Home / PRODUCTS / Turbine Accessories / Bolts

The following are the characteristics and introduction of some common high-temperature alloy bolts and nuts:

Material selection:

High-temperature alloy bolts and nuts are often made from materials such as nickel-based alloys or titanium alloys because these materials have excellent resistance to high temperatures, corrosion, and oxidation.

High temperature resistance:

These bolts and nuts can operate in extreme high temperature environments, often able to withstand temperatures of hundreds of degrees Celsius, even up to over 1,000 degrees Celsius.

Anti-oxidation properties:

The materials of high-temperature alloy bolts and nuts have good anti-oxidation properties and can work at high temperatures for a long time without failure due to oxidation.

High strength:

Despite being exposed to high temperatures, these bolts and nuts can still maintain sufficient strength to ensure the reliability and stability of the connection.

Sealing performance:

Since high-temperature and high-pressure environments usually require strict sealing performance, high-temperature alloy bolts and nuts are usually designed to provide reliable sealing structures to prevent media leakage.

Corrosion resistance:

These connections also generally have good corrosion resistance and can be used in harsh working environments for a long time without being affected by corrosion.

| NominalSize | d | S | k | ||||||

| Major Diameter | Width Across Flats | Head Height | |||||||

| Min. | Max | Max. | Min | Grade A | Grade B | ||||

| Grade A | Grade B | Min | Max. | Min. | Max | ||||

| M3 | 2.874 | 2.980 | 5.5 | 5.32 | - | 1.88 | 2.12 | - | - |

| M4 | 3.838 | 3.978 | 7 | 6.78 | - | 2.68 | 2.92 | - | - |

| M5 | 4.826 | 4.976 | 8 | 7.78 | - | 3.35 | 3.65 | - | - |

| M6 | 5.794 | 5.974 | 10 | 9.78 | - | 3.85 | 4.15 | - | - |

| M7 | 6.794 | 6.974 | 11 | 10.73 | - | 4.65 | 4.95 | - | - |

| M8 | 7.760 | 7.972 | 13 | 12.73 | - | 5.15 | 5.45 | - | - |

| M10 | 9.732 | 9.968 | 17 | 16.73 | - | 6.22 | 6.58 | - | - |

| M12 | 11.701 | 11.966 | 19 | 18.67 | - | 7.32 | 7.68 | - | - |

| M14 | 13.682 | 13.962 | 22 | 21.67 | - | 8.62 | 8.98 | - | - |

| M16 | 15.682 | 15.962 | 24 | 23.67 | 23.16 | 9.82 | 10.18 | 9.71 | 10.29 |

| M18 | 17.623 | 17.958 | 27 | 26.67 | 26.16 | 11.28 | 11.72 | 11.15 | 11.85 |

| M20 | 19.623 | 19.958 | 30 | 29.67 | 29.16 | 12.28 | 12.72 | 12.15 | 12.85 |

| M22 | 21.623 | 21.958 | 32 | 31.61 | 31 | 13.78 | 14.22 | 13.65 | 14.35 |

| M24 | 23.577 | 23.952 | 36 | 35.38 | 35 | 14.78 | 15.22 | 14.65 | 15.35 |

| M27 | 26.577 | 26.952 | 41 | - | 40 | - | - | 16.65 | 17.35 |

| M30 | 29.522 | 29.947 | 46 | - | 45 | - | - | 18.28 | 19.12 |

| M33 | 32.522 | 32.947 | 50 | - | 49 | - | - | 20.58 | 21.42 |

| M36 | 35.465 | 35.940 | 55 | - | 53.8 | - | - | 22.08 | 22.92 |

| M39 | 38.465 | 38.940 | 60 | - | 58.8 | - | - | 24.58 | 25.42 |

Bolts and nuts perform many important functions, including:

Connecting engine components:

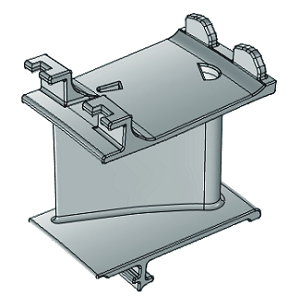

An engine is a complex system consisting of many parts, and bolts and nuts are used to connect these parts, such as cylinder head, cylinder block, crankcase, connecting rods, pistons, etc. They ensure the correct alignment and secure connection of the individual components to form a complete engine structure.

Bearing mechanical loads:

During engine operation, various components will be subject to mechanical loads caused by factors such as the combustion process and motion inertia. Bolts and nuts are responsible for transmitting these loads and ensuring that the mechanical connection between the various components of the engine is strong and reliable.

Sealing:

The high temperature and high pressure environment inside the engine requires good sealing performance to prevent the leakage of gas and liquid. Proper installation and pre-tightening of bolts and nuts can ensure the sealing inside the engine and prevent gas or liquid from leaking during operation.

High temperature resistance:

The engine will generate high temperatures when working, especially in the combustion chamber and exhaust system. Bolts and nuts need to be made of materials that can withstand high temperatures to ensure their stable performance, safety and reliability in high temperature environments.

Disassembly and maintenance:

The engine needs to be maintained and inspected regularly. The design of bolts and nuts should be convenient for disassembly and assembly to ensure the smooth progress of the repair process.

product

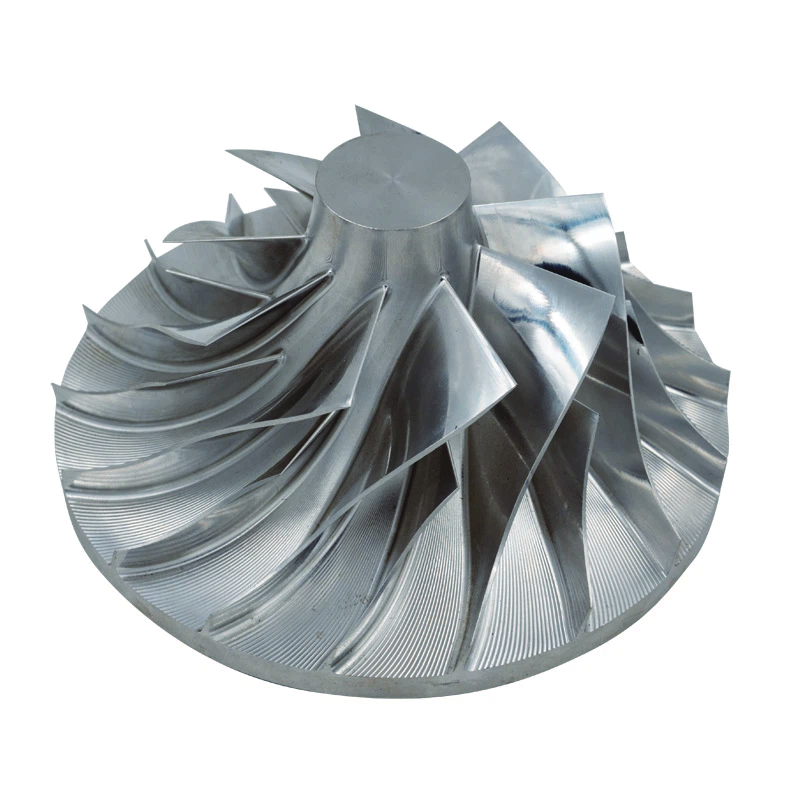

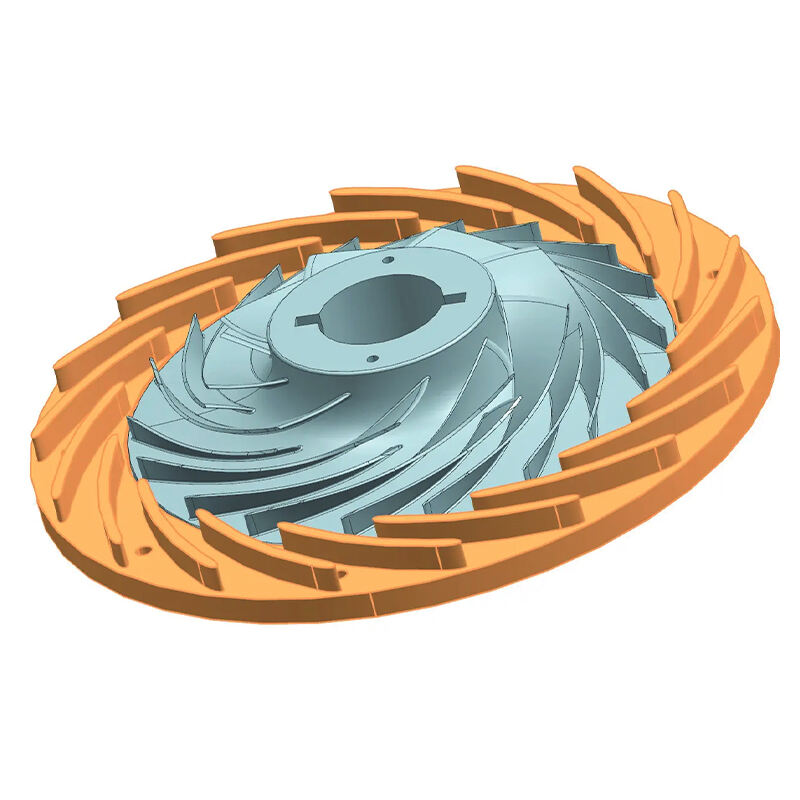

turbine wheel

turbine blade

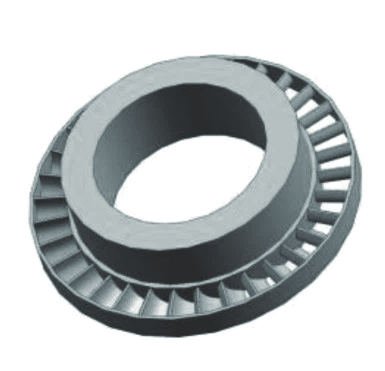

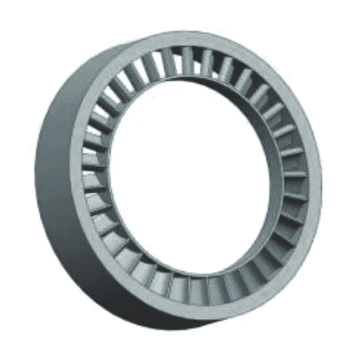

nozzle ring

compressor blade

guide vanes

diffuser

Segment

Turbine Rotor

Turbine Stator

Titanium sheet

Titanium pipe

Titanium rod

Titanium bolt and nut

Titanium Fasteners

Titanium wire

spring

According to drawings or samples

High-temperature alloy bolts and nuts are suitable for various applications that require working in high-temperature environments.

Aerospace:

In the aerospace industry, engines and propulsion systems are required to withstand extreme temperatures and pressures. High-temperature alloy bolts and nuts are widely used in the connection and fixation of aircraft engines, rocket engines and other components to ensure the structural integrity and stability of the system.

Energy industry:

In the energy field, equipment such as turbines and gas turbines in power plants usually need to operate in high-temperature and high-pressure working environments. High-temperature alloy bolts and nuts are used to connect turbine blades, discs, shafts and other components, as well as gas turbine gas nozzles, turbine blades and other components.

Automotive industry:

In the automotive industry, turbochargers and exhaust systems require the use of high-temperature alloy bolts and nuts to connect turbine blades, turbine housings and other components to ensure safety and reliability under high-temperature engine operating conditions.

Petroleum and chemical industry:

In the field of petroleum and chemical industry, some production equipment needs to withstand high temperature and high pressure working environment, such as oil refining units, chemical reactors, etc. High-temperature alloy bolts and nuts are used to connect various components of these equipment to ensure safe operation and production efficiency of the equipment.

| materila | Inconel625 inconel600 inconel718 Monel 400,Monel K500, Hastelloy C22 Hastelloy C276 ect. | |||||||

| Service | Drawing Custom | |||||||

| range | Bolt, nut, turbine blade ,high temperature alloy accessories and so on | |||||||

| Inconel 625 | Corrosion Resistance | Sulfuric AcidHydrochloric AcidPhosphoric Acid | ||||||

| Benefits | Very good corrosion resistance at elevated temperaturesInconel 625 Hex BoltsHigh temperature stability up to 2200°F (982°C)High strength material with excellent toughness at elevated temperaturesInch and metric sizes (EN 2.4856 DIN 933, DIN 931 | |||||||

| Inconel 625 Specifications | AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE MR0175-3, UNS N06625, Werkstoff 2.4856 | |||||||

| Inconel 718 | Applications | Uses for Inconel 718 tend to be in the field of gas turbine components and cryogenic storage tanks. Jet engines, pump bodies and parts, rocket motors and thrust reversers, nuclear fuel element spacers, hot extrusion tooling. Other popular uses are high strength bolting, and down hole shafting. | ||||||

| Mone1400 | Feature | with high strength and excellent corrosion resistance in a range of media including seawater,hydrofluoric acid,sulfuric acid,and alkalies | ||||||

| Applications | Used for marine engineering,chemical and hydrocarbon processingequipment,valves,pumps,shafts,fittings,fasteners,and heat | |||||||

material

Inconel material Hastelloy material Stellite material Titanium material Nimonic Alloy material

Our professional sales team are waiting for your consultation.