Home / PRODUCTS / Turbine Accessories / Rotor

The gas turbine rotor, also known as the turbine rotor or turbine wheel, is a key component of the gas turbine engine.It is responsible for extracting energy from the high-speed airflow generated by the combustion process and convertingit into rotating mechanical energy to drive the turbine shaft and ultimately the generator or compressor.

The main features of gas turbine rotors include:

High Strength:

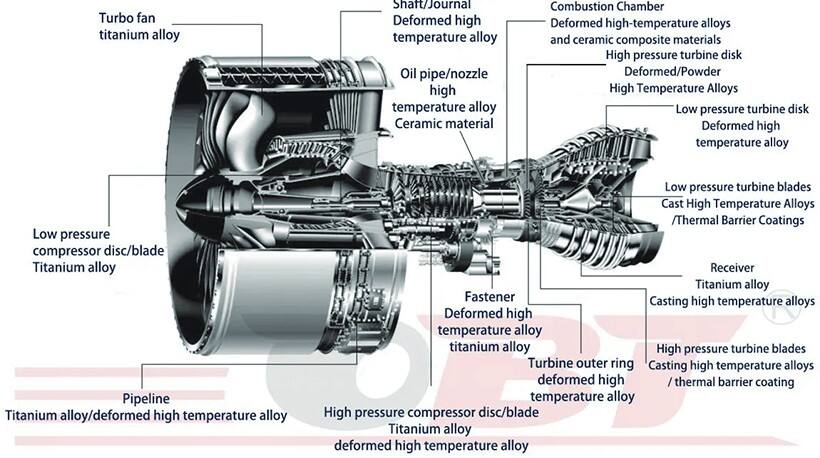

Gas turbine rotors are designed to withstand the high mechanical loads and temperaturesencountered in the turbine environment. They are made from high-strength andhigh-temperature-resistant materials to ensure reliable and long-lasting performance.

Aerodynamic efficiency:

The rotor blades are engineered to maximize aerodynamic efficiency and extract energyfrom the airflow. This involves optimizing blade shape, angle and spacing to minimizelosses and maximize power output.

Balanced:

Gas turbine rotors undergo a precise balancing process to ensure smooth operationand minimize vibration. Imbalance can cause excessive wear, reduced efficiency, and evencatastrophic failure, so careful balancing is critical to reliable turbine operation.

Durability:

Gas turbine rotors undergo rigorous testing and inspection to ensure compliancewith strict quality and safety standards. This includes non-destructive testing methods suchas ultrasonic testing and magnetic particle testing to detect any flaws or imperfections thatcould compromise performance or integrity

According to drawings or samples

material

Inconel material Hastelloy material Stellite material Titanium material Nimonic Alloy material

Aerospace field:Turbine rotor are widely used in aerospace engines, including jet engines,turbofan engines, etc. They carry the turbine blades, which rotate to drive thecompressor, turbine and other related components to provide power tosupport the flight of the aircraft.

Energy industry:In the energy field, turbine rotor are used in steam turbines, gas turbines,steam turbines and other equipment in various types of generating units.They convert gas or steam energy into electrical energy for use in powergeneration plants by turning the rotor of a generator.

Industrial field:In the industrial field, turbine rotor are used in various types ofturbomachinery equipment, such as compressors, fans, pumps, etc. Theyrealize the compression, transportation or circulation of fluids or gasesthrough rotation and are used for power transmission and energy conversionin industrial production, manufacturing and processing processes.

Industrial field:In the energy extraction field, turbine rotor are used in various turbinemachinery equipment, such as oil and gas extraction equipment,hydroelectric power generation equipment, etc. They drive relatedequipment through rotation to improve energy extraction efficiency andproductivity

Transportation field:Turbine rotor are used in turbochargers in automobile engines to improveengine power and fuel efficiency, as well as in turbochargers for transportationvehicles such as trains and ships.

Shipbuilding industry:Turbine rotor are used in ship power devices, such as turbochargersand marine turbines, to provide power to drive ships.

| material | Inconel600,Inconel625,Inconel718,Inconel X-750,Monel 400,Monel K500Hastelloy G-30,Hastelloy X,Hastelloy B-2,Hastelloy C-22,Hastelloy C-276GH4169,GH4145,GH3030,GH2136,GH5188 |

| application | Industrial fans, wind turbines, shipbuilding industry, thermal power plants, nuclear power plants, jet engines, turbojet engines |

| Features | High temperature resistanceAntioxidantCorrosion resistanceThermal fatigue performancegood mechanical propertiesWear resistance |

| Applicable Model | SST-040,SST-060,SST-110,SGT-100,SGT-200,SGT-400GE Frame 5,GE Frame 6,GE Frame 7,GE9X,GE LM2500,GE LM6000MS3002,MS5001NT,MS5001STD,MS5001,MS5002,MS6001,MS7001,MS9001,MS9002 |

Our professional sales team are waiting for your consultation.