Chemical Composition

| Weight % | Ni | Cr | Mo | Fe |

| Nickel Alloy C-22 | Balance | 20.0-22.5 | 12.5-14.5 | 2.0-6.0 |

Standard

Pipe and Tube: - ASTM B 619; ASTM B 775 & ASME SB 619; ASME SB 775 (Welded Pipe), ASTM B 622; ASTM B 829 & ASME SB 622; ASME SB 829 (Seamless Tube), ASTM B 626; ASTM B 751 & ASME SB 626; ASME SB 751 (Welded Tube), ASME Code Case 2226, ASME Code Case N-621, ISO 6207, DIN 17751.

Applications

The exceptional corrosion resistance of C22 has promoted its use in many different markets wherever harsh environments are encountered, including the chemical process, pharmaceutical, food processing, oil & gas, power generation, and the paper industries. CRA offers specialty alloy C22 seamless pipe & tube for use in multiple industries and applications, including:

● Chemical Processing

● Food Processing

● Pharmaceutical Industry

● Oil & Gas

● Power Generation

● Pulp & Paper Industries

Material Summary

Nickel Alloy C-22 is a versatile Ni-Cr-Mo-W alloy with better comprehensive corrosion resistance performance than other Ni-Cr-Mo alloys, including Alloy C-276, Alloy C-4 and Alloy 625. Alloy C-22 has outstanding resistance to pitting, crevice corrosion and stress corrosion cracking. It has excellent resistance to oxidizing aqueous media including wet chlorine and mixtures containing nitric acid or oxidizing acids with chloride ions. It also offers optimum resistance to environments where reducing and oxidizing conditions are encountered in process streams.

product

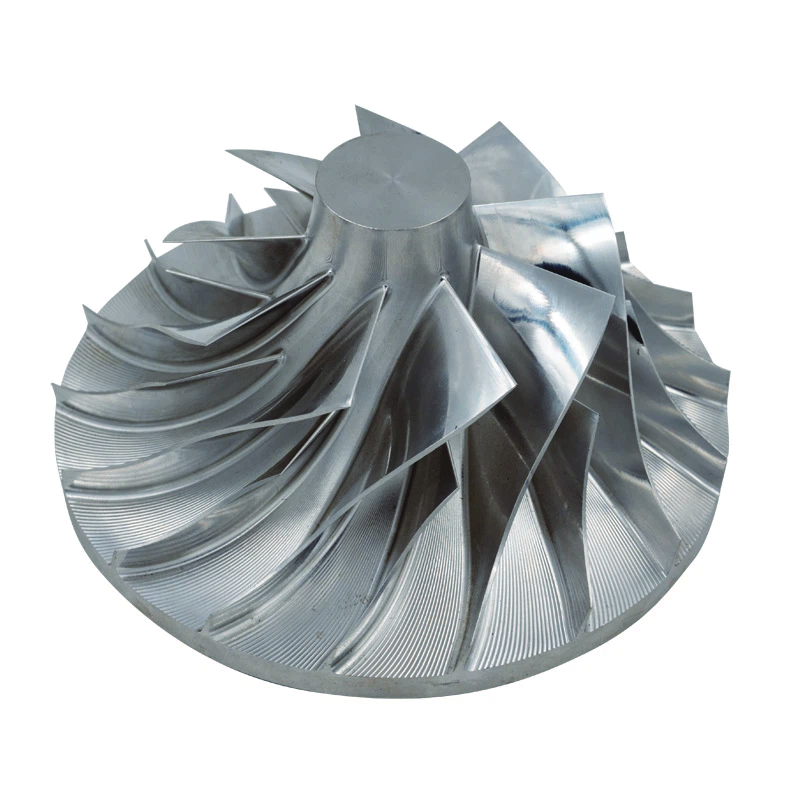

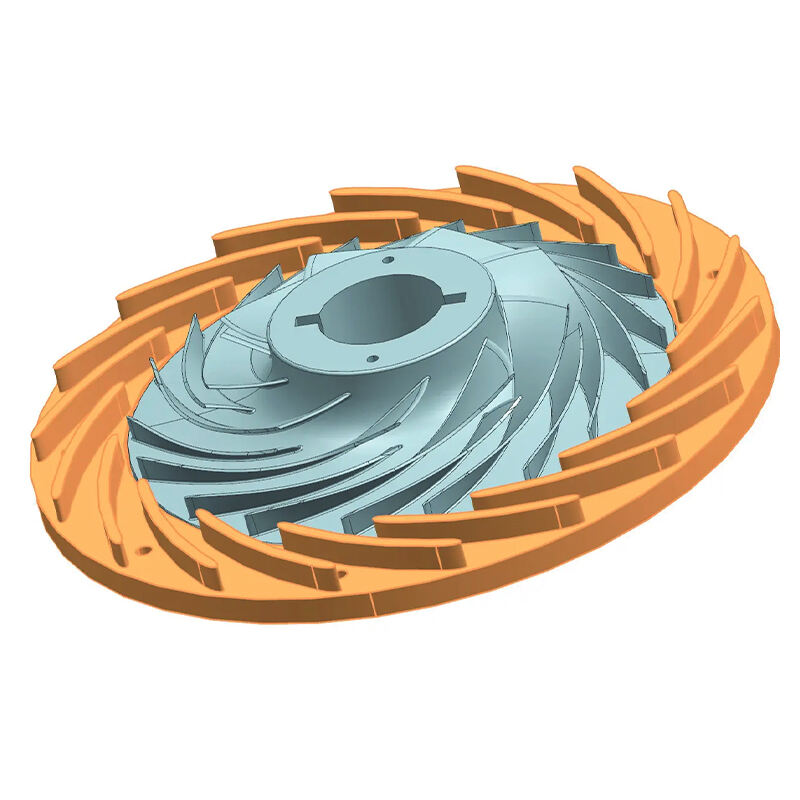

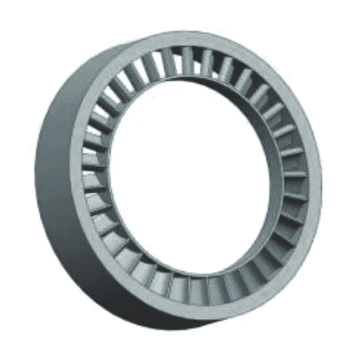

Inconel wheel

Inconel blade

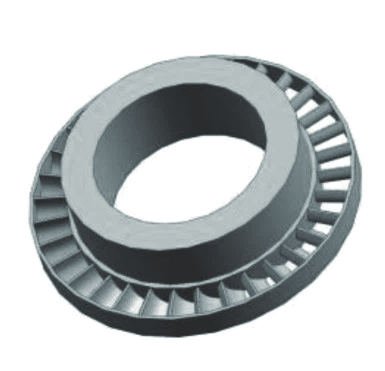

nozzle ring

compressor blade

guide vanes

diffuser

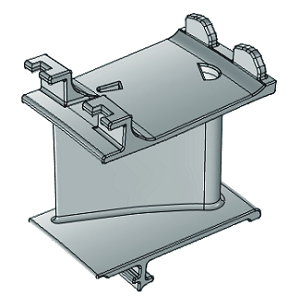

Segment

Inconel Rotor

Turbine Stator

Inconel sheet

Inconel pipe

Inconel rod

Inconel bolt and nut

Inconel Fasteners

Inconel wire

spring

According to drawings or samples

Aerospace field

Automobile and motorcycle manufacturing

Chemical industry

Marine engineering

Our professional sales team are waiting for your consultation.