material

Inconel material Hastelloy material Stellite material Titanium material Nimonic Alloy material

Our professional sales team are waiting for your consultation.