Aero engines are marvels of engineering, comprised of hundreds of intricately designed parts, each playing a vital role in converting fuel into thrust. The assembly of these engines is a delicate and complex process, demanding precision, patience, and unwavering attention to detail. A single misplaced part, a loose connection, or a misaligned component can lead to catastrophic consequences, jeopardizing the safety of the aircraft and its occupants. Therefore, every step in the assembly process must be carried out with the utmost care and meticulousness.

Here, we delve into the key considerations and precautions to ensure safe and successful aero engine part assembly:

1. Tool Preparation and Use: A Foundation for Precision

The assembly process relies on a diverse array of specialized tools, ranging from screwdrivers and wrenches to pliers and torque wrenches. Before embarking on any assembly task, a thorough inspection of all tools is crucial. This includes checking for damage, wear, and expiration dates. Damaged or expired tools can compromise the integrity of the assembled parts, potentially leading to malfunctions or even catastrophic failures.

2. Assembly Sequence: A Choreographed Symphony of Parts

Aero engine assembly is not simply about putting parts together; it’s a carefully orchestrated sequence of operations. Each component must be installed in a specific order, following the precise instructions outlined in the official technical documents. These documents provide detailed guidance on the installation steps, technical requirements, and appropriate tools for each component. Adherence to this strict sequence ensures that each part is fixed reliably, neither too tight nor too loose, guaranteeing optimal performance and preventing premature wear or damage.

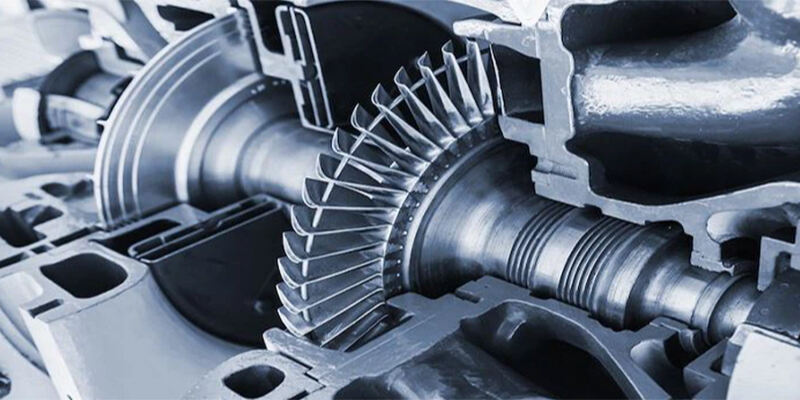

3. Angle and Orientation: The Critical Dance of Alignment

Many aero engine parts require specific angles and orientations for proper installation. Take, for example, the installation of a turbine impeller, where the inlet direction must perfectly align with the direction of airflow. Failure to install the impeller at the correct angle can lead to inefficient airflow, reduced engine performance, and even damage to the turbine itself. This meticulous attention to detail ensures that each component functions optimally within the complex system of the engine.

4. Official Directives: The Guiding Principles of Assembly

Official technical documents are the cornerstone of successful aero engine assembly. These documents, meticulously compiled by engineers and technicians, detail every aspect of the assembly process, providing comprehensive information on:

●Installation Steps: Detailed instructions for each component, ensuring correct placement, alignment, and securing.

●Technical Requirements: Precise specifications regarding torque values, clearances, and tolerances for each component, ensuring optimal performance and minimizing the risk of failure.

●Tool Requirements: Specific tools and equipment necessary for each step of the assembly process, ensuring accurate and safe installation.

These documents are not merely guidelines; they are essential blueprints for safe and successful assembly. Following them with meticulous attention to detail, combined with a commitment to accuracy, care, and patience, ensures that the assembled engine meets the highest standards of quality and reliability.

5. Careful Inspection: A Multi-Stage Quality Control Process

Even after meticulous assembly, a thorough inspection is crucial. This is not a single, cursory glance; it is a multi-stage process, ensuring the engine meets the highest standards of quality.

●First Inspection: This inspection takes place after the engine has been assembled but before it is refueled. Every component, every connection, every seal is carefully examined, verifying its correct placement, securing, and alignment.

●Second Inspection: This inspection occurs after the engine has been refueled and the oil has been drained. This allows for a more thorough examination of internal components, ensuring that there are no leaks, loose connections, or other potential problems.

During each inspection, any discrepancies, inconsistencies, or potential issues are promptly addressed. This meticulous approach ensures that only engines meeting the highest quality standards leave the assembly line, ready for their critical role in powering aircraft safely and reliably.

The Importance of Patience and Care

Aero engine assembly is not a task for the impatient or careless. A seemingly minor oversight can lead to major consequences. Through rigorous operation and careful inspection, we ensure that the assembled engines meet the qualified standards, thus ensuring the safety of the aircraft during flight. Each part, every connection, and every detail matters. The commitment to precision and care is not just a guideline; it is a vital safeguard for those who depend on these engines to carry them safely through the skies.

Table of Contents

- 1. Tool Preparation and Use: A Foundation for Precision

- 2. Assembly Sequence: A Choreographed Symphony of Parts

- 3. Angle and Orientation: The Critical Dance of Alignment

- 4. Official Directives: The Guiding Principles of Assembly

- 5. Careful Inspection: A Multi-Stage Quality Control Process

- The Importance of Patience and Care

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

IS

IS