Stellite 19 resiste a impatti severi e ha un'eccellente durezza al rosso, il che lo rende adatto per applicazioni come utensili da taglio, componenti macchina, corsie di cuscinetti a alta temperatura, dischi diugello e rulli per levigatura.

Lega Stellite 19

Composizione nominale (Percentuale di massa %) e proprietà fisiche

| co | cr | W | C | Sì | Altri | Durezza | densità | Intervallo di fusione |

| Base | 31 | 10.5 | 1.9 | 1.0 | Ni, Fe | 51-53 HRC | 8.36 g/cm30.302 lb/in3 | 1239-1299ºC2263-2370ºF |

Gli alleghi a base di cobalto Stellite sono costituiti da carburi complessi nella matrice dell'allaccio. Sono resistenti all'usura, all'abrasione e alla corrosione e mantengono queste proprietà a temperature elevate. La loro eccellente resistenza all'usura è principalmente attribuibile alle proprietà intrinseche uniche della fase dura di carburo dispersa nella matrice di lega CoCr.

Una delle proprietà distintive del Stellite 19 è la sua capacità di rimanere forte sotto il calore rosso. Ciò rappresenta un intervallo di temperature compreso tra 932 e 1562°F. La resistenza all'impatto del Stellite 19 è paragonabile a quella dell'acciaio ad alta velocità, ma la sua durezza al rosso è superiore. Il Stellite 19 può essere utilizzato a velocità superiori rispetto all'HSS. L'eccellente resistenza alla corrosione da parte di molti comuni agenti chimici e le sue proprietà antiusura consentono di utilizzarlo in modo economico quando si trattano materiali come plastica e gomma, liberando gli agenti corrosivi utilizzati nel processo di produzione.

Prodotto

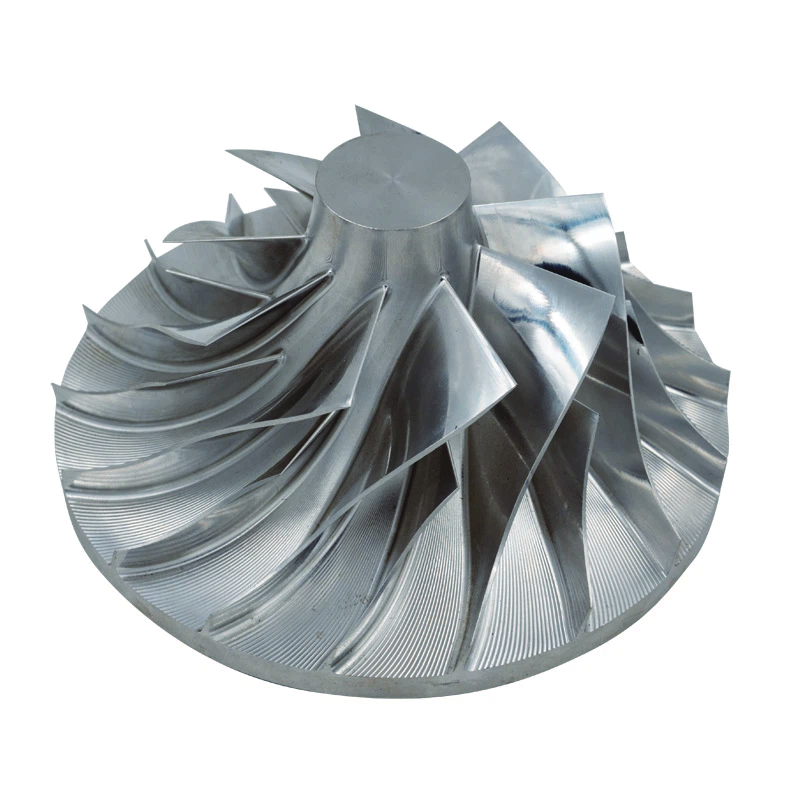

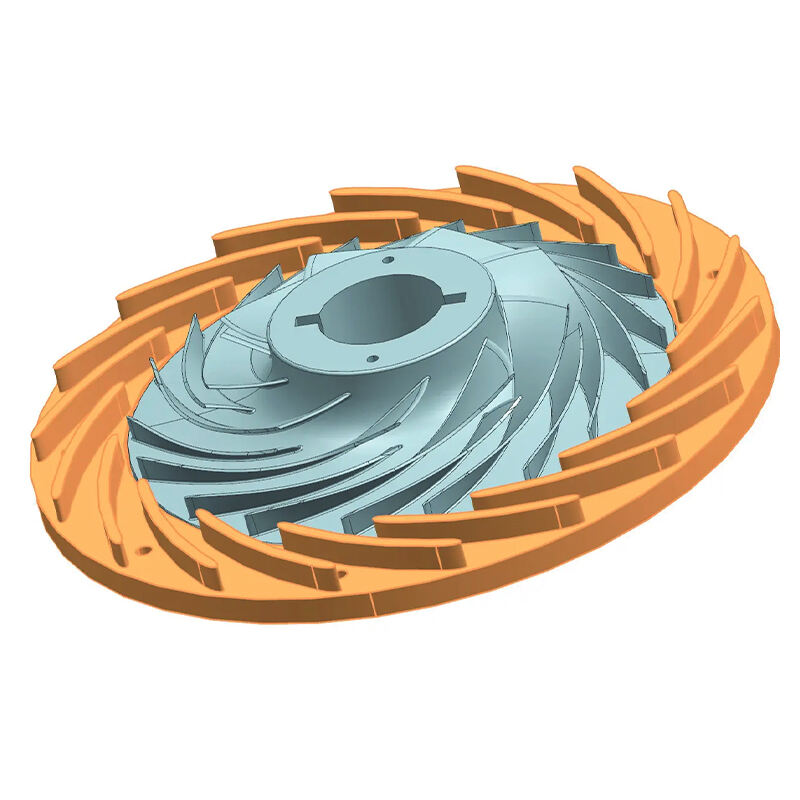

turbine wheel

pala turbine

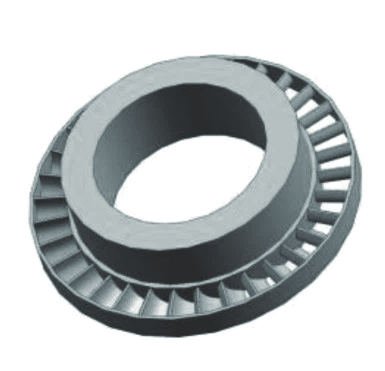

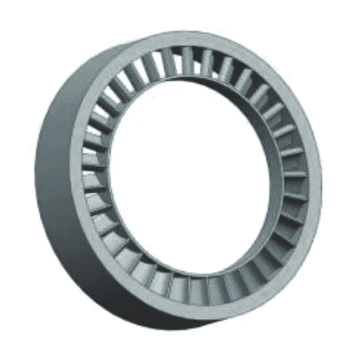

Anello di ugelle

pala del compressore

Vane guida

Diffusore

SEGMENTO

Rottore della turbina

Statore della turbina

foglia Stellite

tubo Stellite

asta Stellite

bullone e dado Stellite

Stellite Fasteners

Stellite wire

Primavera

A Secondo disegni o campioni

Gli alleghi Stellite sono un gruppo di leghe a base di cobalto-cromo noti per la loro eccezionale resistenza all'usura, le prestazioni a temperature elevate e la resistenza alla corrosione. Ecco un panorama generale degli Stellite:

Componente:

Le leghe Stellite sono costituite principalmente da cobalto (circa il 50-65%) e cromo (circa il 25-30%), con proporzioni variabili di tungsteno, carbonio ed altri elementi a seconda del grado. Questi elementi di lega conferiscono alle leghe Stellite una combinazione unica di proprietà.

Resistenza all'usura:

Gli alleghi Stellite sono noti per la loro eccellente resistenza all'usura, il che li rende adatti per applicazioni in cui i componenti sono sottoposti a usura abrasiva, erosione e contatto scorrevole. Vengono generalmente utilizzati in ambienti ad alta usura come strumenti di taglio, denti di sega, sedili di valvola e componenti di pompa.

Prestazioni a temperature elevate:

Lo Stellite mantiene le sue proprietà meccaniche a temperature elevate, permettendogli di resistere a temperature elevate senza una significativa perdita di forza o durezza. Ciò rende gli alleghi Stellite adatti per applicazioni a temperature elevate come componenti di turbine a gas, componenti di forno e valvole di scarico.

Resistenza alla corrosione:

Gli alleghi Stellite mostrano una buona resistenza alla corrosione in una varietà di ambienti, inclusi soluzioni acide e alcaline, nonché gas a temperature elevate e sali fusi. Questa resistenza alla corrosione rende gli alleghi Stellite adatti per l'uso nella lavorazione chimica, ingegneria marittima e produzione di petrolio e gas.

Versatilità:

Gli alleghi Stellite sono disponibili in una varietà di gradi e forme, inclusi polveri per rivestimenti termici, fonderie e forgiature come barre e piastre. Questa versatilità consente la selezione del grado e della forma più appropriati dell'alleghio Stellite per un'applicazione specifica.

Applicazioni:

Gli alleghi Stellite vengono utilizzati ampiamente nei settori aerospaziale, automobilistico, petrolchimico, generazione di energia e manifatturiero. Vengono ampiamente utilizzati in componenti che richiedono resistenza all'usura, prestazioni a temperature elevate e resistenza alla corrosione.

Il nostro team di vendita professionale è in attesa della tua consulenza.