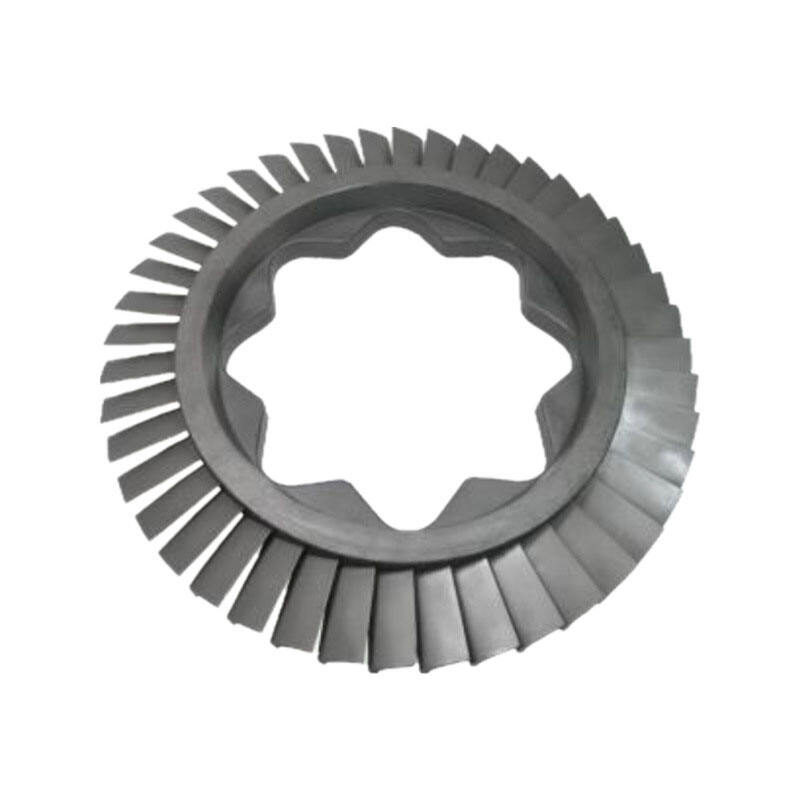

A car is a difficult concept that goes faster, and the engine parts of a turbocharger make it work better. It takes air and really forces more of it into the engine to help create power. A nozzle ring A very important component of a turbocharger. The nozzle ring is the part that controls which way air flows through your turbo, and this has a huge impact on how it performs. This round ring between two wheels, the turbine wheel and compressor wheel is called a Turbine race. The turbine wheel is powered by the gases from the engine exhaust, while at its side sits a compressor wheel which helps cram air into the engine. The primary function of the nozzle ring is to take exhaust gases from the engine and lead them into turbine wheel, as well for controlling airflow that goes in compressor wheel.

The design of the nozzle ring has a lot to do with how well he Turbocharger works. Nozzle RingSize And ShapeDepending how much air will able to pass through the Nozzlering When you have a larger nozzle ring, passing more exhaust gases in through the turbine wheel. This helps to get the turbocharger functioning quicker and more efficiently. A more efficient turbo = the engine can make more power without using additional fuel. Meanwhile, a smaller nozzle ring will have the effect of spooling up the turbocharger faster. That simply means that the car will be able to accelerate quicker when you step on the gas. But a smaller nozzle ring will starve the turbocharger for air and this won't always give top performance. To have a turbocharger perform at its absolute best, the right size and design of nozzle ring must be used.

The best turbocharger design goes to waste if the nozzle ring is not designed to provide high efficiency; as such other part materials used in hand with outstanding quality. Nozzle rings are typically made from one of the three materials - cast iron, stainless steel or tungsten carbide. Typically this material will be cast iron and not nearly as strong or durable as the other types of materials. It does tend to wear out in higher temperatures and under pressure. The Advantages of Stainless Steel As a newer technology, stainless steel is the material of choice in many modern turbochargers today since it is strong enough to resist rust and able to keep its shape even when hot. This makes it a smart choice for decently priced cars.ReadLine The Tungsten carbide is the most robust of these materials, which makes it preferable for high performance applications like in racing cars or on a high power car turbochargers. There are many advantages and disadvantages of each material, so the choice largely influences turbocharger efficiency and lifespan.

Blockage of nozzle rings - Nozzle rings could become blocked due to dirt and trash over time. While the turbocharger itself can clean out and get rid of this carbon layer, it wears off after excessive build-up which then starts to reduce the airflow going through some parts that in turn requires more work for proper function. This means that when the turbocharger has to work harder it might consume more fuel which can decrease the engines performance Regular cleaning of the nozzle ring is essential for rectifying this issue. If there is dirt or debris that has collected on the fan, clean it by brushing gently with a soft brush and / or use compressed air to blow all of the dust away. The nozzle ring can also wear out or be damaged over time. This wear and tear may be a reason why the turbo is not operating as it should. If the nozzle ring is damaged, it will need to be replaced with a new one in order for the turbocharger to continue functioning well and reliably.

A working nozzle ring is one of the most important components if you want to make a car that will perform better overall. The nozzle ring, during the regular operation of your car engine enabled you with a better performance in terms of speed limit reached and also amount power output as well through ways that it manages how fast can go out or slow down. Which is to say, don't you hate it when you floor the throttle and a second later all that happens is... well even in normal cars faster gear changes mean more instant acceleration. In case the nozzle ring is not so good, this can make a vehicle run slow or lose acceleration and even could be having increasing fuel consumption. This negatively impact the performance and can increase cost at pump as well. Frequent cleaning or changing of the nozzle ring can ensure that your turbocharger is operating effectively to obtain the performance you require from car. Drivers get to experience a smoother, more powerful driver when they look after the nozzle ring.

We adhere to the strictest guidelines for quality control to ensure the nozzle ring in turbocharger and reliability each component. Every step of the production process is monitored for quality starting from the purchase of raw materials all the way to the final test of the product. To ensure that the quality of our products are continuously improved, we conduct regular audits and improvement. We want to win the trust of our customers and their long-term cooperation by providing high-quality products.

Our company has the ability to produce highly accurate and consistent turbine components by using casting, forging and CNC nozzle ring in turbocharger. The casting process permits us to produce parts with complex shapes and high strength, whereas the forging process gives the parts better mechanical properties and longer lasting. CNC machine technology, on the contrary, guarantees an extremely high level of precision and consistency in each component, thus reducing the risk of errors and substandard products. Our skilled technical team is always striving to improve technological innovation and process improvements in order to ensure our products are at the cutting-edge of technology in the industry. We're committed to meeting our customers' needs for turbine components that are high-performance through constant technological advancement.

Our company provides nozzle ring in turbocharger, and we is able to manufacture turbine parts from many high-temperature aluminum alloys in order to satisfy the demands of customers. Our flexible production flow and advanced technology for processing and our ability to satisfy particular requirements, like size and shape, as well as performance will allow us to meet any need. We work closely with customers to fully comprehend their requirements and applications scenarios and provide them with expert assistance and suggestions. We have a broad range of materials and processing capabilities to meet the special demands of various industries and applications. Our clients can improve their competitiveness on the market by offering customized services that optimize performance and reduce cost.

Our customer support is comprehensive and includesnozzle ring in turbocharger, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.