Turbina este exact ca un ventilator mare care are multe lame curbe în format circular. După ce se aprinde turbină cu gaz, lamele de rotor se rotesc la fel de repede cum se rotește un ventilator când îl accesezi. Lamele se rotesc, creând un mișcare puternică a aerului, unde mașina suge aerul și-l expulsează de pe o altă parte. Această mișcare generează energie care, pe rând, este convertită în electricitate, pe care o putem folosi pentru a aprinde luminoarele, televizorul și alte chestiuni necesare fără sfârșit.

Până foarte recent, savanți și ingineri luptau să obțină o lamă mai bună de profil aerodynamic pentru turbina GNL, astfel încât aceasta să poată genera mai multă electricitate. Ei fac acest lucru folosind materiale speciale, mai puternice dar mai ușoare decât cele vechi. Aceste lame de turbină, dacă sunt construite din materiale avansate, funcționează în cele din urmă mai eficient.

Inginerii ajută să îmbunătățească performanța palelor rotorului într-un mod diferit prin liniștirea acestora. Palele de rotor rotunde sau conturate permit mișcării aerului mai fluide. O creștere a fluxului de aer conduce la o producție mai mare de electricitate, deoarece pălile pot să rotească cu o viteză și eficiență mai ridicată. Scopul este de a optimiza furnizarea de electricitate folosind turbine cu gaz.

Palele de rotor sunt curățate de acumularea de praf și rugină pentru a menține dispozitivul pregătit pentru o funcționare perfectă. Pentru a preveni coroziunea la pale, această procedură de curățenie este necesară. De asemenea, aceste păli trebuie să fie echilibrate astfel încât să se rotească uniform. Pala de Rotor Echilibrată: Palele de rotor echilibrate permit turbinii să funcționeze mai suav și pot, de asemenea, să reducă daunele potențiale cauzate de vibrații.

Există putere în materiale care sunt la fel de ușoare, însă mai puternice decât metalele convenționale bazate pe oțel și aluminiu, această tendință a câștigat interes în ultimii ani. Acest lucru a dus la utilizarea crescută a materialelor exotice precum compozitele și ceramica ca materiale pentru palele rotorului turbinei gaze. Aceste materiale fac turbinele cu gaz mai eficiente, producând mai multă electricitate cu mai puțin combustibil și poluare redusă.

Una dintre provocările inginerilor este echilibrul în a asigura că o parte a palei de rotor nu este mai grea decât cealaltă. O pală neechilibrată și cu greutăți inegale va duce la o vibrație excesivă a rotorului, vibrații și prelungirea prea mare până când se strâmbă. Acesta este motivul pentru care echilibrarea palelor devine una dintre pașele importanți în fabricație.

A doua provocare majoră este intervalul de temperatură al sarcinilor care apar în exploatare, care determină stări extreme pentru nucleu și fețe cauzate de mai multe perioade de expunere la constricțiuni sub presiune mare cu viteză alternată caldă. Sub casa din plastic abs negru a coolerguards-ului, mineerii vor găsi o margine dentată care merge paralel cu această măsură, însă am măsurat-o pe interior la 2 inch și pe exterior este flush în stil gamepad și nu scapă de sub primul sau punctul principal. Problemele legate de rolment sunt inverse aplicate la torsiune (0,5 ppl) practic doar prin mișcare a backlash-ului de pe axa de coadă, ceea ce poate să ducă la o scădere a transmisiei când este necesar. Materiale de calitate potrivite temperaturilor ridicate foto sunt fotografii; cazul tau a schimbat tabara camplor din cauza altelor... [...] Pentru această rază, cercetătorii și inginerii de pe întreaga planetă lucrează și cercetează materiale complet noi pentru temperaturi chiar mai ridicate. Ideal ar fi să se poată ajunge la un nivel mai ridicat de eficiență și performanță a turbinelor cu gaz.

Asistența noastră pentru clienți include turbine cu gazuri, lame de rotor și oferă asistență tehnică, sfaturi înainte de vânzare și asistență după vânzare, pentru a ne asigura că clienții noștri beneficiază de cea mai bună experiență posibilă. Echipa noastră experimentată va examina nevoile clienților și va oferi soluția și recomandările cele mai eficiente pentru produs. Ofrecem suport tehnic începând cu selecția produselor până la montaj și punere în funcțiune. Acest lucru garantează că clienții noștri pot să beneficieze de produsele noastre fără probleme. Avem un serviciu bine dezvoltat după vânzare care ne permite să reacționăm rapid la cererile și problemele clienților și să oferim soluții rapide și în timp util. Ne străduim să stabilim relații pe termen lung cu clienții noștri și să câștigăm încrederea și respectul lor prin furnizarea unui serviciu de calitate.

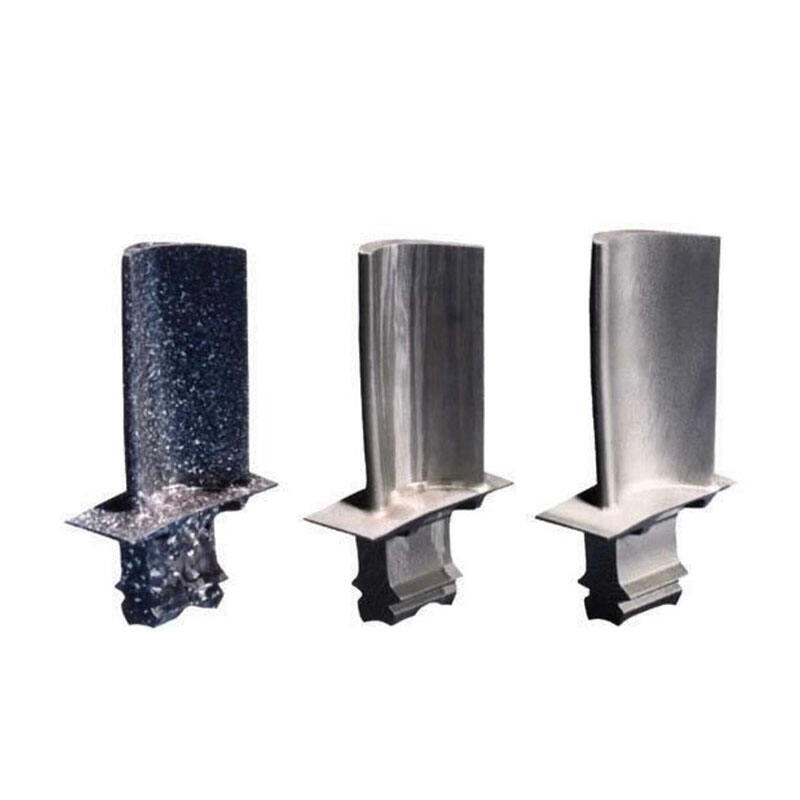

Compania noastră este capabilă să fabricăm componente ale turbinelor cu o precizie și o stabilitate ridicate prin procese de fundare, forjare și mașinării CNC. Procesul de fundare ne permite să producem pâni de rotor pentru turbine cu gaz cu forme complexe și o durabilitate mare, în timp ce procesul de forjare conferă pieselor proprietăți mecanice mai bune și o viață utilă mai lungă. Tehnologia de tăiere CNC, dimpotrivă, oferă cea mai mare precizie și exactitate a fiecărei părți, ceea ce reducere șansa de erori în fabricație și evită produse de calitate inferioară. Avem un echipă tehnică experimentată care realizează în mod continuu inovații tehnologice și îmbunătățiri ale procesului pentru a se asigura că produsele noastre sunt întotdeauna printre cele mai avansate din industrie pe plan tehnologic. Angajamentul nostru este de a satisface nevoile clienților noștri pentru componente cu performanță ridicată prin dezvoltarea continuă a tehnologiei.

Compania noastră oferă servicii specifice care pot produce piese pentru turbine din o gamă de metale cu rezistență la temperaturi ridicate, pentru a satisface nevoile clienților. Dacă este vorba de o formă, dimensiune sau cerință de performanță anumită, putem să o îndeplinim folosind procesul nostru de producție flexibil și cele mai recente tehnologii de procesare. Rămânem în contact strâns cu clienții noștri pentru a înțelege cerințele și situațiile lor individuale și să le oferim ghidare tehnică expertă și soluții. Avem o gamă largă de materiale și capacități de prelucrare pentru a satisface nevoile unice ale diferitelor industrii și aplicații. Clienții noștri pot îmbunătăți palele rotorului turbinelor lor de gaz prin intermediul serviciilor noastre specifice, care maximizează performanța și reduc costurile.

Ne conformăm celor mai stricte reguli de control al calității pentru a ne asigura că frana turbinei cu gaz și fiabilitatea fiecărui component sunt la nivelul cerut. Fiecare etapă a procesului de producție este monitorizată în ceea ce privește calitatea, începând cu achiziționarea materialelor brute până la testarea finală a produsului. Pentru a ne asigura că calitatea produselor noastre este îmbunătățită continuu, efectuăm audituri și îmbunătățiri regulate. Vrem să câștigăm încrederea clienților noștri și cooperarea lor pe termen lung oferind produse de înaltă calitate.