If you remember that time, did it ever come across your mind how airplanes work or do engines and energies generate? The common component for all of them happens to be a nozzle ring!!!!!!! In that respect, nozzle rings are of utmost importance as they govern the amount and velocity of air - ultimately a key to ensuring optimal performance. Let us peek further behind the curtains of nozzle rings and how they improve airflow control for better efficiency;

Importance of Nozzle Rings in Air Flow Control

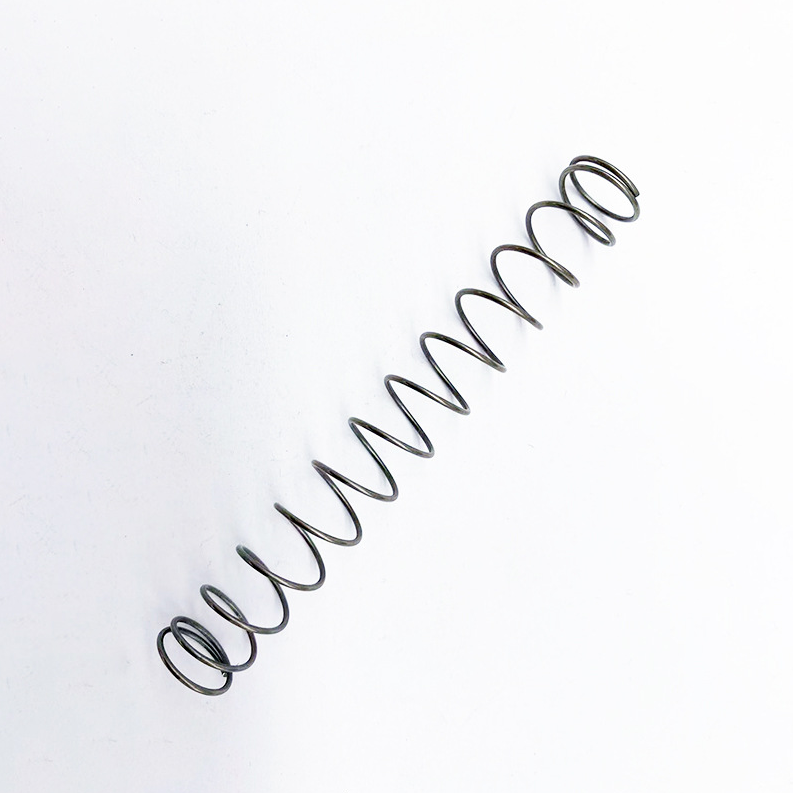

The nozzle rings are designed to control the flow of air. They are primarily responsible for making sure everything runs smoothly and efficiently. These systems would not operate efficiently without these nozzle rings. In summary, by redirecting the airflow sealing_nozzle_rings ensure that it flows in right way. They also ensure correct air pressure in a broad range of applications with many other industries.

They are used for a variety of industries (e.g. energy production and transportation) Parameter(The most important parameter in the nozzle ring is gap). The tools are vital to make the equipment work properly. Airplanes would have a hard time getting up to high speeds, engines wouldn't run smoothly or efficiently, and energy production would be less efficient.

Increased Engine Performance With Nozzle Rings

Nozzle rings are instrumental in maximizing engine efficiency. A very high amount of air is needed for the efficient functioning of engines. They are fuel nozzles that calibrate the air flow accurately This in return helps keep the smooth air intake and engine operation.

Nozzle rings also help in protecting the environment and reducing emissions from engines. All of which help in efficient fuel combustion (less harmful emissions), by regulating air flow.

MAJOR APPLICATION OF NOZZLE RINGS IN INDUSTRIES

Application of nozzle rings is widespread across an array of industrial setup. They help ensure continuous operation by regulating and proper routing of necessary airflow at specific times. The rings are also essential in humanity to control air pressure, which is necessary for a variety of industries.

There are different usages of nozzle rings in industrial sectors. Pneumatic louvers are used to control air flow through machinery and may be subjected to adverse conditions as well, but the valves can also direct airflow in whole heating or cooling systems (in buildings) Poppet valve functions similarly.

Effects of Aircraft Performance due to Nozzle Rings

Aeroengine nozzle rings are quite important for the performance of an aircraft. They are absolutely vital in making sure aircraft can fly faster and higher than conventional engines. If you did not have nozzle rings to precisely control this air, the performance and maneuverability of each aircraft would be limited.

Nozzle rings control the flow of air inside aircraft engines. This way, the engine gets only what it needs for best performance. These rings also help in the aircraft engines by reducing noise and emission.

Importance of Nozzle Rings in the Areas of Energy Production

In terms of the energy production, nozzle rings have become an essential part. Its a Key factor for controlling airflow in the turbines & Generators which is crucial to energy generation efficiency and effectiveness Energy production is less efficient without nozzle rings.

These rings are used in everything from coal-fired power plants to wind turbines. These essential units help in the smooth, efficient operation of a system and also it plays major role in reducing emission which is necessary for today's environmental activities.

To Sum Up Nozzle rings are the eye of any section in different industries. These play critical roles in the management of air flow, improvement motor performance and release mechanism of energy generation. As a matter of fact, nozzle rings are the linchpin to fueling us with enough power that we need in order for our days just keep going.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

IS

IS