Hastelloy C-2000 (N06200, 2.4675) Hastelloy ir nikla bāzēta augsttemperatūras alīgais, kas sastāv no nikla, molibdēna, hroms un citi elementi, ar nikla saturu aptuveni 55%.

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.01 | 0.08 | 0.50 | 0.020 | 0.080 | 23.0 | 16.0 | - | |

| Citi | N≤ | Al≤ | Ti≤ | Fe≤ | Co≤ | V≤ | W≤ | Nb≤ |

| - | - | - | - | - | - | - | - |

Produkts

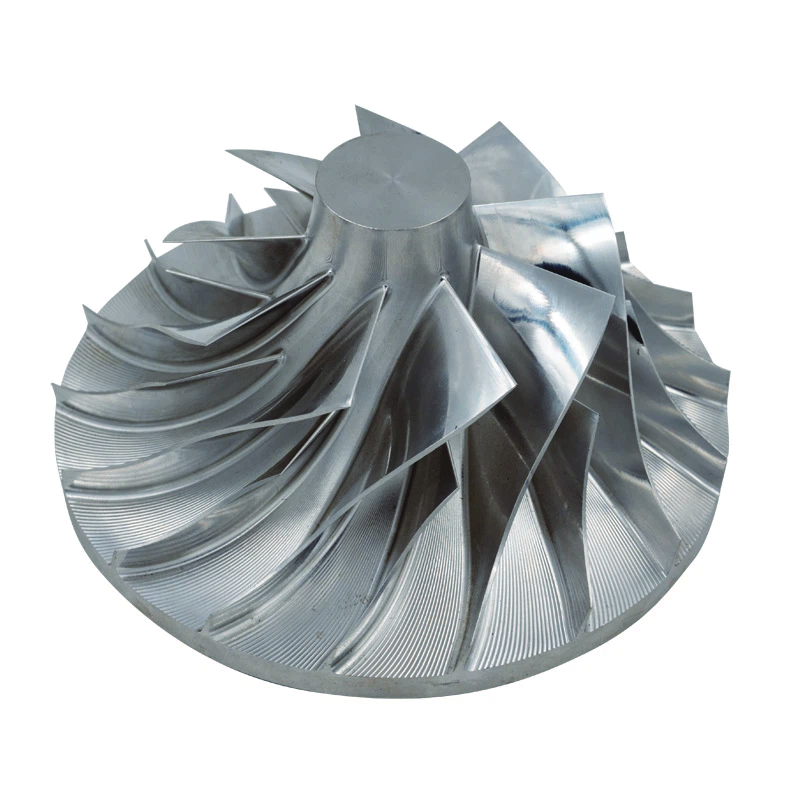

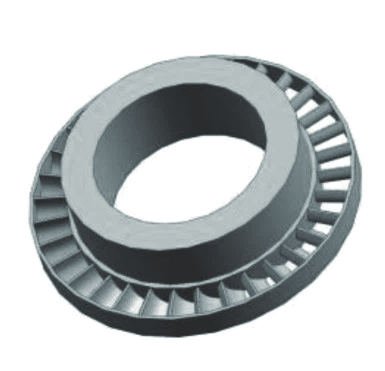

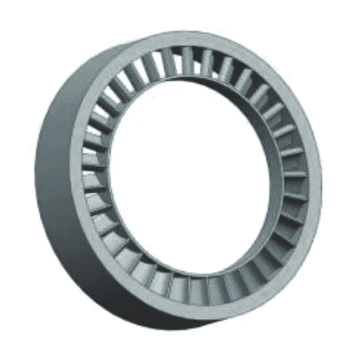

turbīnas rite

turbinas loksne

Trīsbraucējs

tūkšņa loksne

Līdzinājošie vāki

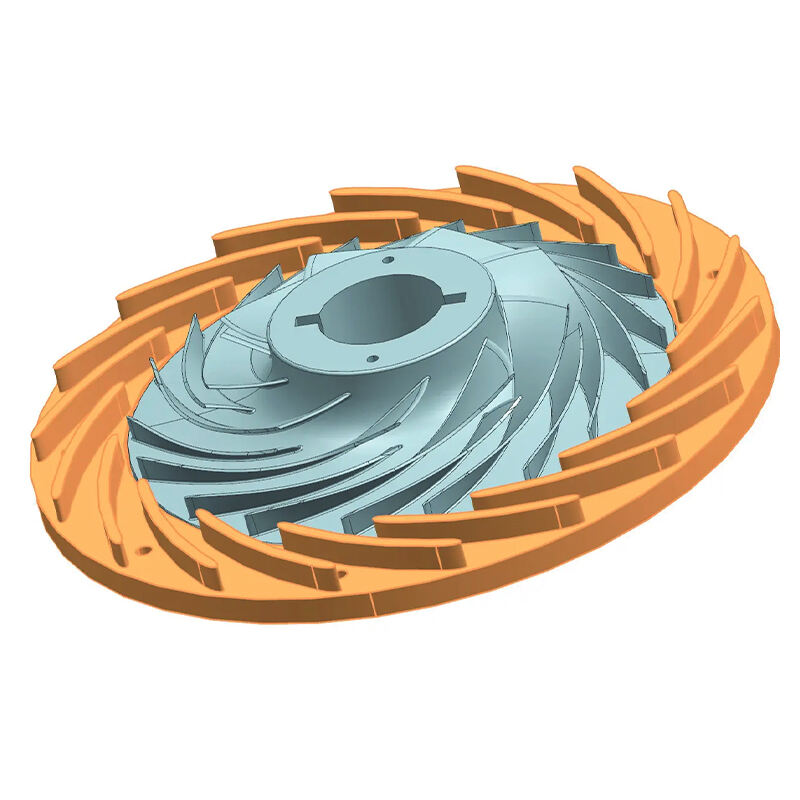

disfūzors

segmenta

Turbīnas rotoris

Turbīnas stators

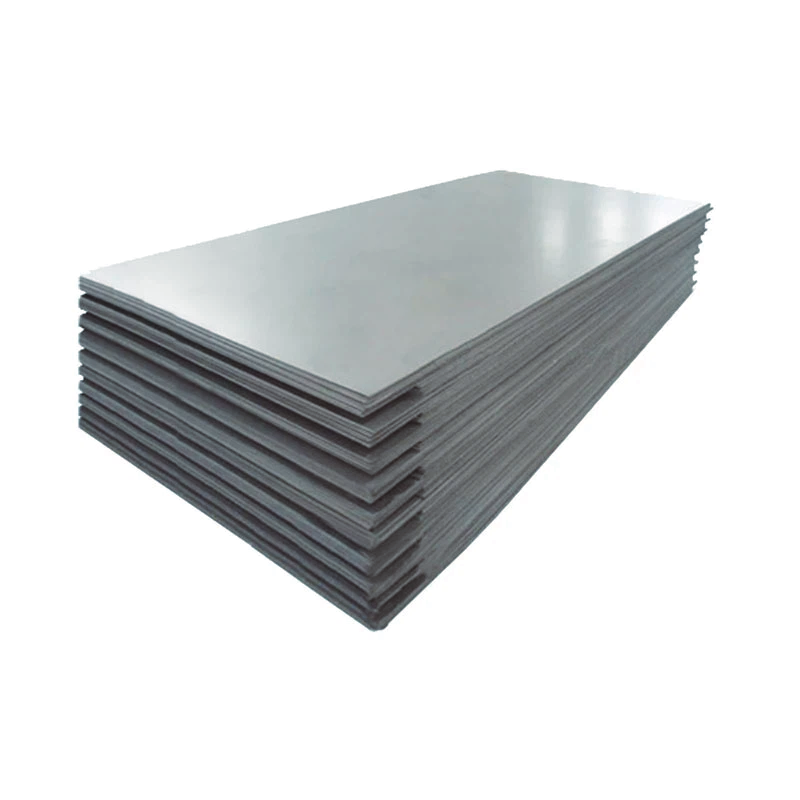

Hastelloy lapas

Hastelloy caurule

Hastelloy stiebis

Hastelloy cūkura un burka

Hastelloy skrējvieli

Hastelloy kabells

Pavasaris

A Saskaņā ar zīmējumiem vai paraugiem

Hastelloy ir vēl viena niklaļbāzes superaloga ģimene, kas pazīstama ar savu izcilu korozijas atbalstu un augstu temperatūru spēku. Šeit ir pārskats par Hastelloy:

Korozijas izturība:

Tikpat kā Inconel, Hastelloy alogi tiek novērtēti par savu izcilo resistenci pret koroziju dažādos agresīvos vidus, tostarp skābekļos, hlorīdossulfīdos un oksidējošajos un reducējošajos apstākļos. Šī korozijas resistence padara Hastelloy piemērotu izmantošanai kimiskās pārstrādes, piesārņojuma kontroles un jūras lietotnes.

Augstu temperatūru darbība:

Hastelloy alogi saglabā savu mehānisko spēku un integritāti augstās temperatūras apstākļos, kas tos padara piemērotiem izmantošanai augstās temperatūras vidē, piemēram, gāzes turbinēs, kosmosa komponentos un rūpnieciskajos krāsnīcās.

Aliejuma sastāvdaļas:

Hastelloy ligavas parasti sastāv no nikla kā galvenajiem elementiem, kā arī nozīmīgās daudzums cromas, molibdana un citu elementu, piemēram, kobalta, wolfrāma un dzelzs. Šie piesardzības elementi iegūst ligavām viņu unikālos īpašumus, tostarp korozijas atbalsta un augstu temperatūru spēku.

Universālums:

Hastelloy ligavas ir pieejamas dažādos grados, katrs pielāgots noteiktām lietojumprogrammām un darbības apstākļiem. Parastie gradi ieskaita Hastelloy C-276, Hastelloy C-22, Hastelloy X un Hastelloy B-2, kā arī citus. Šie gradi piedāvā īpašumu diapazonu, kas piemērots dažādiem vide un nolaidu.

Lietojumprogrammas:

Hastelloy ligavas plaši tiek izmantotas rūpju, piemēram, zālēšanas procesā, petrochemijā, naftas un gāzes, aviācijā, piesārņojuma kontroles un farmaceitiskajā nozarē. Tās tiek izmantotas aparātos, piemēram, reaktoru, siltummainītāju, vērtēm, pumpiem un caurullu sistēmās, kur korozijas atbalsts un augstu temperatūru veiktspēja ir kritiska.

Fabrikācija:

Hastelloja aliaži var tikt izgatavoti dažādās formās, ieskaitot lapas, plāksnes, stieņus, kabeltroses, caurules un formējumus, kas ļauj ražot sarežģītus komponentus, pielāgotus konkrētiem piemēriem.

Kopumā Hastelloja aliaži tiek augsti novērtēti savā izcilajā korozijas atbalstībā, augstā temperatūrā spēcīgi un daudzveidīgi, kas tos padara par neaizstājamiem materiāliem nozarēs, kur bieži sastopamas grūtas vides un prasīgas darbības apstākļi.

Aviācijas joma

Automobiļu un motociklu ražošana

Ķīmijas industrijas

Jūras inženierija

Mūsu profesionālā pārdošanas komanda gaida jūsu konsultāciju.