In the world of jet engine technology, turbine blade single crystals are essential. These specific crystals are made of a complex mixture of metals such as nickel, cobalts, and chromium. Making these crystals is a long and precise art.

1) Metal Melt - The metals are first melted together into a hot molten mix. It is then cast, or melted down and poured into a mould to set the metal in its initial rough shape. In the next step, this casting goes through heat and a controlled environment which aids in one single crystal structure being formed.

One of those methods is called directional solidification to provide a uniform, strong 3D structure for the crystal. This process uses cooling from bottom to top of the mold gradually concluding with solidified metal across a considerable period A solid crystal emerges from the solution as it cools and grows until attains room temperature size.

When the crystal has been properly developed, it is then cut with special tools designed for that particular purpose to create the final shape. In the final step, every blade is provided with an additional polish and special coatings to withstand extreme heat stress. The blades are then ready to be used in jet engines, where they become one of the limiting factors on how well an engine can perform.

The reason turbine blade single crystals have been used practically exclusively in jet engines is that they don't (or at least can be supposed not to) melt or flow under the pressure and heat conditions we expect them to face. All of these blades see temperatures as high as 2000°C and will spin for tens of thousands of revolutions per minute. They need to be light but strong so as not to delay a van or add extra weight that causes more fuel use, and ideally they should also last for the life of an engine.

Having a unique crystal structure means that the turbine blade single crystals are incredibly strong and resistant to heat. Single crystals such as these have no grain boundaries (unlike polycrystal materials), and any fracture that does occur is not propagated around the blade; this allows them to keep their integrity even in demanding applications.

Single crystals of turbine blade differ from their polycrystalline counterparts in that they have a single crystal structure, chemical composition and properties. But it is one crystal instead of a collection of many crystals with random connections and boundaries. This structural difference has a major effect on the mechanical properties of materials and mineral plasticity.

Single crystal turbine blades also have a chemical composition consisting of nickel, cobalt, chromium and some additives to improve the operational properties at high temperatures as well. Its grain boundary lack instills the material with strength and malleability at high temperatures for reduced failure potential.

The unique attributes of turbine blade single crystals provide many exciting new design opportunities not otherwise possible with polycrystalline materials. These single crystals allow production of complex shaped blades that are essential for ensuring maximum efficiency and performance in modern jet engines by eliminating grain boundaries within the material.

Differences in turbine blade single crystals also allow for advanced coatings and surface treatments to be applied, enhancing properties of the material. These coatings not only improve wear and friction behavior, but also reduce heat losses through the blade material itself, which would benefit in a general lift of operation.

The evolution of turbine blade single crystals is a great example to show how materials science starts new technological ages. Techniques such as directional solidification and crystal growth have allowed engineers to create plastics with improved mechanical or thermal properties. The jet engine is among the prime examples of how these materials have been able to highlight improvements in performance, efficiency and safety.

With the continuing evolution of materials science, one would expect improvements from turbine blade single crystal technology down the road. New alloys and coatings are being developed that will increase heat resistance and mechanical strength, which means the jet engines can run at even higher temperatures and pressures. These developments will not only increase engine efficiency and power, but also help to cut down on fuel consumption and emissions.

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet turbine blade single crystal, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

We adhere to the strictest guidelines for quality control to ensure the turbine blade single crystal and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.

Our complete customer service package includes pre-sales consultation technical support and after-sales assistance to ensure our customers have the best possible experience When it comes to the pre-sales phase our experienced team will understand the customer's needs in detail and provide the most suitable suggestions and solutions In terms of technical support we offer full guidance from product selection until installation and commissioning to ensure that our customers use our products efficiently When it comes to after-sales service we have developed an turbine blade single crystal service system that can respond swiftly to customer issues as well as needs and provide quick and effective solutions We want to create long-lasting relationships with our customers and gain their trust and appreciation by offering high-quality services

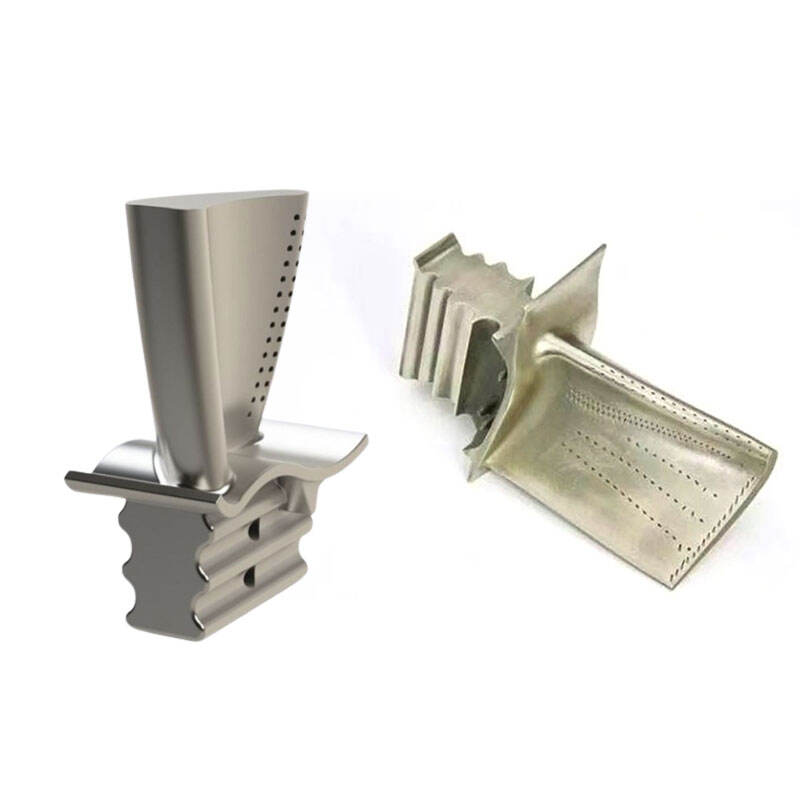

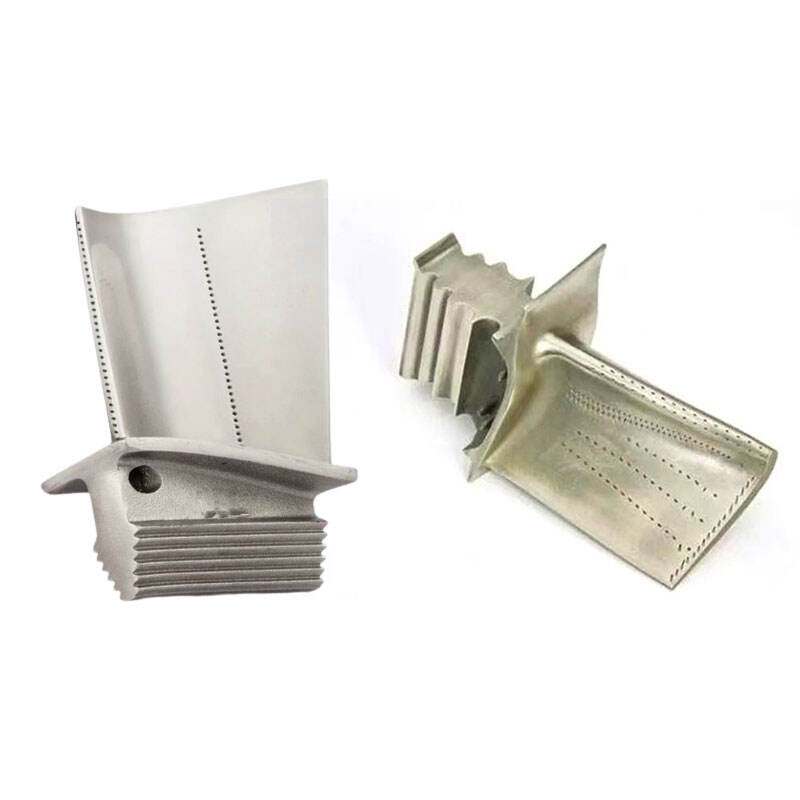

Our company is able create highly precise and reliable turbine blade single crystal by using casting, forging and CNC machine processes. Casting allows us to make parts with complicated designs, strong and long-lasting. Forging gives parts a higher mechanical property and durability. CNC technology for machining, on other hand, ensures an extremely high level of precision and consistency in each component, thus reducing the risk of manufacturing errors and resulting in substandard products. Our technical staff is constantly striving to improve technological innovation and process improvements to ensure that our products remain at the leading edge of industry technology. We're committed to meeting the demands of our customers for high-performance turbine parts through constant technological advancement.