Hastelloy X (N06002) Hastelloy And creep strength, cold and hot working formability and welding performance are good. It is used to manufacture combustion chamber components and other high-temperature components of aeroengines. It can be used under 900℃ for a long time and the short-term working temperature can reach 1080℃. The main varieties supplied are plates, strips, pipes, bars, forgings, rings and precision castings.

Hastelloy X chemical composition

| C≤ | Si≤ | Mn≤ | P≤ | S≤ | Cr≥ | Ni≥ | Mo≥ | Cu≤ |

| 0.05-0.15 | 1.00 | 1.00 | 0.025 | 0.015 | 20.5-23.0 | 余量 | 8.0-10.0 | 0.50 |

| Others | N≤ | Al≤ | Ti≤ | Fe≤ | Co≤ | V≤ | W≤ | B≤ |

| - | 0.50 | 0.15 | 17.0-20.0 | 0.5-2.5 | - | 0.2-1.0- | 0.010 |

Specific heat capacity

| θ/℃ | 17 | 100 | 200 | 280 | 408 | 500 | 700 | 800 | 900 |

| c/(J(kg`℃)) | 372.6 | 372.6 | 389.4 | 456.4 | 427.1 | 452.2 | 515.0 | 535.9 | 561.0 |

Linear expansion coefficient

| θ/℃ | 20~100 | 20~200 | 20~300 | 20~400 | 20~500 | 20~600 | 20~800 | 20~900 |

| α/10-6℃-1 | 12.1 | 12.5 | 13.4 | 14.0 | 14.3 | 14.8 | 15.8 | 16.1 |

thermal diffusivity

| θ/℃ | 24 | 100 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| Q/(10-6m2/S)) | 2.78 | 3.06 | 3.68 | 3.64 | 4.36 | 4.32 | 4.38 | 4.91 | 5.23 |

Thermal conductivity

| θ/℃ | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 |

| λ/(W/(m`℃)) | 13.38 | 17.97 | 20.27 | 22.40 | 24.62 | 26.79 | 29.05 | 31.14 | 33.44 |

product

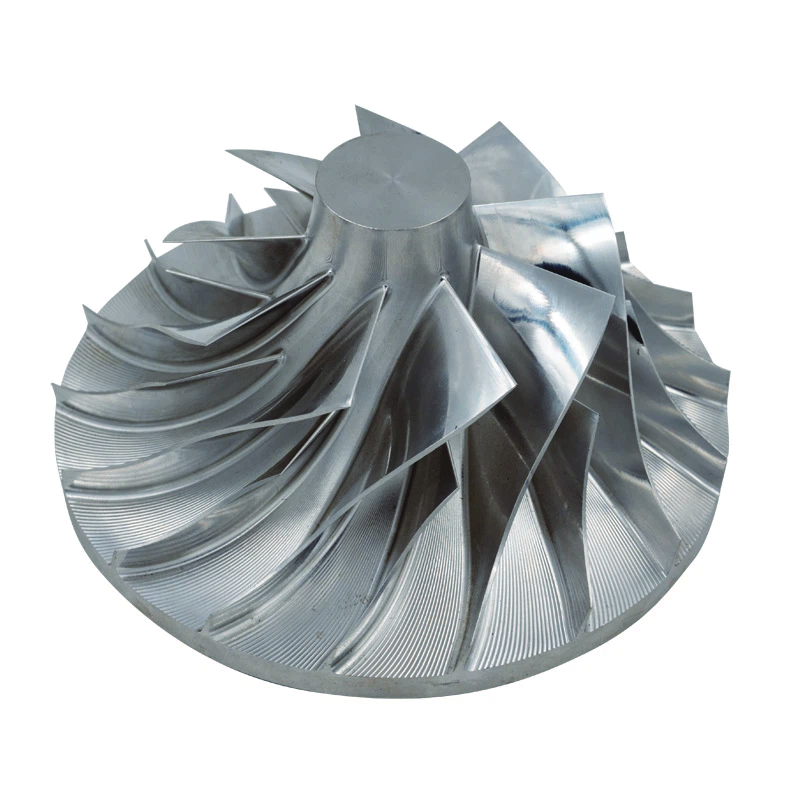

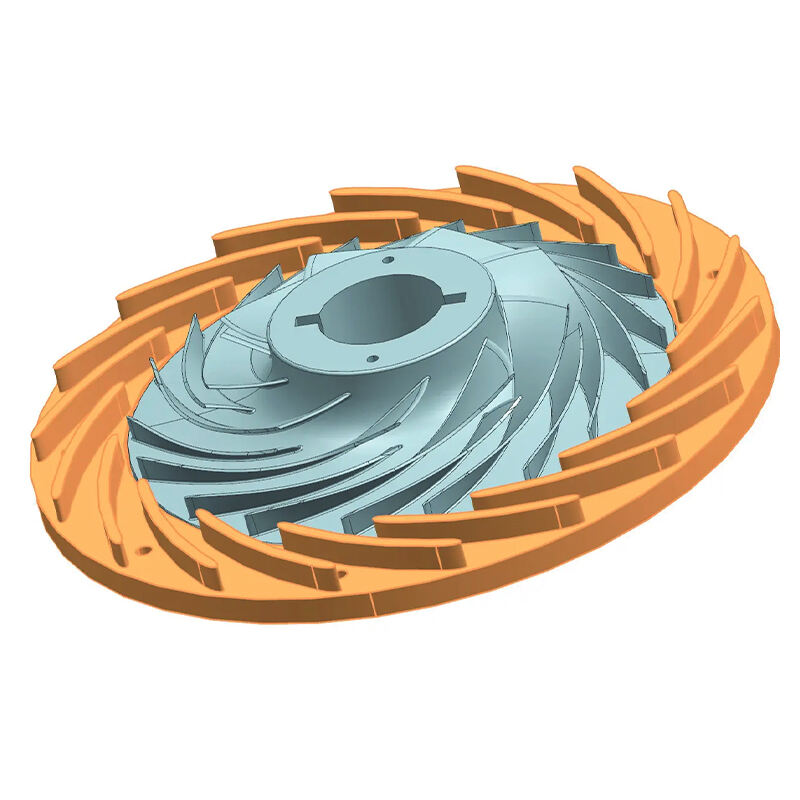

turbine wheel

turbine blade

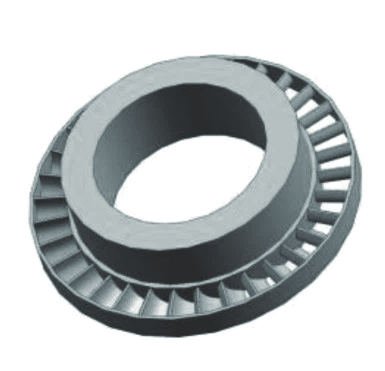

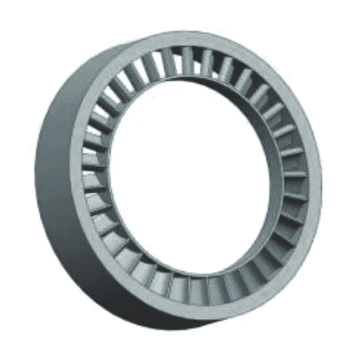

nozzle ring

compressor blade

guide vanes

diffuser

Segment

Turbine Rotor

Turbine Stator

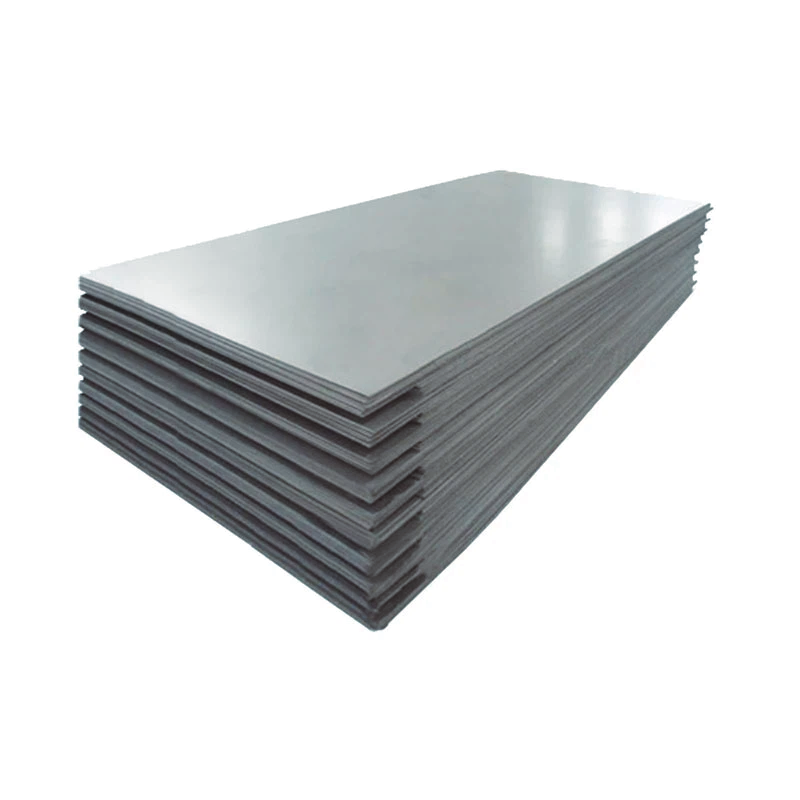

Hastelloy sheet

Hastelloy pipe

Hastelloy rod

Hastelloy bolt and nut

Hastelloy Fasteners

Hastelloy wire

spring

According to drawings or samples

Hastelloy is another family of nickel-based superalloys known for their exceptional corrosion resistance and high-temperature strength. Here's an overview of Hastelloy:

Corrosion Resistance:

Like Inconel, Hastelloy alloys are prized for their outstanding resistance to corrosion in various aggressive environments, including acids, chlorides, sulfides, and oxidizing and reducing conditions. This corrosion resistance makes Hastelloy suitable for use in chemical processing, pollution control, and marine applications.

High Temperature Performance:

Hastelloy alloys maintain their mechanical strength and integrity at elevated temperatures, making them suitable for applications in high-temperature environments such as gas turbines, aerospace components, and industrial furnaces.

Alloying Elements:

Hastelloy alloys are typically composed of nickel as the primary element, along with significant amounts of chromium, molybdenum, and other elements like cobalt, tungsten, and iron. These alloying elements contribute to the alloys' unique properties, including corrosion resistance and high-temperature strength.

Versatility:

Hastelloy alloys are available in various grades, each tailored to specific applications and operating conditions. Common grades include Hastelloy C-276, Hastelloy C-22, Hastelloy X, and Hastelloy B-2, among others. These grades offer a range of properties suitable for different environments and industries.

Applications:

Hastelloy alloys find widespread use in industries such as chemical processing, petrochemical, oil and gas, aerospace, pollution control, and pharmaceuticals. They are employed in equipment such as reactors, heat exchangers, valves, pumps, and piping systems where corrosion resistance and high-temperature performance are critical.

Fabrication:

Hastelloy alloys can be fabricated into various forms, including sheets, plates, bars, wires, tubes, and forgings, allowing for the production of complex components tailored to specific applications.

Overall, Hastelloy alloys are highly regarded for their exceptional corrosion resistance, high-temperature strength, and versatility, making them indispensable materials in industries where harsh environments and demanding operating conditions are common.

Aerospace field

Automobile and motorcycle manufacturing

Chemical industry

Marine engineering

Our professional sales team are waiting for your consultation.