Men, før vi går inn på hvordan nozzle-ringene fungerer, la oss først få litt innsikt i motorene. Biler motore består av luft og brøyte Og når det dannes, gir det et stort knall som fungerer som en raket-boost for bilen til å kjøre fremover. Den gir en større knall i motoren, og dermed.. mer fart kan oppnås av bilen vår hvis vi får enda mer luft inn i motoren! Her kommer turbolen i hånden for å ta fordel på det for bedre bruk.

Hvordan det fungerer: En turboluter fanger opp gassen som kommer ut av en motors forbreningsprosess. Den fanger disse avføringsgasene og dreier en vifte. Denne viften har en viktig funksjon ved å trekke mer luft inn i motoren fra utsiden. Å levere for mye luft på denne måten kalles tvungen induksjon, og er hva som lar motoren produsere den krevede effekten for en raskere reisehastighet.

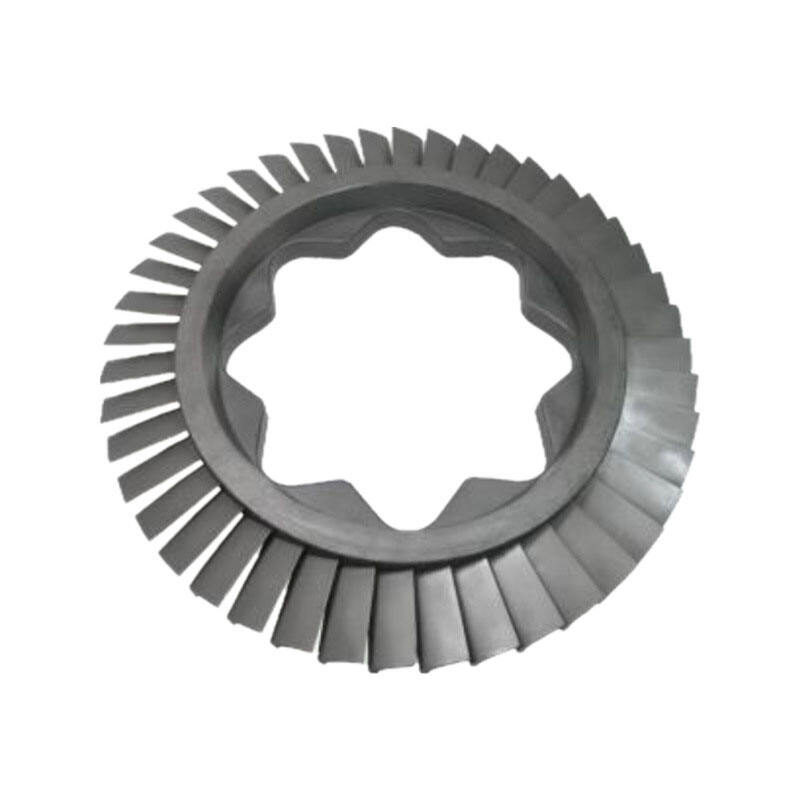

Dusjringene på en turbolader kan virke ganske enkle, men hvordan de faktisk fungerer er ganske komplisert grunnet antall viktige komponenter som AKSELSKJER og aksesteknologi. Først og fremst er klaffene en del av dette. Dette er de lille vingene du ser stikke ut fra dusjringen. Dette er kritisk for den normale drifta av turbouppsettet, siden det raske flytende luft som kommer ut av en kjørende ventilator må ha et sted å gå.

Den andre delen av dette er den hydrauliske nullspalten, også kjent som mellomrommet mellom klaffene og huset på dusjringen. Dette er viktig siden det påvirker hvor mye luft dusjringen kan strømme. Men, hvis spalten er for tett (med andre ord, det er ikke nok luft til å strømme), kan dette hindre ytelsen. Omvendt, hvis spalten er for stor, vil det være mer luftstrøm enn nødvendig, noe som kan redusere effektiviteten og opprette problemer.

Vedlikehold av ditt spruterring settet uttrykt, er det flere viktige vedlikeholdssteg som du må gjøre for å holde spruteringsanlegget i god stand. For det første er det avgjørende at motoreoljet ditt ikke blir forurenset på noen måte. Turboen bruker olje for å forebygge celleskader innenfor motoren, så hvis den blir for smalt eller gammel over tid, kan den blokkere spruterringen. Hvis spruterringen blir blokkert, faller effektiviteten kraftig, så sørg for at du utfører regelmessige oljeskifter.

Hvis du overveier å bytte ut bilens turbospruterring, bør du ta hensyn til noen ting. Tanken om størrelsen med hensyn til spruterringen! I vårt tilfelle betyr en større spruterring mer fortrykk, som igjen betyr mer kraft! Dette sagt, øker det også belastningen på motoren. En mindre spruterring kan være mer effektiv, men kan muligens ikke ha samme kraftoutput.

Deretter er det nozzle-ring-stilen, til slutt. Det finnes nozzle-ringer som har blitt utviklet på grunn av effektivitet, og andre som har til hensikt å gi deg noe alvorlig hestekraft. Når du velger en nozzle-ring-størrelse, ønsker du å sørg for at den er i stand til å gi boosten som kjøretøyet ditt krever basert på hvor mye kraft og ytelsesgeving som trengs.

Vår fullstendige kundeservicepakke omfatter teknisk assistanse, forsalgsråd og etter-salgsassistanse for å sikre at våre kunder får den beste opplevelsen mulig. Ved forsalg vil vårt ekspertteam forstå kundens behov i detalj og gi de mest passende produktforslag og løsninger. Vi tilbyr teknisk assistanse fra produktvalg gjennom installasjon og innsetting. Dette garanterer at våre kunder kan bruke våre produkter uten problemer. Vi har et godt utviklet etter-salgsystem som lar oss reagere raskt på kundenes spørsmål og problemstillinger og gi effektive og hurtige løsninger. Målet vårt er å opprettholde lange varighetsforhold med våre kunder og vinne deres tillit og tilfredshet ved å tilby kvalitetservice.

Vår bedrift tilbyr spesifikke tjenester som kan produsere turbinekomponenter fra en rekke høytemperatursmetaller for å møte kundenes behov. Uansett om det er et bestemt form, størrelse eller ytelseskrev, så klarer vi å oppfylle det ved hjelp av vår fleksible produksjonsprosess og den nyeste prosessteknologien. Vi holder nært kontakt med våre kunder for å forstå deres individuelle krav og situasjoner, og gir dem ekspert teknisk veiledning og løsninger. Vi har et bredt utvalg av materialer og prosesskapasiteter for å møte de unike behovene i ulike industrier og anvendelser. Våre kunder kan forbedre sin turbooppladeringsdusjring ved å tilby spesifikke tjenester som maksimerer ytelsen og reduserer kostnadene.

Vi kan lage turbinekomponenter med høy nøyaktighet og konsistens ved hjelp av CNC-forming, maskinering og formverk prosesser. Forming lar oss lage deler med turbooppladeresprøyte ring, sterke og varige. Formverk tilbyr deler som er mer varige og har bedre mekaniske egenskaper. CNC-maskinering er derimot ekstremt nøyaktig og konsistent for hver eneste del. Dette fjerner feil og produkter av dårlig kvalitet. Vår erfarene tekniske team forsker kontinuerlig etter teknologiske fremgang og prosessoptimaliseringer for å holde våre produkter på toppen av bransjens teknologi. Vi er dedikerte til å møte kravene fra våre kunder på høy ytelsesturbinekomponenter ved å drive med kontinuerlig teknologisk utvikling.

Vi holder oss til de strengeste retningslinjene for kvalitetskontroll for å sikre påliteligheten på hver komponent av turboladerens sprengeventil. Hver trinn i produksjonsprosessen overvåkes med hensyn til kvalitet, fra innkjøp av råmaterialer til den endelige produkttesten. For å sikre at kvaliteten på våre produkter forbedres kontinuerlig, gjennomfører vi regelmessige revisjoner og forbedringer. Vi ønsker å vinne våre kunders tillit og deres langtidsamarbeid ved å levere høykvalitetsprodukter.