Beautiful in jets, plane on moster fast They move so quickly that a car or train cannot even race it, they have engines with power. These components work in unison allowing a plane to ascend through the atmosphere and withstand make great heights finally-all thanks to these jet engines. Compressor Blade This is a compressor blade. Well then, what purpose do those blades actually serve and why are they so important to a jet engine?

Compressor Blade- A curved piece of metal located inside the engine. It rotates very fast, more than you can even think! What actually causes the rotation is, then it becomes too inefficient in drawing air from outside of the plane. This air is then tightly squeezed together and combined with fuel, resulting in an enormous explosion within the engine. All this force results in one gigantic boom, and that is what has the engine propelling itself faster! How fast they can fly in the sky (in smth like that GMT when engine is running at higher RPM)

Engineers were the brains that made planes fly faster and safer for everyone, Mr Walker said Thankfully, it looks like they've hit their deadlines on the compressor blades to help that important mission along. Fuel characteristics have transformed and more power compressors blades which can be molded from strong, lightweight compounds. As a result, this allows for the engine to be fuel stationary all while giving long range capability in flight. In another intriguing step engineers are contouring the blades optimising aerodynamics. These are an airfoil blade, in other words the shape of this particular piece helps guide these blades so that even more power can be delivered to push you way up there and get accelerating awesome fast.

The compressor blades are one of the more important parts to make a jet engine fly safely and efficiently. They will be spinning at full throttle while you work with the engine for over a hundred years of an average life. It is a wear and tear material or it gets destroyed if they are not durable. It can have catastrophic consequences if one of those blades breaks at high power operations...even killing the airplane - not good. Which is why it needs to be all the more important that these blades are as tough and dependable as possible by using only top-of-the-line materials/ manufacturing technologies.

In the case of a jet engine, one set that plays an especially important role are those compressor blades. They help the engine to suck in air, compress it and fabricate with fuel for a resultant explosion that propels the aeroplane forward. The engine would never generate adequate power without these blades and it will be powerless in lifting the plane up into air. For the pilots, and also for the engineers they have on it with his life that is awaiting - hence this needs to be kept in a good hand as well so should all compressor blades remain intact.

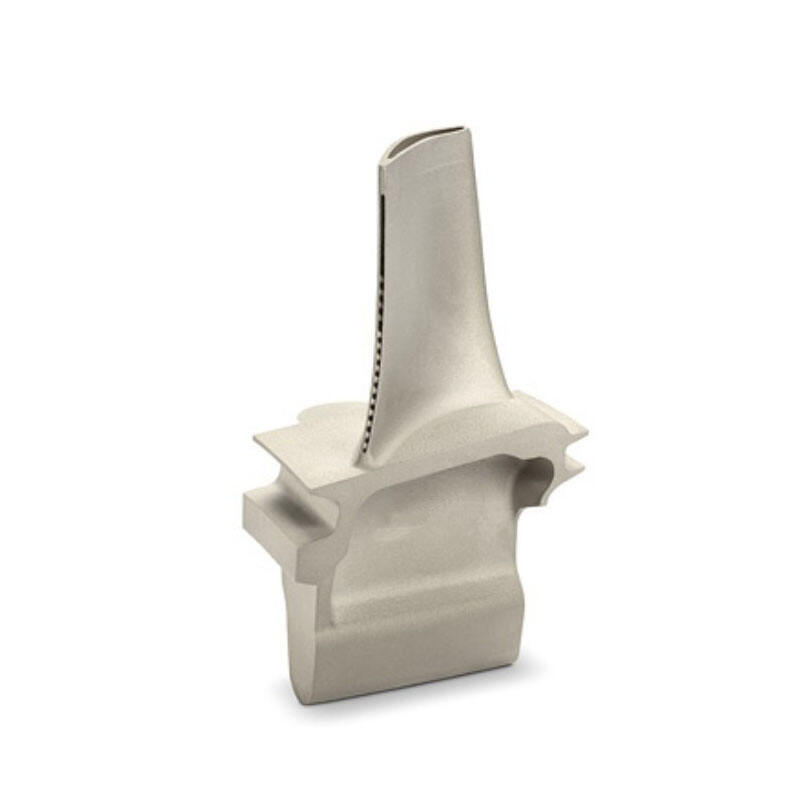

The efficiency in this compressor blade is maximum, which makes definitely work great It has a one of its kind shape which goes narrower from the base and then widens slightly upwards towards the end. That unique front design also streamlined the passage of air over the blade and further aids in getting it through for force to drive engine. The blades are also covered in a compound that lets them survive the high of heat and pressure above they take during flight. This is to prevent the blades from becoming excessively worn or otherwise damaged in high load conditions your motor.

We adhere to the strictest standards of quality control to ensure the reliability and performance of each component Quality control is conducted throughout the entire process of production from the purchase of raw materials to the testing of the jet engine: compressor blades In order to ensure that our product's quality are constantly improved we perform regular audits and improvements Our aim is to win the trust and continue to work with of our customers through providing quality products that are of the highest standard and to be a leader in the industry

We offer a comprehensive customer service that includes pre-sales consultation as well as technical support and after-sales assistance so that our customers have the most pleasant experience In the pre-sales stage our experienced team will understand the customer's needs in detail and provide the most appropriate suggestions for products and solutions For technical support we offer full guidance from product selection to installation and commissioning to ensure that our customers use our products with ease We have developed an after-sales program that enables us to quickly respond to customer concerns and issues and to provide effective and timely solutions We are determined to develop long-term relationships with our clients and jet engine: compressor blades their trust and satisfaction through offering high-quality services

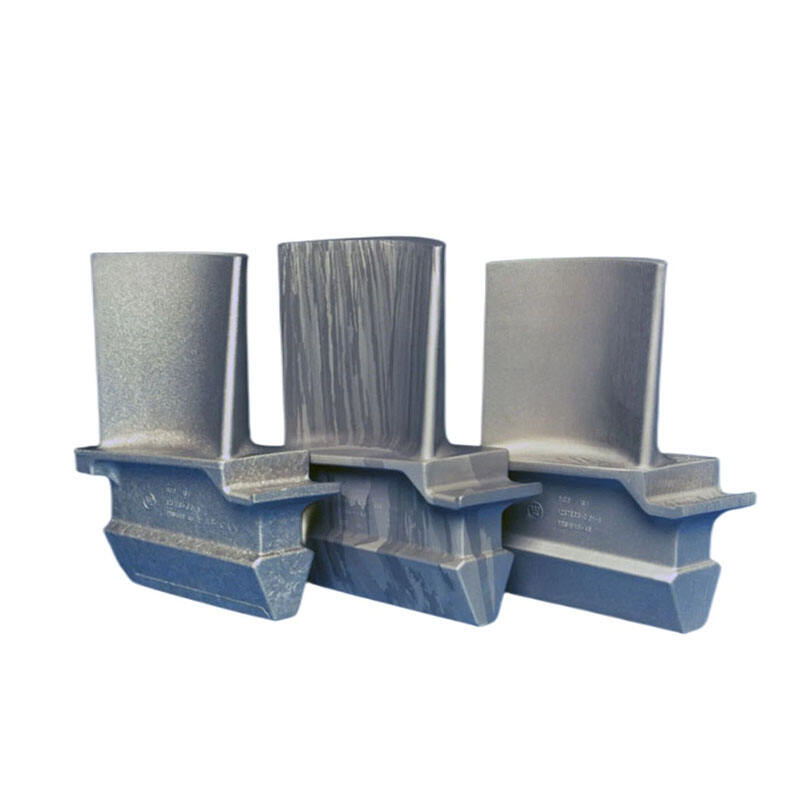

We are able to create turbine components with high accuracy and consistent quality through CNC machining, casting and forging processes. Casting allows us to create parts with complex shapes, high strength and long-lasting. Forging can give parts a more durable and superior mechanical property. CNC jet engine: compressor blades technology, on other hand, ensures the highest precision and accuracy of each piece, minimizing mistakes and ensuring that the product is of a high standard. Our highly skilled technical team is continuously developing technological advancements and process optimizations in order to keep our products at the cutting-edge of technology in the industry. Our commitment is to meet the needs of our customers for components that are high-performance by developing technology continuously.

Our company offers a variety of custom-designed services and is able to manufacture turbine parts from various high-temperature alloys to meet the requirements of our customers. Our jet engine: compressor blades along with our advanced process technology and our capability to meet specific requirements, such as size shape, performance, or shape can allow us to meet every need. We work closely with our customers to understand their specific needs and application situations and offer expert technical guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements to the application allow us meet the requirements of various industries and application. With our customized services, we assist our customers in optimizing their the performance of their products and reduce costs, and improve market competitiveness.