Inconel718 alloy has good comprehensive properties in the temperature range of -253 ~ 700°C. The yield strength below 650°C ranks first among deformed high-temperature alloys and has good fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, and good Due to its processing performance, welding performance and long-term structural stability, it can manufacture various parts with complex shapes. It has been widely used in the aerospace, nuclear energy and petroleum industries within the above temperature range.

Another characteristic of this alloy is that the alloy structure is particularly sensitive to the thermal processing process. By mastering the phase precipitation and dissolution rules in the alloy and the relationship between the structure and process performance, reasonable and feasible process procedures can be formulated for different use requirements. A variety of parts are available to meet different strength levels and usage requirements. The varieties supplied include forgings, forged bars, rolled bars, cold-rolled bars, round cakes, rings, plates, strips, wire tubes, etc. It can be made into discs, ring blades, shafts, fasteners and elastic elements, plate structural parts, casings and other parts for long-term use in aviation.

Main features:

(1) Ease of processing

(2) High tensile strength, fatigue strength, creep resistance and fracture strength at 700°C

(3) High oxidation resistance at 1000°C

(4) Stable chemical properties at low temperatures

(5) Good welding performance.

Application fields of Inconel718: Due to its high temperature strength, excellent corrosion resistance and easy processability at 700C, it can be widely used in various high-demand situations.

(1)Steam turbine

(2)Liquid fuel rocket

(3)Cryogenic engineering

(4)Acidic environment

(5) Nuclear engineering

product

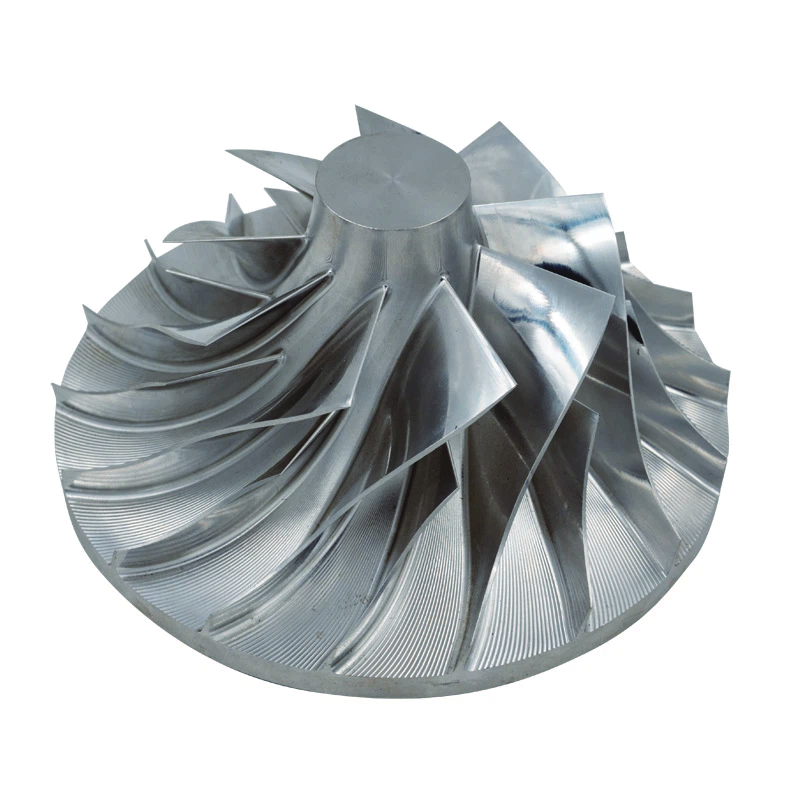

turbine wheel

turbine blade

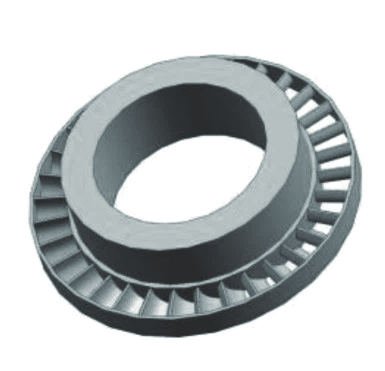

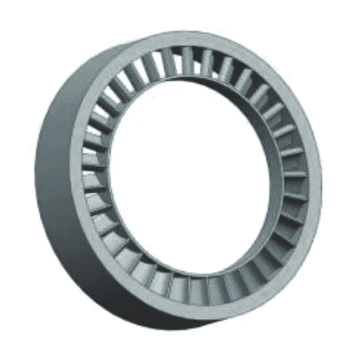

nozzle ring

compressor blade

guide vanes

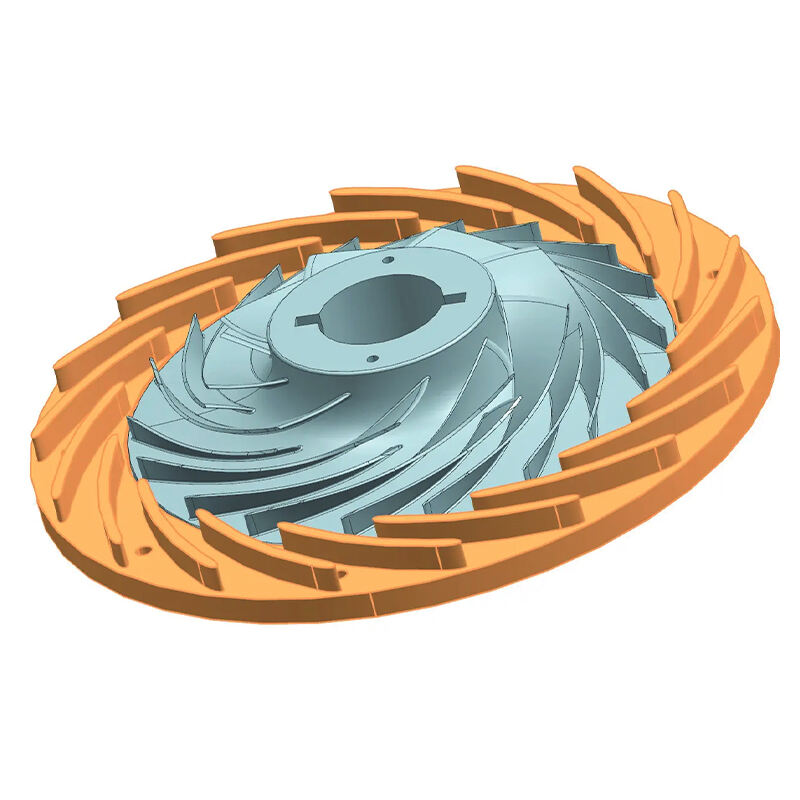

diffuser

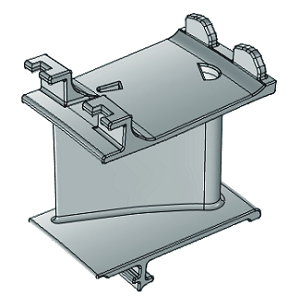

Segment

Turbine Rotor

Turbine Stator

Inconel sheet

Inconel pipe

Inconel rod

Inconel bolt and nut

Inconel Fasteners

Inconel wire

spring

According to drawings or samples

Inconel is a series of nickel-based high-temperature alloys known for its excellent high temperature resistance, corrosion resistance and oxidation resistance. Here are some key points about Inconel:

High Temperature Resistance:

Inconel retains its strength and integrity at high temperatures, making it ideal for use in high-temperature environments such as gas turbines, jet engines, and industrial heating applications.

Corrosion Resistance:

Inconel exhibits excellent corrosion resistance even in harsh environments such as seawater, acidic solutions and chemical processing plants. This corrosion resistance is due to the formation of a protective oxide layer on the surface of the material.

Strength and toughness:

Inconel has high strength and toughness, allowing it to withstand extreme mechanical stress and strain in demanding applications.

Versatility:

Inconel is highly versatile and can be processed into a variety of forms, including sheet, plate, rod, wire and tube, to suit different applications.

Alloying Elements:

Inconel typically contains nickel as the base metal, along with chromium, iron, and other elements such as molybdenum, cobalt, and niobium. These alloying elements give Inconel a unique combination of properties.

In summary, Inconel is a highly engineered material designed to operate in the most demanding environments where high temperatures, corrosion, and mechanical stress are prevalent. Their unique combination of properties makes them indispensable in critical applications across industries.

Aerospace field

Automobile and motorcycle manufacturing

Chemical industry

Marine engineering

Our professional sales team are waiting for your consultation.