Stellite kobalt-basd legingen bestaan uit complexe carbiden in de legingsmatrix. Ze zijn bestand tegen slijtage, erosie en corrosie en behouden deze eigenschappen bij hoge temperaturen. Hun uitstekende slijtagebestendigheid wordt voornamelijk toegeschreven aan de unieke intrinsieke eigenschappen van de harde carbide fase die verspreid is in de CoCr legingsmatrix.

Stellite 21 (vroeger Stellite 8) ontwikkeld

Het verscheen in de mid-1930s als een corrosiebestendige CoCr legering en vond snel toepassing als een biocompatible heupimplantatie en protheselegering. Veel legeringen die momenteel worden gebruikt in medische toepassingen zijn variaties van de oorspronkelijke Stellite 21 samenstelling. Het was ook een van de eerste hittebestendige legeringen die werden geprobeerd voor gebruik in straalvliegtuigmotoren.

Stellite 21 bestaat uit een CoCrMo legeringsmatrix met verspreide harde carbiden, die de legering versterken en de hardheid verhogen, maar ook ductiliteit verminderen. Het type, de vorm, de grootte en de distributie van de carbiden worden sterk beïnvloed

Vanwege de verwerkingsgeschiedenis van het legering zijn de mechanische eigenschappen van Stellite 21 sterk afhankelijk van de productieroute en eventuele naderende hittebehandeling.

Vanwege het lage carbide-volumepercentage domineert de kobaltgebaseerde legermatrix de slijtage- en corrosieeigenschappen. Stellite 21 biedt uitstekende weerstand tegen cavitering, slijtage en metaal-op-metaal glijderslijtage, maar wordt niet aanbevolen voor ernstige harde deeltjes slijtage. Tijdens slijtage en zelfs tijdens bewerking hardt het oppervlak aanzienlijk en is het belangrijk om de juiste bewerkingsgereedschappen en technieken te gebruiken om de beste resultaten te behalen.

Stellite 21 biedt uitstekende weerstand tegen thermische en mechanische schokken. De optimale hoogtemperatuursterkte wordt bereikt door oplossingshittebehandeling bij 1200–1240C (2190–2265F), gevolgd door quenching en oudering in de temperatuurbereik 700–1150C (1290–2100F).

Stellite 21 kan worden gegoten, poedermetaaltechnisch verwerkt of gebruikt als een weld hardfacing. Aanbevolen voor toepassingen met holing, slijtage, corrosie en/of hoge temperaturen, zoals petrochemische en energieproductie kleppen. Door zijn goede impactweerstand wordt het veel gebruikt bij de vervaardiging van smeed- of warmstempelschuiten. Oxyacetylenweldmethode wordt niet aanbevolen voor deze legering.

product

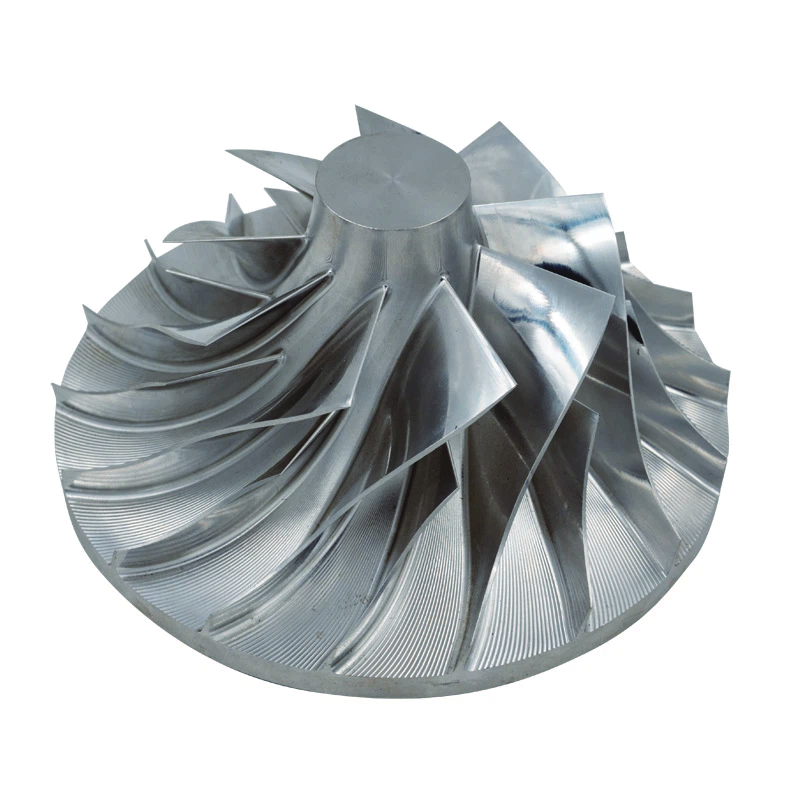

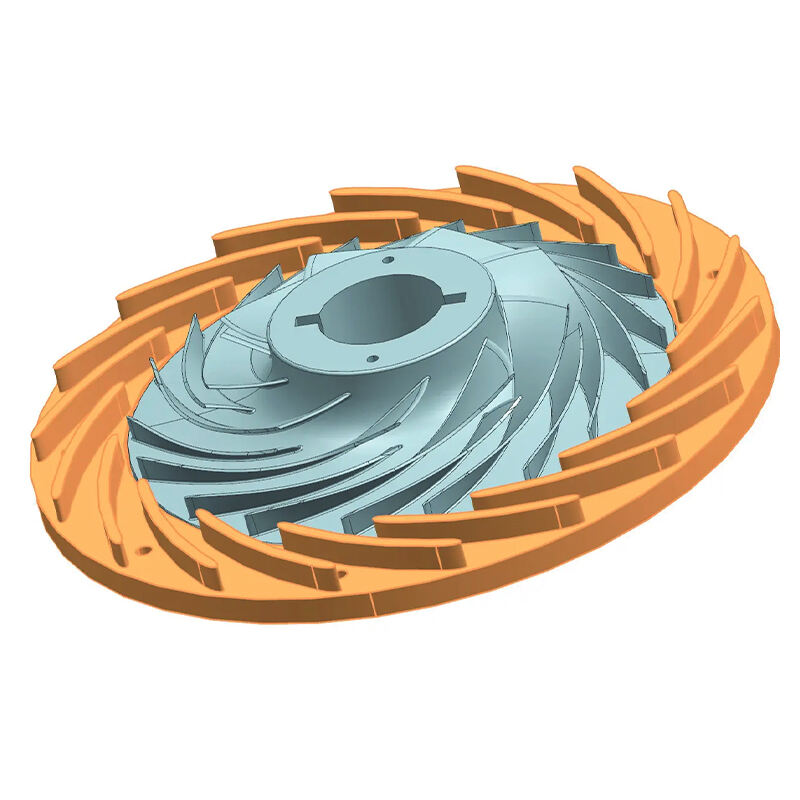

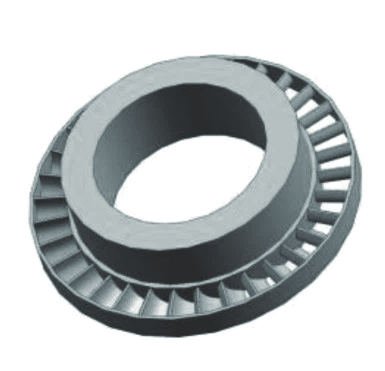

turbine wiel

turbinevleugel

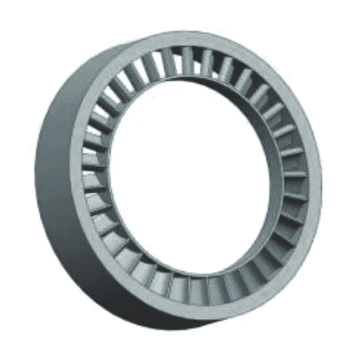

Drukring

compressorblad

Gidsvinnen

Verspreider

SEGMENT

Turbine Rotor

Turbine Stator

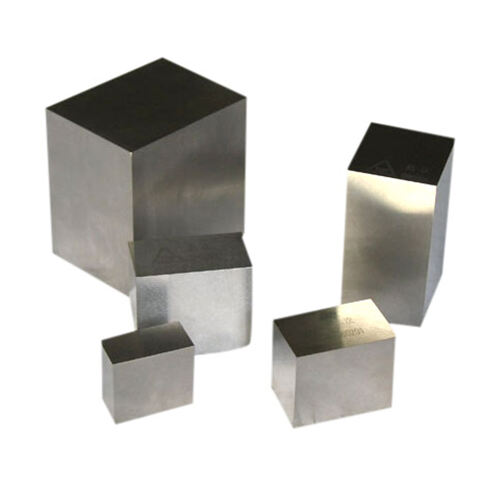

Stellietplaat

Stelliet pijp

Stelliet staaf

Stellite bout en moer

Stellite-bevestigingsmiddelen

Stelliet draad

Lente

A volgens tekeningen of monsters

Nominale samenstelling (Massa %) en fysische eigenschappen

| Co | cr | mo | C | Ik | Overig | Hardheid** | dichtheid | Smeltbereik |

| Basis | 26-29 | 4.5-6.0 | <0.35 | <3.0 | Fe, Si, Mn | 27-40 HRC**290-430 HV** | 8.33 g/cm30.301 lb/in3 | 1295-1435ºC2360-2615ºF |

Stellite-legeringen zijn een groep kobalt-chroomlegeringen die bekend staan om hun uitzonderlijke slijtvastheid, hogetemperatuurprestaties en corrosiebestendigheid. Hier is een overzicht van Stellite:

samenstelling:

Stellite-legeringen bestaan voornamelijk uit kobalt (ongeveer 50-65%) en chroom (ongeveer 25-30%), met variërende verhoudingen van wolfraam, koolstof en andere elementen, afhankelijk van de kwaliteit. Deze legeringselementen geven Stellite-legeringen een unieke combinatie van eigenschappen.

Slijtvastheid:

Stellite-legeringen staan bekend om hun uitstekende slijtvastheid, waardoor ze geschikt zijn voor toepassingen waarbij componenten onderhevig zijn aan abrasieve slijtage, erosie en glijdend contact. Ze worden doorgaans gebruikt in omgevingen met veel slijtage, zoals snijgereedschappen, zaagtanden, klepzittingen en pompcomponenten.

Hoogtemperatuurprestaties:

Stellite behoudt zijn mechanische eigenschappen bij hoge temperaturen, waardoor het hoge temperaturen kan weerstaan zonder significant verlies van sterkte of hardheid. Dit maakt Stellite-legeringen geschikt voor toepassingen met hoge temperaturen, zoals gasturbinecomponenten, ovencomponenten en uitlaatkleppen.

Corrosiebestendigheid:

Stellite-legeringen vertonen een goede corrosiebestendigheid in verschillende omgevingen, waaronder zure en alkalische oplossingen, evenals gassen met hoge temperaturen en gesmolten zouten. Deze corrosiebestendigheid maakt Stellite-legeringen geschikt voor gebruik in chemische verwerking, maritieme techniek en olie- en gasproductie.

Veelzijdigheid:

Stellite-legeringen zijn verkrijgbaar in verschillende kwaliteiten en vormen, waaronder poeders voor thermische spuitcoatings, gietstukken en smeedstukken zoals staven en platen. Deze veelzijdigheid maakt het mogelijk om de meest geschikte kwaliteit en vorm van Stellite-legering voor een specifieke toepassing te selecteren.

Toepassingen:

Stellietlegeringen worden veel gebruikt in de lucht- en ruimtevaart, automobielindustrie, olie- en gasindustrie, energieopwekking en productie-industrie. Ze worden veel gebruikt in componenten die slijtvastheid, hoge temperatuurprestaties en corrosiebestendigheid vereisen.

luchtvaart

Auto- en motorfietsproductie

Chemische industrie

Maritieme techniek

Ons professionele verkoopteam wacht op uw consultatie.