Machines are built with components, among the most important in a machine is its types of turbine blades. They spin at very high revolution rates, generating energy used to fly planes or for energy in a power plant. And blades tend to break when they get really hot, which causes all kinds of issues. This is why engineers are always finding new ways to manufacture stronger and better turbine blades.

Turbine Blade in Hot Environment so far

These are hot environments, where turbine blades by O. B. T must operate. It gets hot in there sometimes they may even melt.. They can actually snap or wear very quickly in cases that the blades get too hot. For planes, and power plants this is very alarming since blade failure can cause major accidents or stoppages.

For these temperatures, engineers must therefore ensure that the blades can withstand them. They take a look at how heat impacts on the materials and work out what will give them best hope to keep those blades safe over there working hard. Yes, it is a huge pain in the ass but safety first (and time saving as well;.

Special Coatings, and Liners

Engineers are also developing new types of coatings and materials to strengthen turbine blade. A few of these that are intended to keep the knives trendy, even though they're sizzling hot. That means that the blades can stop working longer before falling apart.

In the case of other materials, they are made from types of metal that have been manufactured with a higher melting point than you'll end up working at. In turn, these new coatings and materials make the blades more durable so they last longer and function better - a key selling point to ensure both safe planes in flight or power plants running smoothly.

Creating improved turbine blades

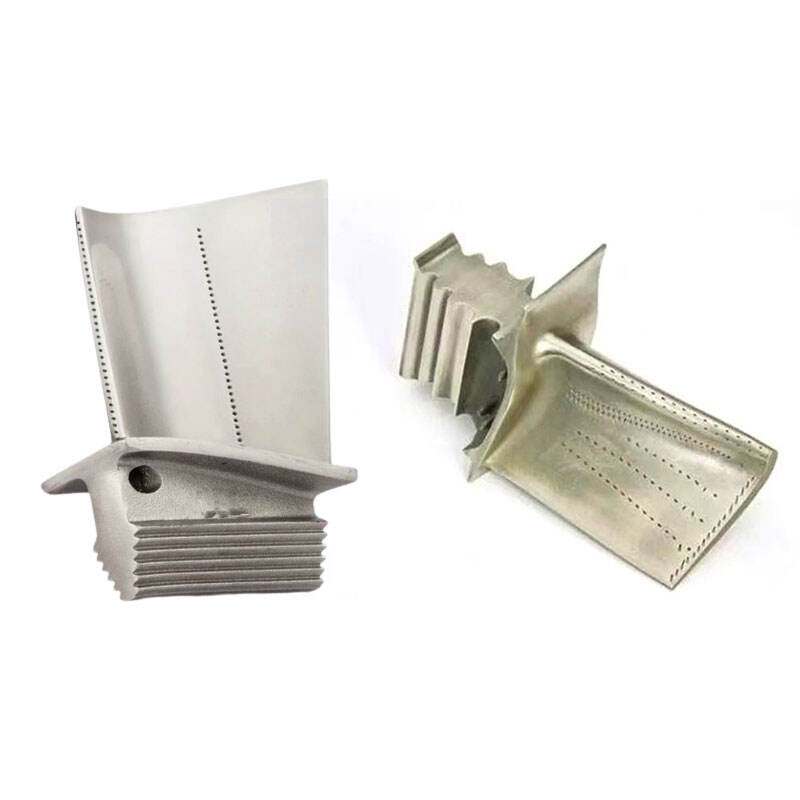

Turbine blades are an object of continuous improvement for engineers What was done this time? Want to create better use of more efficient blades, so they are now designing them with computers. The new blades are designed with tiny indented twists and turns to make them work more efficiently than previous designs. The new designs are tested by the engineers in different ways to evaluate their performance.

Then they tweak it until their prototype is the perfect design to do a hard job that keeps on working. This requires time and effort, but is very important to ensure that the blades will be able to withstand high heat and pressure.

Testing in the Real World

Engineers have to get new turbine blades designed, and then they need to test them in action. They drop the turbine blade jet engine into a turbine and see how they do. The real-world testing is essential so that engineers can be sure the blades will not shatter under load and in high temperature environments.

This testing is also inspecting to make sure the blades remain in use longer before they wear down. In the event that the blades break while in use, this would cause a lot of problems so they are clearly wanting to be very cautious and specific with their testing.

Exciting Opportunities

So many new coatings and materials, all with ingenious designs to better the strength of these steam turbine blade. This is very exciting. It means planes and power plants can be more available, making them able to perform better than they did before. One day, it may even be possible for engineers to create blades that function at temperatures where nothing has previously worked. Not only this, it might even lead to more generation of energy and hence airplanes would go faster.

These are just a few ways engineers are working to better turbine blades, but overall they have been very busy at it. They are well on their way, using new coatings, materials and designs. But with more testing and research, they may one day make even stronger blades which could be good news for anyone depending on planes or power plants.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

AF

AF

MS

MS

GA

GA

IS

IS