Stellite 250 is a cobalt-chromium-iron heat-resistant alloy with excellent resistance to thermal shock, oxidation and hot corrosion. Stellite 250 is suitable for various uses in heat treatment furnaces or metallurgical industry furnaces such as roasters and smelting furnaces. Potential applications include thermowells, tuyeres, lances, gaskets, grates, pallets, skids for slab reheat furnaces, gas and pulverized coal burners, discharge rollers and channels, radiant tube supports and with slag and ore certain parts in contact. Stellite 250 is designed to resist carburization and vulcanization of furnace components and is machinable.

Stellite™ 250 Alloy

Nominal Composition (Mass %) and Physical Properties

| Co | Cr | Fe | C | Si | Others | Hardness | Density (deposit) | Melting Range |

| Base | 28 | 20 | 0.1 | 1.0 | Mn | 18-29 HRC | 8.05 g/cm30.291 lb/in3 | 1380-1395ºC2515-2540ºF |

Stellite cobalt-based alloys consist of complex carbides in the alloy matrix. They are resistant to abrasion, abrasion and corrosion and retain these properties at high temperatures. Its excellent wear resistance is mainly attributed to the unique inherent properties of the hard carbide phase dispersed in the CoCr alloy matrix.

We can customize products for you based on the 2D, 3D drawings or samples you provide

product

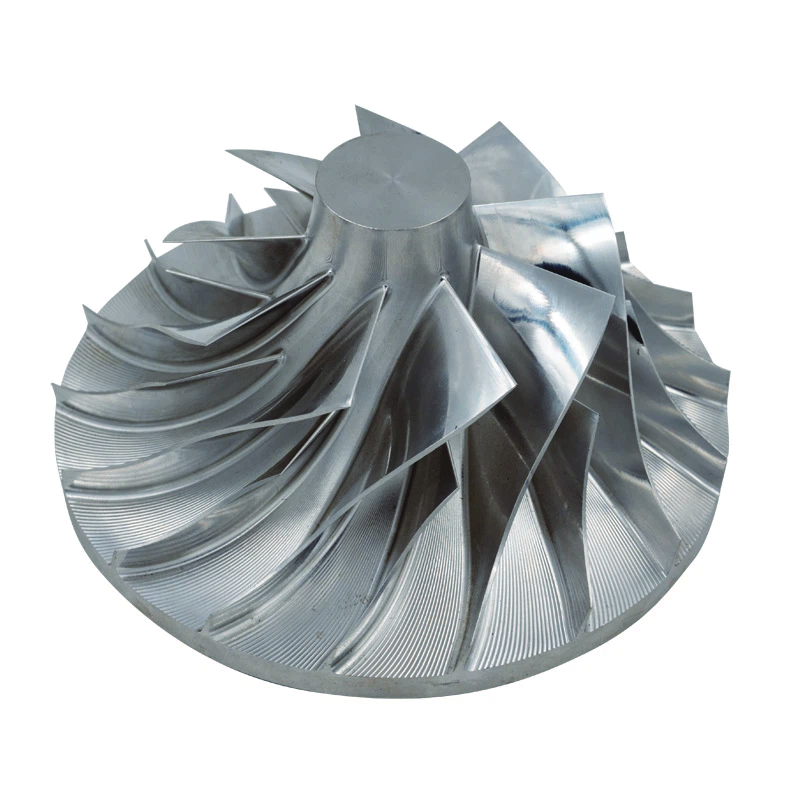

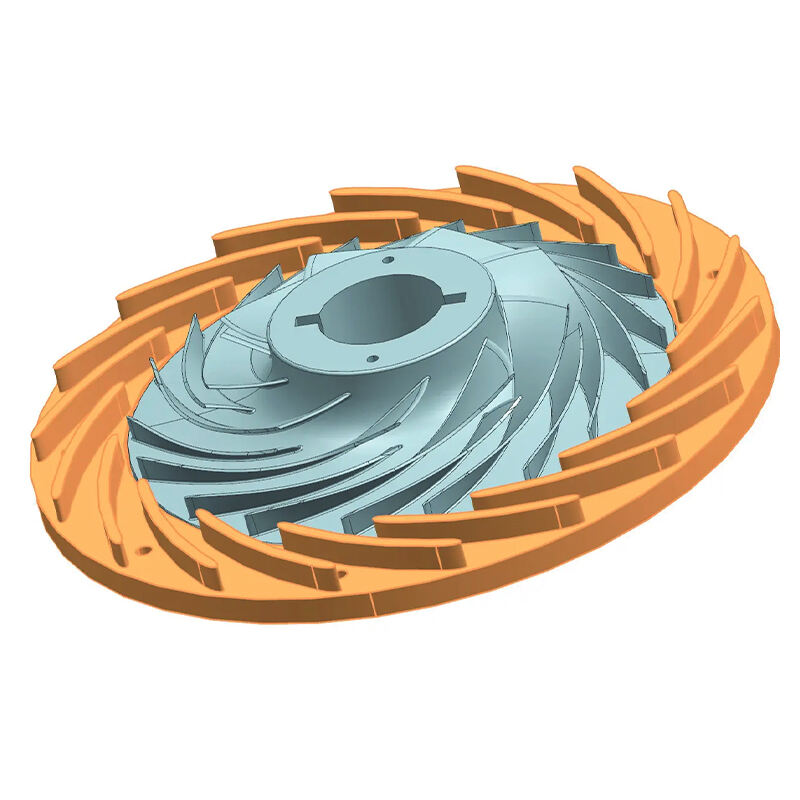

turbine wheel

turbine blade

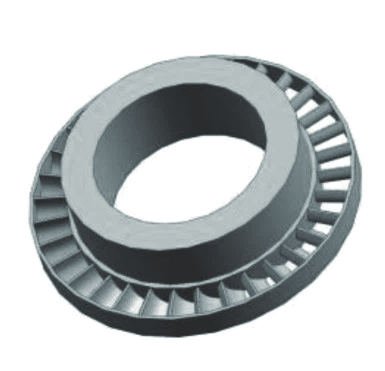

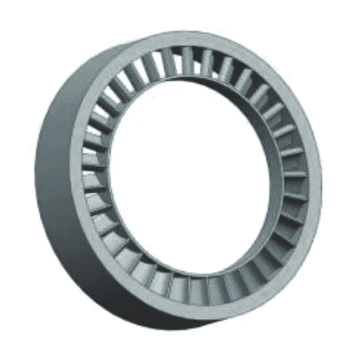

nozzle ring

compressor blade

guide vanes

diffuser

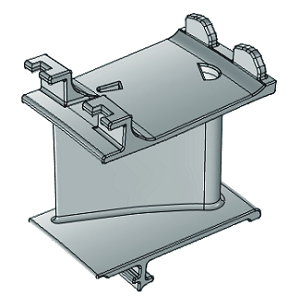

Segment

Turbine Rotor

Turbine Stator

Stellite sheet

Stellite pipe

Stellite rod

Stellite bolt and nut

Stellite Fasteners

Stellite wire

spring

According to drawings or samples

Stellite alloys are a group of cobalt-chromium alloys known for their exceptional wear resistance, high temperature performance and corrosion resistance. Here's an overview of Stellite:

Composition:

Stellite alloys are primarily composed of cobalt (about 50-65%) and chromium (about 25-30%), with varying proportions of tungsten, carbon and other elements depending on the grade. These alloying elements give Stellite alloys a unique combination of properties.

Wear Resistance:

Stellite alloys are known for their excellent wear resistance, making them suitable for applications where components are subject to abrasive wear, erosion and sliding contact. They are typically used in high-wear environments such as cutting tools, saw teeth, valve seats, and pump components.

High Temperature Performance:

Stellite retains its mechanical properties at high temperatures, allowing it to withstand high temperatures without significant loss of strength or hardness. This makes Stellite alloys suitable for high-temperature applications such as gas turbine components, furnace components and exhaust valves.

Corrosion Resistance:

Stellite alloys exhibit good corrosion resistance in a variety of environments, including acidic and alkaline solutions, as well as high-temperature gases and molten salts. This corrosion resistance makes Stellite alloys suitable for use in chemical processing, marine engineering, and oil and gas production.

Versatility:

Stellite alloys are available in a variety of grades and forms, including powders for thermal spray coatings, castings and forgings such as rods and plates. This versatility allows the selection of the most appropriate grade and form of Stellite alloy for a specific application.

Applications:

Stellite alloys are widely used in aerospace, automotive, oil and gas, power generation and manufacturing industries. They are widely used in components requiring wear resistance, high temperature performance and corrosion resistance.

Aerospace field

Automobile and motorcycle manufacturing

Chemical industry

Marine engineering

Our professional sales team are waiting for your consultation.