Video

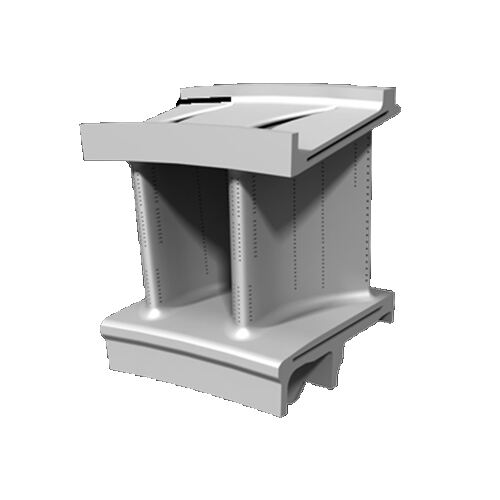

Ovo su neki ključni aspekti vodena vratara turbine:

Upravljanje smjerom:

Vodene vratara turbine postavljaju se pažljivo kako bi usmjerile fluid pod optimalnim kutovima na rotirajuće lopatica turbine. Upravljanjem smjerom i brzinom toka, vratara osiguravaju učinkovit prijenos energije na rotor turbine.

Pretvorba energije:

Dok fluid prolazi kroz turbine, vratara pomažu u pretvorbi kinetičke energije fluida u mehaničku energiju. Vratara maksimiziraju izlučivanje energije iz fluida usmjerljivši ga pod pravim kutem i brzinom preko lopatica turbine.

Raspodjela opterećenja:

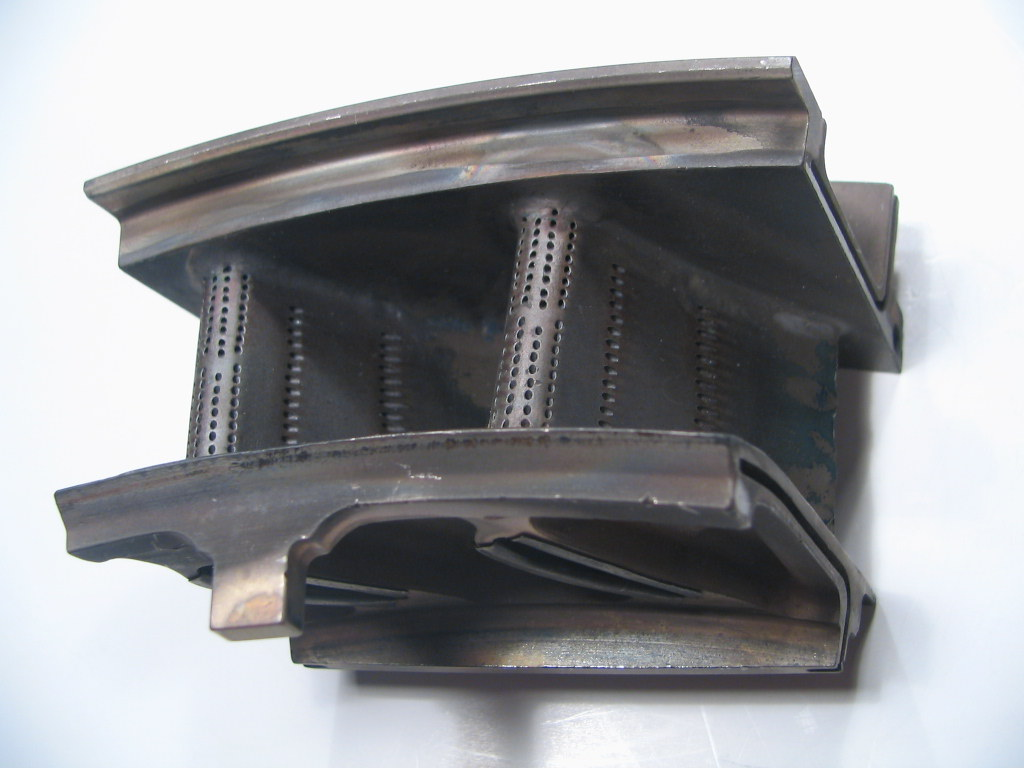

Vodene lamelje raspoređuju fluid ravnomjerno preko rotora turbine, osiguravajući jednoliko opterećenje i smanjujući rizik od neravnomjernog oštećenja ili štetica turbinim listovima. To pomaže u održavanju čistoće i performansi turbine tijekom njezina radnog vijeka.

Optimizacija učinkovitosti:

Pristojno dizajnirane vodene lamelje su ključne za optimizaciju radne učinkovitosti turbine. One pomažu smanjiti gubitke energije zbog turbulentnosti, odjeljivanja ili neefikasnih strujnih uzoraka, time poboljšavajući ukupnu učinkovitost i performanse.

Stabilnost i kontrola:

Vodene lamelje turbine sprečavaju nestabilnosti poput stajala ili prigušaja, time doprinosi stabilnosti i kontroli rada turbine. Vodene lamelje osiguravaju suvereno djelovanje u raznim radnim uvjetima kontroliranjem strujnih parametara.

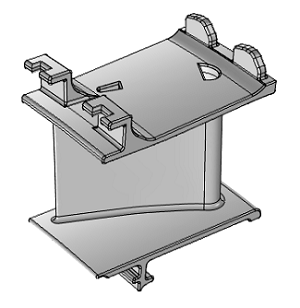

Aerodinamički dizajn:

Vodene pločice su precizno dizajnirane kako bi se postigli određeni aerodinamički karakteristici, poput optimalnog kuta napada, duljine korde i zakrivljenosti. Napredne simulacije i testiranje računalne dinamike fluida (CFD) često se koriste za optimizaciju dizajna s ciljem postizanja maksimalne učinkovitosti.

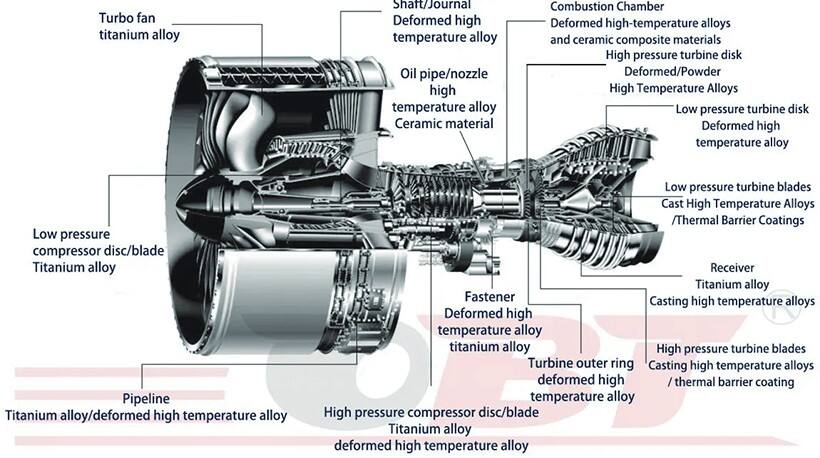

Materijal

Inconel materijal Hastelloy materijal Stellite materijal Titanij materijal Nimonic legura materijal

Osobine

Glavna funkcija vodenih pločica je kontrola toka fluida (poput pare ili plina) koji ulazi u rotator turbine. One usmjeravaju tok fluida na turbine lopatica pod optimalnim kutovima i brzinama, osiguravajući učinkovitu pretvoru energije i maksimiziranje performansi turbine.

Vodene pločice igraju ključnu ulogu u pretvaranju kinetičke energije u mehaničku tijekom prolaska fluida kroz turbine. Usmjeravanjem fluida na turbine lopate, one pomažu u izvlačenju energije iz fluida te poboljšavaju cjelkovitu učinkovitost turbine.

U nekim dizajnima turbine, vodene lamelacemo se mogu prilagoditi kako bi se omogućilo precizna reguliranja parametara toka i optimizacija performansi turbine u različitim radnim uvjetima. Ova prilagodljivost omogućuje turbini da održava optimalnu učinkovitost u širokom rasponu radnih uvjeta.

Vodene lamelae su precizno dizajnirane kako bi se postigle specifične aerodinamičke karakteristike poput optimalnog kuta napada, duljine korde i zakrivljenosti. Ova optimizacija dizajna pomaže u smanjenju gubitaka energije uzrokovanih turbulentnošću, odsljeđivanjem ili neefikasnim oblicima toka, čime se povećava ukupna učinkovitost.

Vodene lamelae raspoređuju fluid ravnomjerno preko rotora turbine, osiguravajući jednoliko opterećenje i smanjujući rizik od neravnomjernog iznosenja ili štete na lopaticama turbine. To pomaže u održavanju integriteta i performansi komponenti turbine tijekom njihova radnog vijeka.

Pristojno dizajnirane vodene ploče pomažu sprečavanju nestabilnosti poput stajala ili prigušaja, time doprinosi stabilnosti i kontroli rada turbine. Osiguravaju suvu radnju u različitim radnim uvjetima i poboljšavaju pouzdanost i sigurnost sustava turbine.

Aerokosmičko područje: Vodene ploče turbine široko se koriste u aerokosmijskim motorima, uključujući reaktivne motore, turboventilatorske motore itd. Nose turbine lopice koje se okreću kako bi privodele kompresor, turbinu i druge povezane komponente za obezbeđivanje snage potrebne za podršku leta zrakoplova.

Energetska industrija: U energetskom području, vodene ploče se koriste u parne turbine, plinske turbine, parne turbine i druge opreme u različitim vrstama generirajućih jedinica. Pretvaraju plinsku ili parnu energiju u električnu energiju za upotrebu u elektrocentralama okretanjem rotorja generatora.

Industrijsko područje: U industrijskom području, vodene lamelle turbine koriste se u različitim vrstama turbomjehanizamskog opreme, poput kompresora, ventilatora, pumpe itd. One omogućuju stiskanje, prijevoz ili cirkulaciju tečnosti ili plinova putem rotacije i koriste se za prijenos snage i pretvoru energije u industrijskim procesima proizvodnje, izrađivanja i obrade.

Industrijsko područje: U području izlučivanja energije, vodene lamelle turbine koriste se u različitoj turbinovoj opremi, kao što su naprave za izlučivanje nafte i plina, hidroelektrične naprave za proizvodnju električne energije itd. One pogone povezane naprave putem rotacije kako bi se poboljšala učinkovitost izlučivanja energije i produktivnost.

Područje prometa: Vodene lamelle turbine koriste se u turbozagonskim sustavima automobilskih motora kako bi se poboljšala snaga motora i učinkovitost goriva, te također u turbozagonskim sustavima za prijevozna vozila poput vlaka i brodova.

Brodogradnja: Vodene lamelle turbine koriste se u energetskim uređajima broda, kao što su turbozagonski sustavi i pomorske turbine, kako bi se pružila snaga za vođenje broda.

| Materijal | Inconel600,Inconel625,Inconel718,Inconel X-750,Monel 400,Monel K500Hastelloy G-30,Hastelloy X,Hastelloy B-2,Hastelloy C-22,Hastelloy C-276GH4169,GH4145,GH3030,GH2136,GH5188 |

| PRIMJENA | Prometna ventilacije, vjetroelektrane, brodogradnja, termoelektrane, nuklearne elektrane, reaktivni motori, turbojet motori |

| Osobine | Otpornost na visoke temperature, otpornost na oksidaciju, otpornost na koroziju, performanse termičke umora, dobra mehanička svojstva, otpornost na iznosenje |

| Primjenjiv model | SST-040,SST-060,SST-110,SGT-100,SGT-200,SGT-400GE Frame 5,GE Frame 6,GE Frame 7,GE9X,GE LM2500,GE LM6000MS3002,MS5001NT,MS5001STD,MS5001,MS5002,MS6001,MS7001,MS9001,MS9002 |

Naš profesionalni prodajni tim čeka na vašu konzultaciju.