The turbine diffusers help to improve the efficiency of turbines by a considerable margin. The guide tubes, which help in proper airflow and result in better efficiency of the turbine. A closer look at turbine diffusers will reveal how are these so very crucial and what they do act as, making it extremely important for you to understand all the secrets of turbine exhausts.

Why Do Turbine Diffusersmatter?

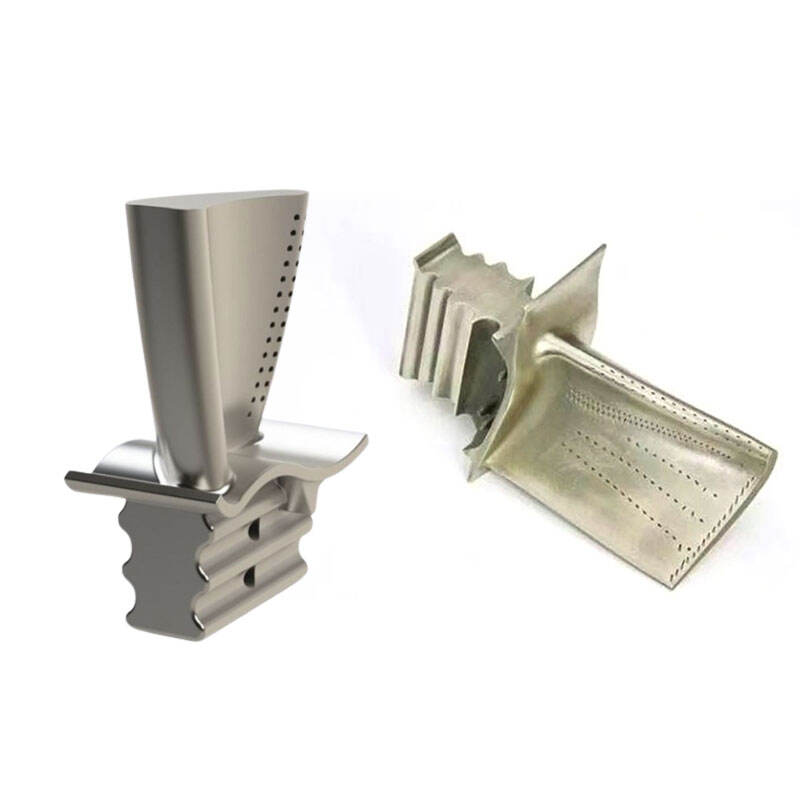

A turbine diffuser looks like a funnel you would use to pour liquid into a small hole. These diffusers are often made out of strong materials like metal or even plastic. Located at the exit of each turbine stage they are used to slow down and direct air in such a way that yields maximum efficiency.

Importance of Diffusers in Turbine Operation

Diffusers cannot be emphasized enough when it comes to the efficient functioning of turbines. If the air flow is not managed, you just mess with the way that controllable turbines work. Engineers spend a significant amount of time and effort in designing such diffusers, specific to various types turbines based on what the latter need inorder for them function at their optimum.

Deconstructing the Diffuser OperationMechanism

The beauty of how diffusers work is the air that flows around gets converted into an organized movement stream. When air enters the diffuser at high velocity and low pressure, its clever shape causes the airflow cross-sectional area to widen leading thus reducing in speed while it simultaneously boosts velocity. Afterward, the diffuser directs this air in right path to be passed with ideal speed and pressure through blades of turbine.

Diffuser Design: Aerodynamic and Material Selection

An important element of effective diffuser design is the use of aerodynamics to ensure that air moves smoothly through them. This is because within the turbine environment, temperatures and pressure are incredibly high therefore much more robust materials such as metal would be selected for this application.

New Diffuser Technologies Rise

As technology develops, engineers are advancing new methods and trends to improve the effectiveness of diffusers. An interesting trend is the use of adjustable flaps which can change airflow angle depending on wind conditions. In addition, new diffuser production methods in 3D printing are being created which allows impossible shapes to be formed so that they function correctly.

The turbine diffusers are very important elements in terms of optimizing the efficiency of a given turbomachinery. Engineers refine diffuser performance through careful design work that balances aerodynamics with robust materials. The current changes in the diffuser turbine designs show potential for improvements to be made with regard as how a turbine operates. The realm of turbines and diffusers is vast, full of intriguing paths to discovery dotted with numerous instances that make you marvel at the engineering behind them.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

IS

IS