In a way, compressor blades are like wizard wings for the gargantuan machinery. In factories to make the things like cars and bikes we actually use. The blades ensure the conclusions with a very progressive and efficient working process

Compressor blade designers work in cooperation with engineers and scientists who develop the blades, meaning it is not exactly survival of fittest as one might think. This includes how the blade is shaped on a computer before being forged from exotic materials, then attached to a disk that just so happens to work with an equally complex compressor system.

When it comes to industrial machine work, compressor blades are must-have. Those blades set other things in motion, by either moving air or gas / liquid around the machine mentioned. These blades are expected to meet the high-pressure and stress conditions demanded by the machine. If the compressor blades are not being made on time first then everything else stops and that impacts driving critical equipment.

New Age Technology of Compressor Blade Shapes to Construct Improved Machines

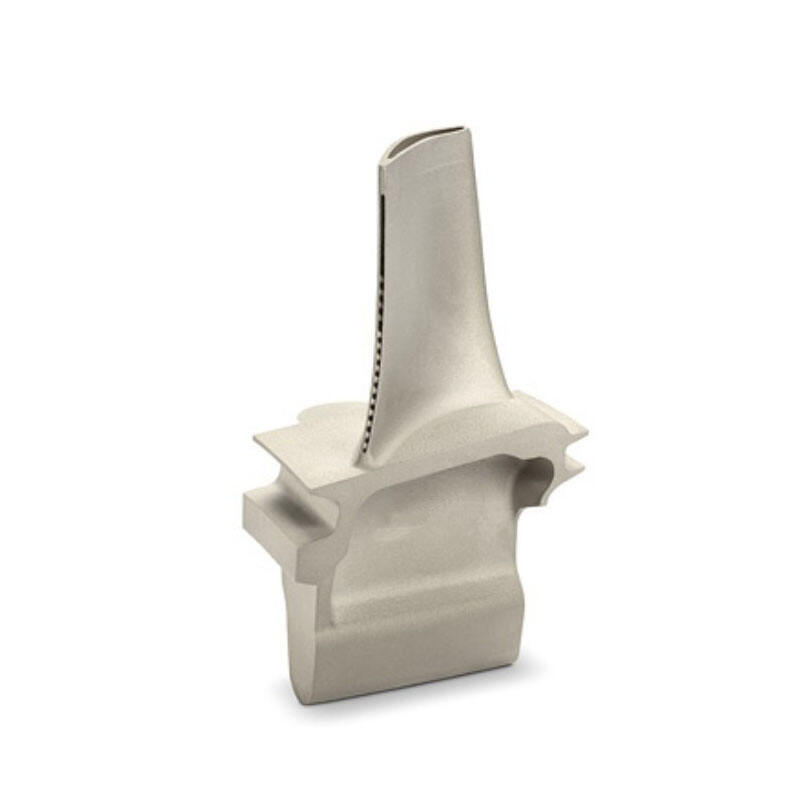

The shape of the blades used in compressor is a special developed one to provide an excellent performance. In this way the highly skilled engineer brings their skill set to bear on designing individual blades of a machine which direct air flow (or gas). Furthermore, there are external variables to be considered like noise and vibration which can affect the performance of a particular machine.

Compressor blades traditionally have been manufactured using materials having features like steel or titanium. Yet today with the advancement in technology, scientists are manufacturing more recent new materials which can be both stronger still yet lighter on body weight. More operator friendly newer materials are developed to work with machines efficiently. Or tune properties like ultra-high high-temperature resistance or some corrosion characteristics in composites.

Compressor Blade Maintenance Some of the most crucial components in an industrial gas turbine are its compressor blades, and they should be well looked after if operators wish to extract many years of effective service from them. Blade maintenance: Retaining clean, damage free and oiled blades is vital for making sure they function properly. These compressor blades can save thousands of dollars through the life with its authentic replacement costs and also ensure that your factories or any industrial set up experience minimum downtime.

This is why the compressor blades are important aspects of industrial equipment and serve as a leading force in driving countless actions we execute every day. This dedication is found in the meticulous work that engineers and scientist perform as they design, optimize and improve blades to gain peak efficiency for their use which drives their reliability. Maintenance can ensure that those compressor blades remain in their proper form, which is what produces such a discernible impact on the world.

Our company adheres to strict quality standards to ensure the highest quality and the reliability of every component Quality control is carried out throughout the entire process of production from the acquisition of raw materials to the testing of the final product We also perform regular quality compressor blade and adjustments to ensure constant improvements in product quality Our goal is to win the trust and long-term cooperation of our clients by offering high-quality products and to become a leader in the industry

Our company offers customized services and is able to fabricate turbine components from many different high temperature alloys based on customer specifications. Our flexible production flow along with our advanced process technology and our capability to meet compressor blade, such as size and shape, as well as performance can allow us to meet any requirement. We work closely with clients to comprehend their needs and the potential scenarios for their applications, and then give them professional guidance and solutions. Our wide range of products processing capabilities, processing capabilities, and specific requirements for applications allow us to fulfill the particular requirements of various industries and application. With our customized services, we help our customers optimize efficiency and costs of their products, and improve market competitiveness.

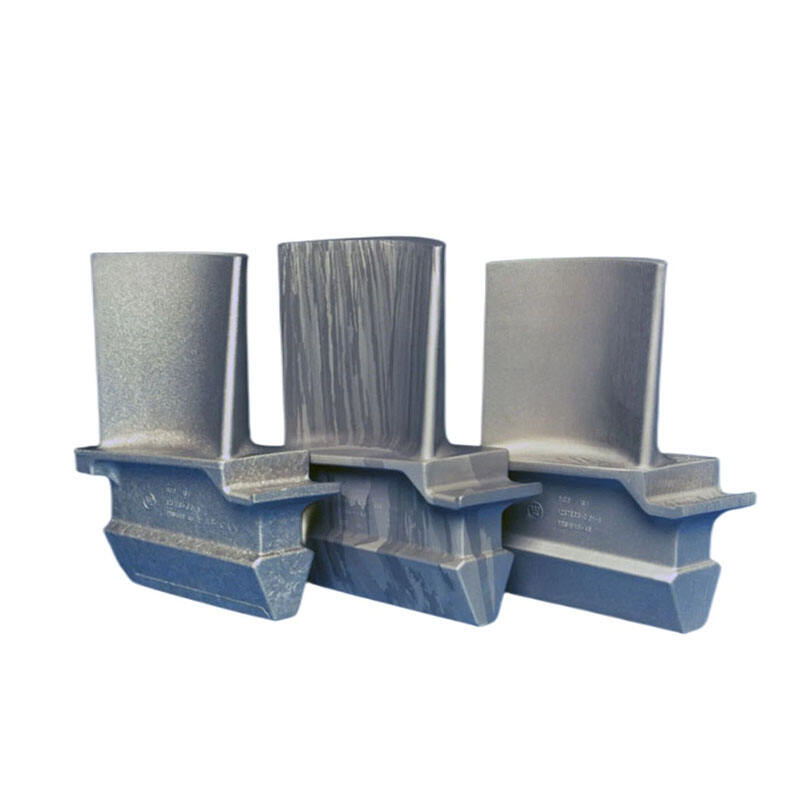

We are able of producing turbine components with high accuracy and consistency through CNC machining, casting and forging processes. The casting process permits us to create parts with intricate shapes and strong strength, while the process of forging provides parts higher mechanical properties and longer lasting. CNC machining, on the contrary it provides superior precision and consistent quality for every part. This reduces errors and lower quality products. Our skilled technical team is always working on technological innovations and process optimizations in order to compressor blade that our products remain at cutting-edge of technology in the industry. Our goal is to satisfy the needs of our customers for high-performance parts by constantly advancing technology continuously.

Our customer support is comprehensive and includescompressor blade, technical support, and after-sales services to ensure that our customers get the best experience possible. Our team of experts will evaluate the requirements of the customer and offer appropriate product solutions and suggestions. We provide technical support starting with the selection of products to installation and commissioning. This ensures that our clients are able to use our products without any issues. We have a well-developed after-sales process that allows us to swiftly respond to issues and needs of customers, and to provide effective and prompt solutions. We are determined to develop long-term relationships with our clients and gain their trust and respect by offering high-quality services.