Nimonic is a family of high-temperature alloys known for their excellent performance in high temperatures, pressures and corrosive environments. These alloys are primarily composed of nickel and chromium, and often also contain elements such as cobalt, molybdenum, iron, titanium, and aluminum. Nimonic alloys have excellent oxidation resistance, heat resistance, corrosion resistance and mechanical properties, and are suitable for various high-temperature applications, such as aerospace engines, spacecraft parts, gas turbines, nuclear reactors and chemical equipment.

Nimonic alloys are usually named after the main elements in their composition, such as Nimonic 75, Nimonic 80A, Nimonic 90, Nimonic 105,etc. Each Nimonic alloy has specific properties and uses:

Nimonic 75:

It has good heat resistance and is widely used in high-temperature parts in aircraft engines and gas turbines.

Nimonic 80A:

It has excellent oxidation resistance and heat resistance, and is suitable for parts manufacturing in high temperature and high pressure environments.

Nimonic 90:

Offers high strength and creep resistance and is commonly used for high-temperature parts in aerospace and gas turbines.

Nimonic 263:

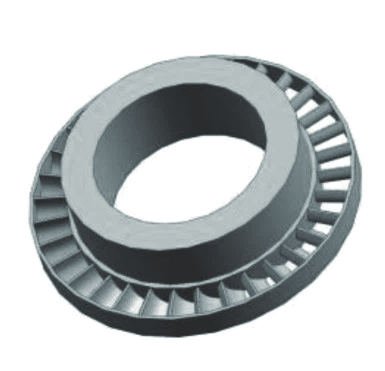

It has excellent oxidation resistance and heat resistance, and is suitable for manufacturing parts under high temperature and high pressure conditions, such as turbine blades and nozzle guide rings.

Nimonic 105:

Contains elements such as chromium, cobalt, iron, molybdenum, aluminum and titanium. It has excellent high-temperature strength and oxidation resistance and is suitable for aerospace and gas turbine fields.

product

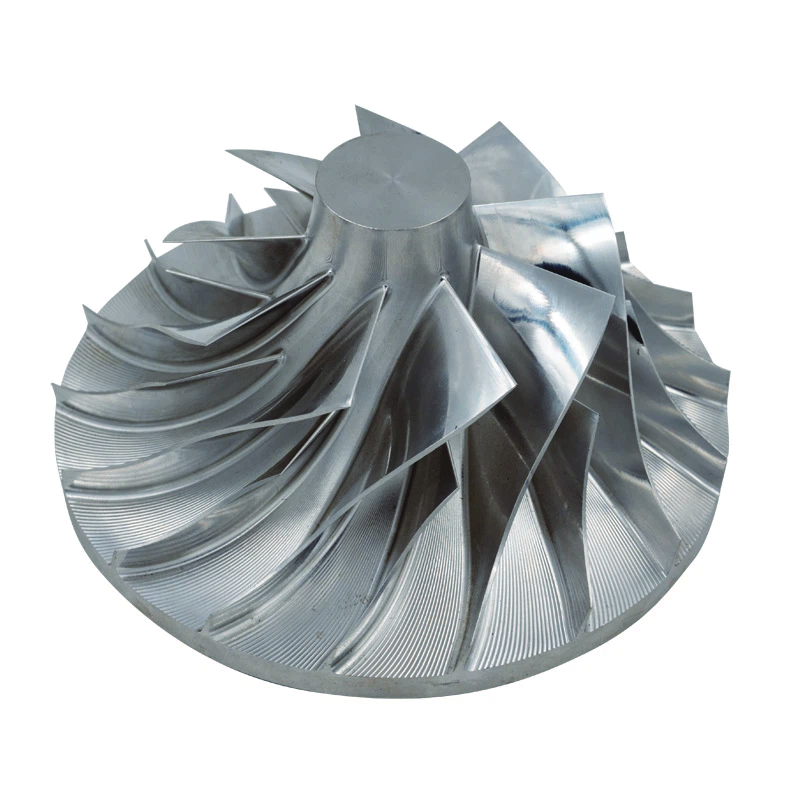

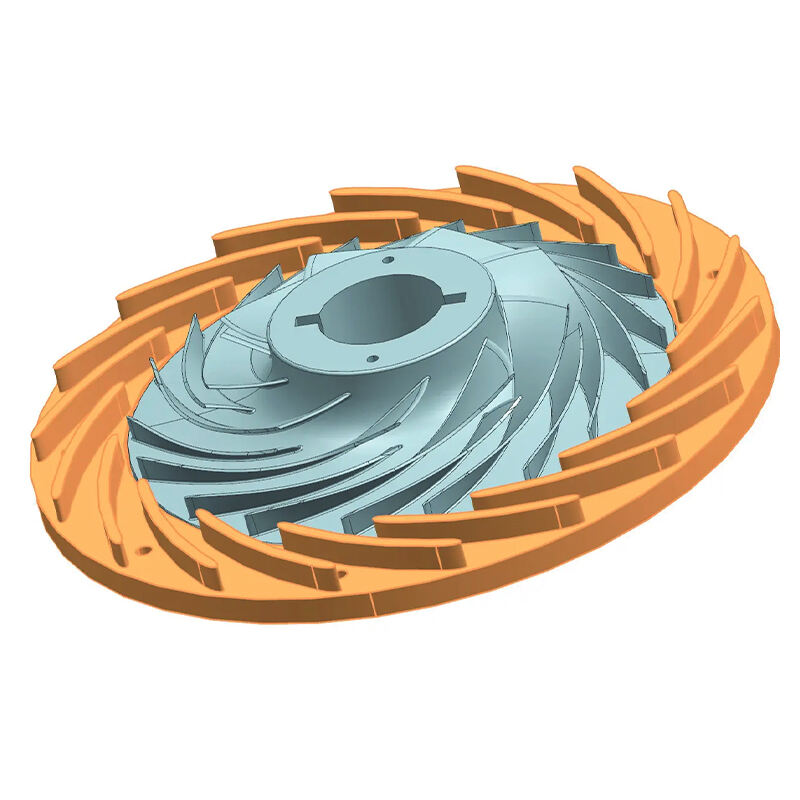

turbine wheel

turbine blade

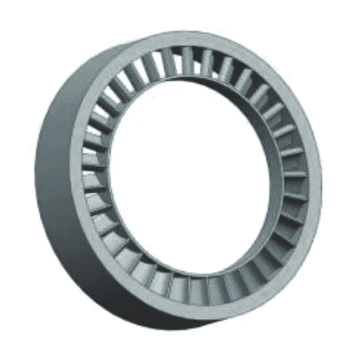

nozzle ring

compressor blade

guide vanes

diffuser

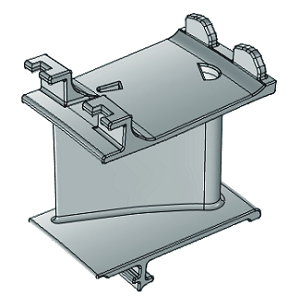

Segment

Turbine Rotor

Turbine Stator

Nimonic sheet

Nimonic pipe

Nimonic rod

Nimonic bolt and nut

Nimonic Fasteners

Nimonic wire

spring

According to drawings or samples

Nimonic alloy is widely used in many high temperature and high pressure industrial fields due to its excellent high temperature strength, oxidation resistance and corrosion resistance. For example:

Aerospace field:

Nimonic alloys are widely used in high-temperature components such as aerospace engines, aerospace components, jet blades, turbine blades, high-temperature nozzles, and gas turbines to cope with extreme working environments and high-temperature and high-pressure conditions.

Energy field:

In the energy industry, Nimonic alloys are commonly used in equipment such as gas turbines, high-temperature components in nuclear reactors, gas burners and furnaces, as well as high-temperature reactors and heating devices in the petrochemical industry.

Chemical industry:

Because Nimonic alloy has excellent corrosion resistance, it is often used in chemical equipment, such as reactors, distillation towers, pipes, valves, etc., especially in working environments under high temperature, high pressure and corrosive media.

Automotive industry:

In the automotive industry, Nimonic alloys are used to manufacture high-performance engine components, such as turbochargers, exhaust valves, cylinder heads and cylinder walls, etc., to improve engine efficiency and performance.

Medical equipment:

Nimonic alloy is also used to manufacture high-temperature components in medical equipment, such as high-temperature sterilizers, medical lasers, X-ray equipment, etc., to cope with the needs of medical equipment under high-temperature working conditions.

Aerospace field

Automobile and motorcycle manufacturing

Chemical industry

Marine engineering

Our professional sales team are waiting for your consultation.