Video

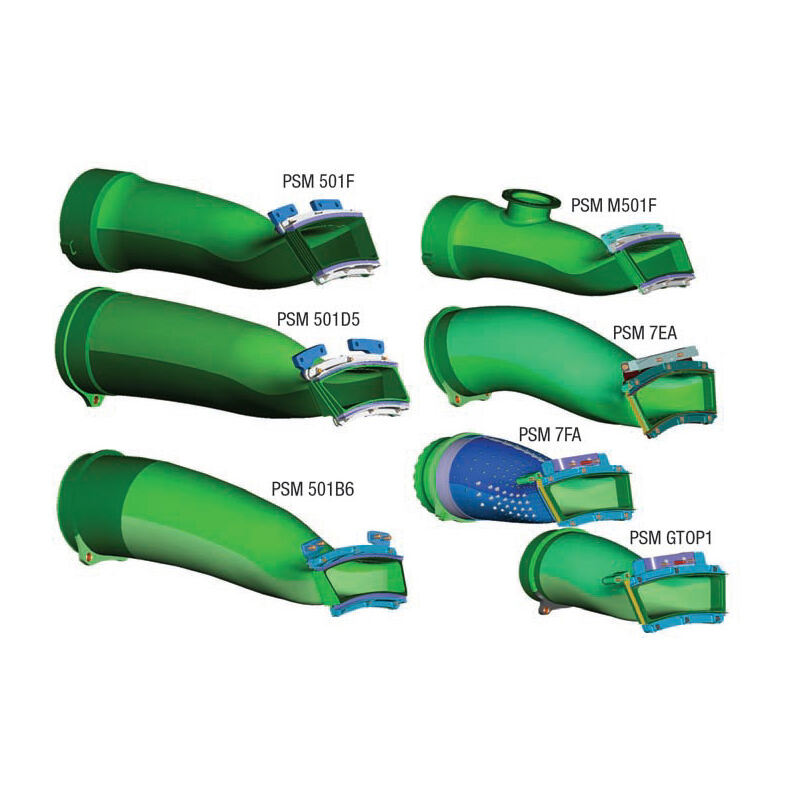

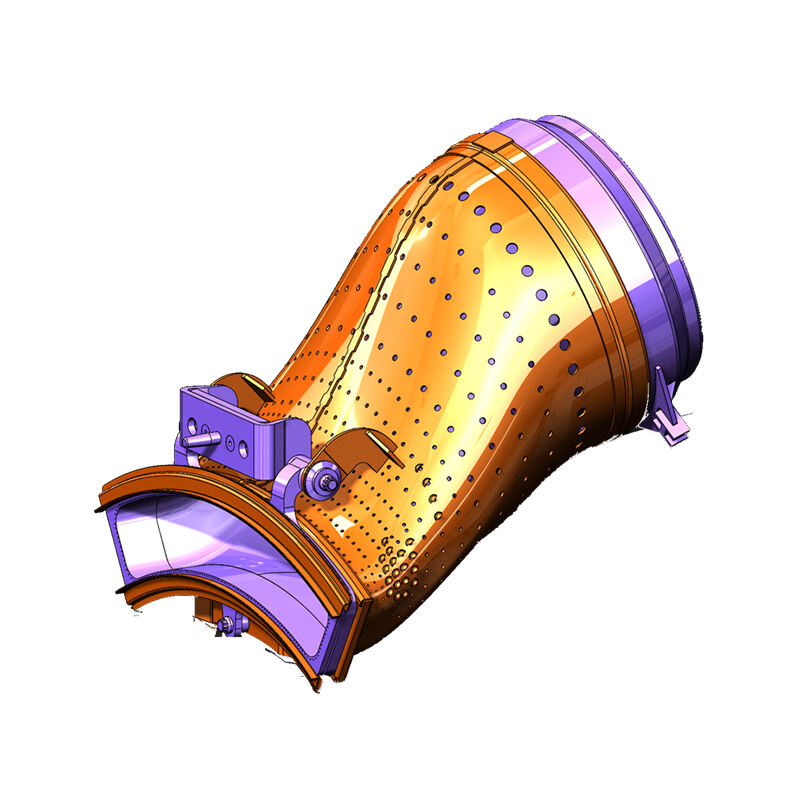

Transition section: the key bridge connecting the combustion chamber and the turbine

The shape of the transition section is usually a gradually changing pipe. Its cross-sectional area gradually increases from the compressor to the combustion chamber. This is because the airflow velocity and pressure at the compressor outlet are high, and it is necessary to reduce the airflow velocity by increasing the cross-sectional area so that the airflow can be better mixed with the fuel and stably burned in the combustion chamber. Its length varies according to the overall design and performance requirements of the gas turbine. Generally speaking, its length design should take into account the uniform transition of the airflow and the minimization of pressure loss.

Since the transition section needs to withstand high temperature and pressure, especially the transition section from the combustion chamber outlet to the turbine, it has to face the scouring of high-temperature combustion gas. Therefore, it usually uses high-temperature resistant alloy materials, such as nickel-based alloys. In terms of manufacturing process, precision casting technology may be involved to ensure that its internal surface is smooth and reduce the friction resistance of airflow. At the same time, some transition sections will also adopt the design of internal cooling channels to reduce the temperature of the components by introducing cooling air to ensure its structural integrity and stable performance in high-temperature environments.

During the transition from the compressor to the combustion chamber, the main function is to adjust the speed and pressure of the airflow. The airflow velocity at the compressor outlet is high, while the combustion chamber requires a relatively low-speed airflow to ensure sufficient mixing and stable combustion of fuel and air. The transition section reduces the airflow velocity and the pressure changes accordingly to meet the requirements of the combustion chamber inlet through its gradually changing cross-sectional area. From the combustion chamber to the turbine, the transition section must allow the high-temperature and high-speed gas to enter the turbine evenly to ensure that the turbine can efficiently extract energy from the gas.

The design of the transition section is crucial to ensure uniform airflow. In a gas turbine, both the mixing of fuel and air in the combustion chamber and the work process of the gas in the turbine require uniform airflow distribution. Uneven airflow may lead to problems such as incomplete combustion, local overheating, or uneven force on the turbine blades. The transition section guides the airflow to flow evenly through special internal structures such as guide vanes and gradual wall shapes, thereby improving the performance and reliability of the entire gas turbine system.

The transition section between the combustion chamber and the turbine directly affects the working performance of the turbine. If the transition section cannot evenly guide the high-temperature gas into the turbine, the turbine blades will be subjected to uneven thermal and mechanical stress. This will not only reduce the efficiency of the turbine, but may also cause damage to the turbine blades and shorten the service life of the gas turbine. In addition, the pressure loss in the transition section will also affect the gas pressure at the turbine inlet, thereby affecting the working capacity of the turbine.

Our professional sales team are waiting for your consultation.